Air-gap-adjustable disc-type motor and control method thereof

A disc motor and control method technology, which is applied in the direction of single motor speed/torque control, control of mechanical energy, electrical components, etc. High reliability, suitable for large-scale promotion, and the effect of improving vehicle climbing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

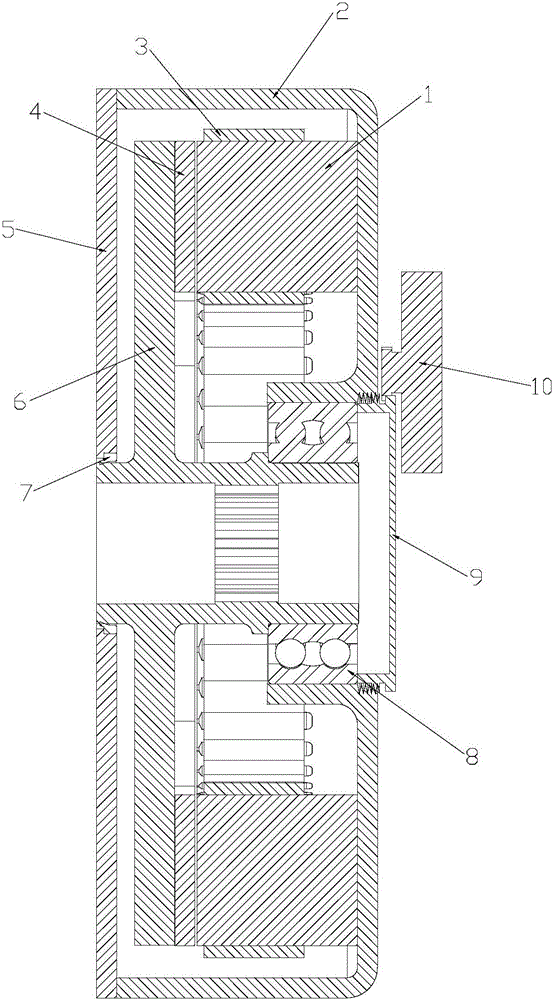

[0026] figure 1 It is a structural schematic diagram of a disc motor with an adjustable air gap provided by a specific embodiment of the present invention. The disc motor with adjustable air gap includes a casing 2, a stator 1 set inside the casing 2, a stator winding 3 set outside the stator 1, a rotor 6 coaxially set with the stator 1, and a bearing connected to the rotor 6 8. The bearing cover 9 connected to the bearing 8 arranged on the outside of the casing 2, the turbine motor 10 for driving the bearing cover 9 to rotate, the permanent magnet 4 arranged between the stator 1 and the rotor 6, and formed with the casing 2 The end cap 5 of the cavity, wherein the end cap 5 has a housing portion, and the dust ring 7 is sleeved in the housing portion to prevent dust and / or impurities from entering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com