Rotor core and high-efficiency frequency conversion speed regulating permanent magnet synchronous motor

A technology of rotor iron core and iron core, applied in the field of high-efficiency variable frequency speed-regulating permanent magnet synchronous motors, can solve the problems of difficult assembly and positioning of permanent magnet 1′, increased structural risk coefficient, and influence on motor performance, so as to improve the utilization rate of materials , long service life and high rotor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

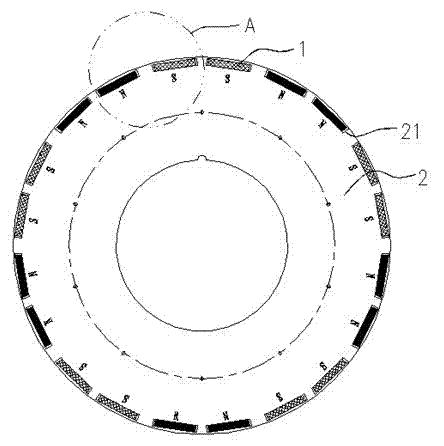

[0035] Such as image 3 As shown, a rotor core includes a core body 2 and a plurality of N pole and S pole permanent magnets 1 .

[0036] The iron core body 2 is formed by stacking multiple rotor punches. Each rotor punch is formed by punching and cutting a long strip-shaped or square silicon steel plate according to the size. After stacking, each rotor punch is fixed by riveting or welding. connected as one.

[0037] The iron core body 2 is provided with 2n sets of magnetic steel slot groups uniformly distributed around the center on the part close to the outer surface, n is a positive integer, in this embodiment, n takes a value of 5, in practice, according to the rotor size and needs Set n. The permanent magnet magnets 1 of the same polarity are arranged in each magnet steel slot 21 in the same group, and the permanent magnet magnets 1 between groups are alternately arranged with S poles and N poles in sequence.

[0038] Each set of magnetic steel slots includes at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com