Bidirectional magnetic circuit coupling type magnetic field modulation direct drive motor for electric automobile

A technology for electric vehicles and magnetic field modulation, applied in electric vehicles, magnetic circuit shape/style/structure, motors, etc., can solve the problem that the permanent magnetic field is difficult to adjust low-speed and high-torque characteristics, and achieve low-speed and high-torque characteristics obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

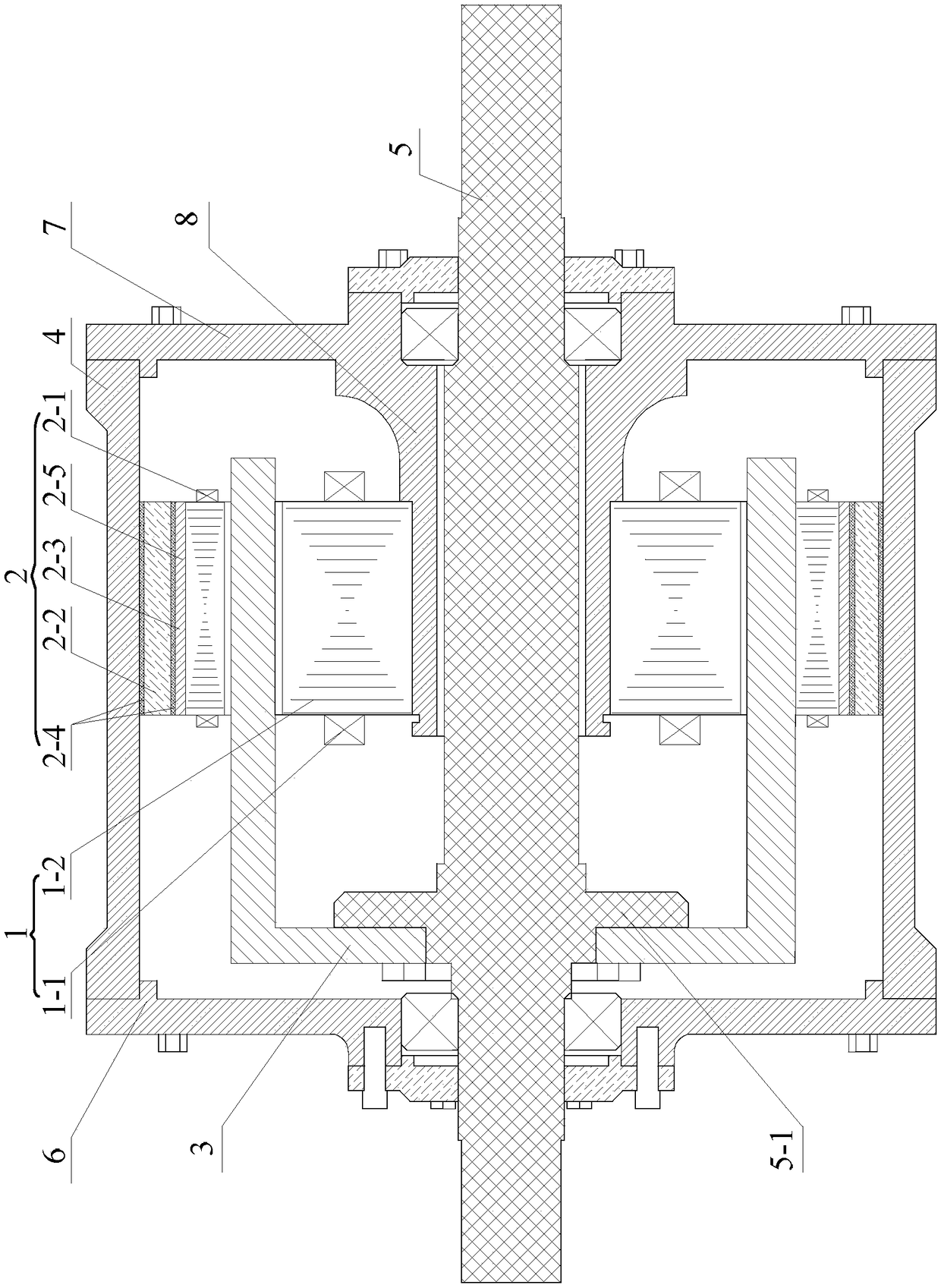

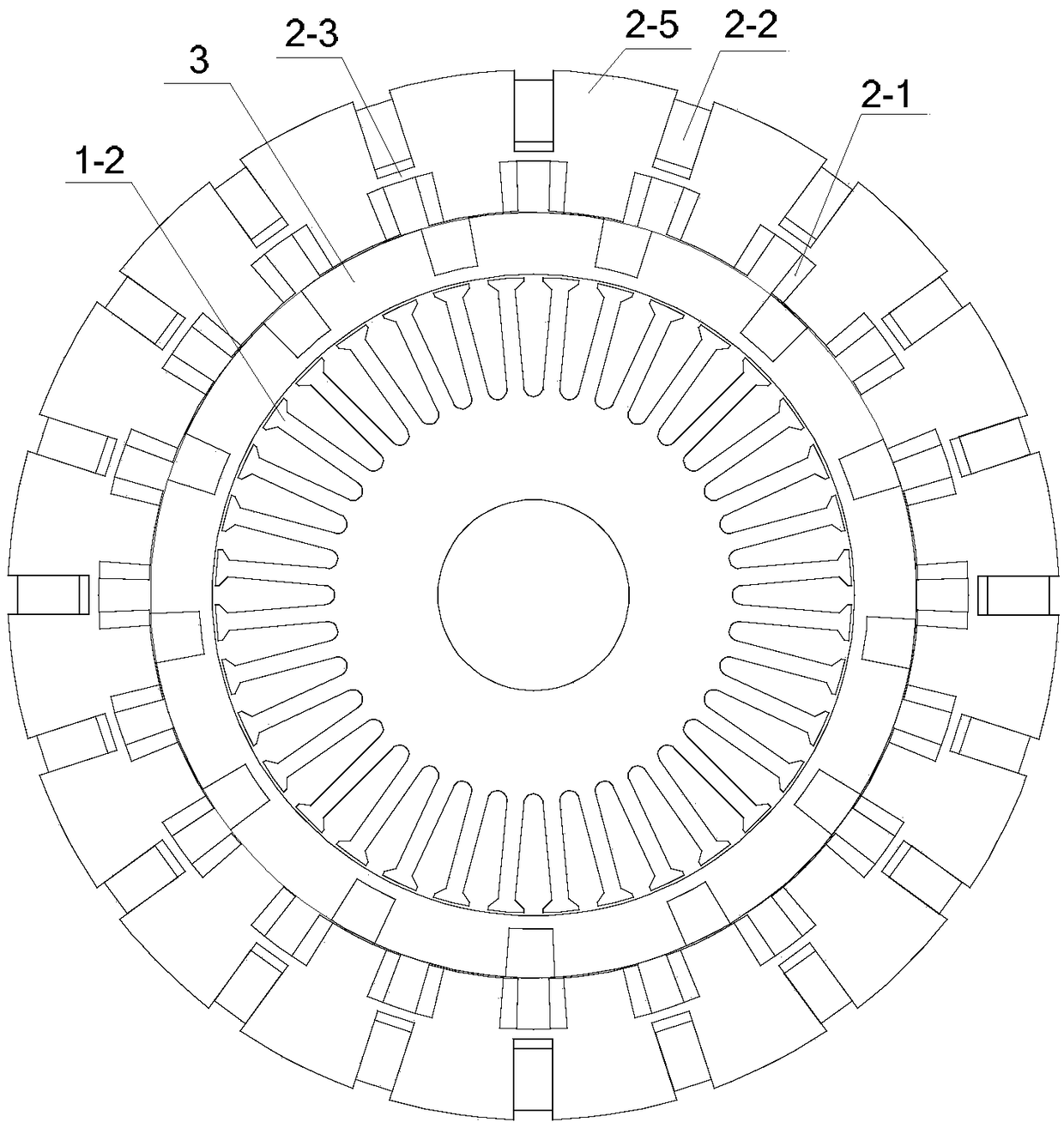

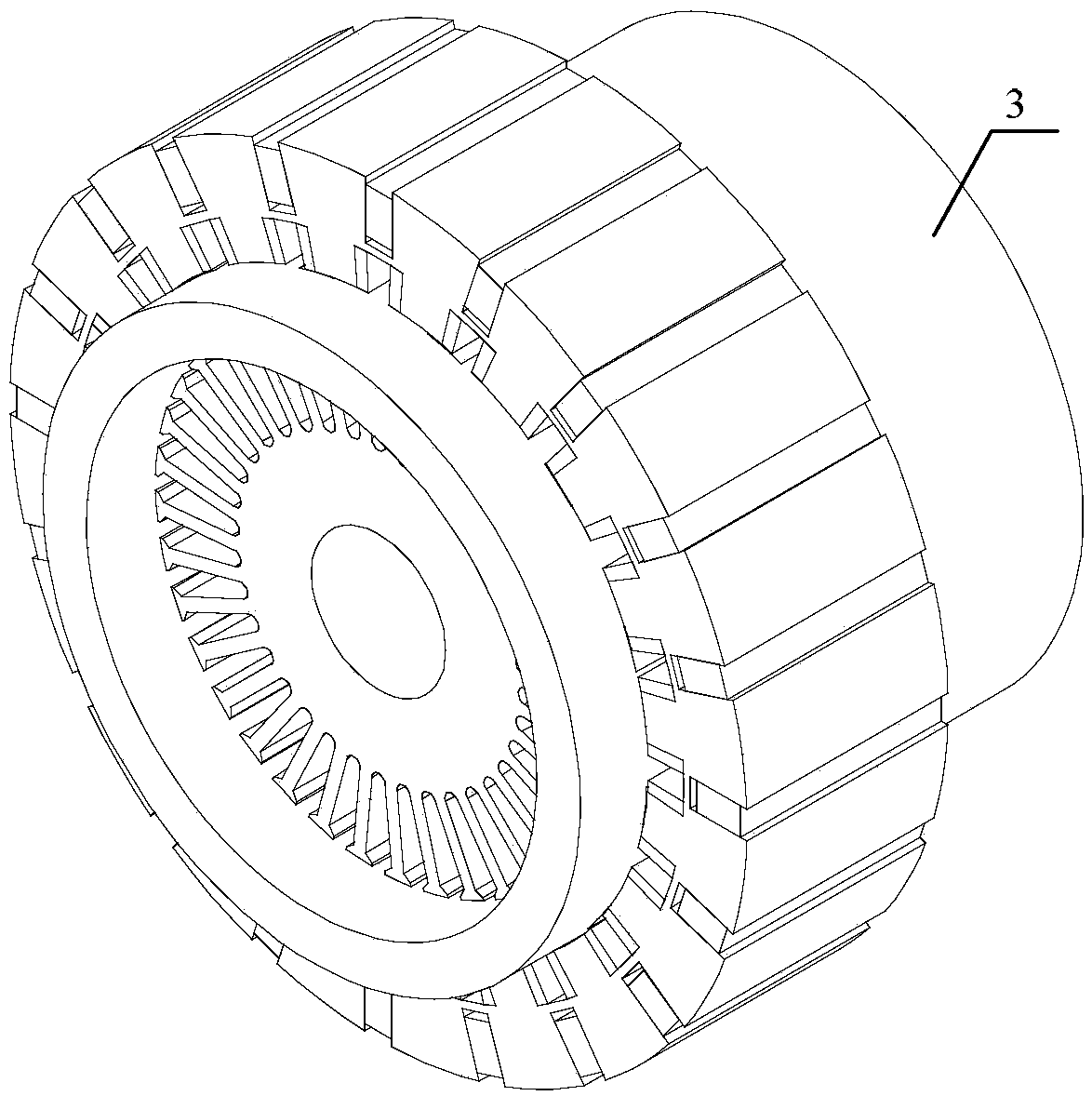

[0031] Specific implementation mode one: refer to Figures 1 to 12 Describe this embodiment in detail. The two-way magnetic circuit coupled magnetic field modulation direct drive motor for electric vehicles described in this embodiment includes: an inner stator 1, an outer stator 2, a cup-shaped rotor 3, a casing 4 and an output shaft 5;

[0032] The casing 4 is a cylindrical structure, the two ends of the casing 4 are respectively blocked by the left end cover 6 and the right end cover 7, and the centers of the left end cover 6 and the right end cover 7 are both provided with through holes, and the output shaft 5 passes through the two end covers The through hole on the top runs through both ends of the casing 4, so that the middle section of the output shaft 5 is located inside the casing 4, and the two ends of the output shaft 5 are positioned outside the casing 4. Between the left end cover 6 and the output shaft 5, between the right end cover 7 and the output shaft 5, all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com