Bi-directionally magnetically coupled and axially excited and limited rotating-shaft piezoelectric generator

An axial and piezoelectric technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve low reliability, piezoelectric vibrator fragmentation, discomfort, etc. problems, to achieve the effect of high reliability, no contact impact and noise, and strong speed adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

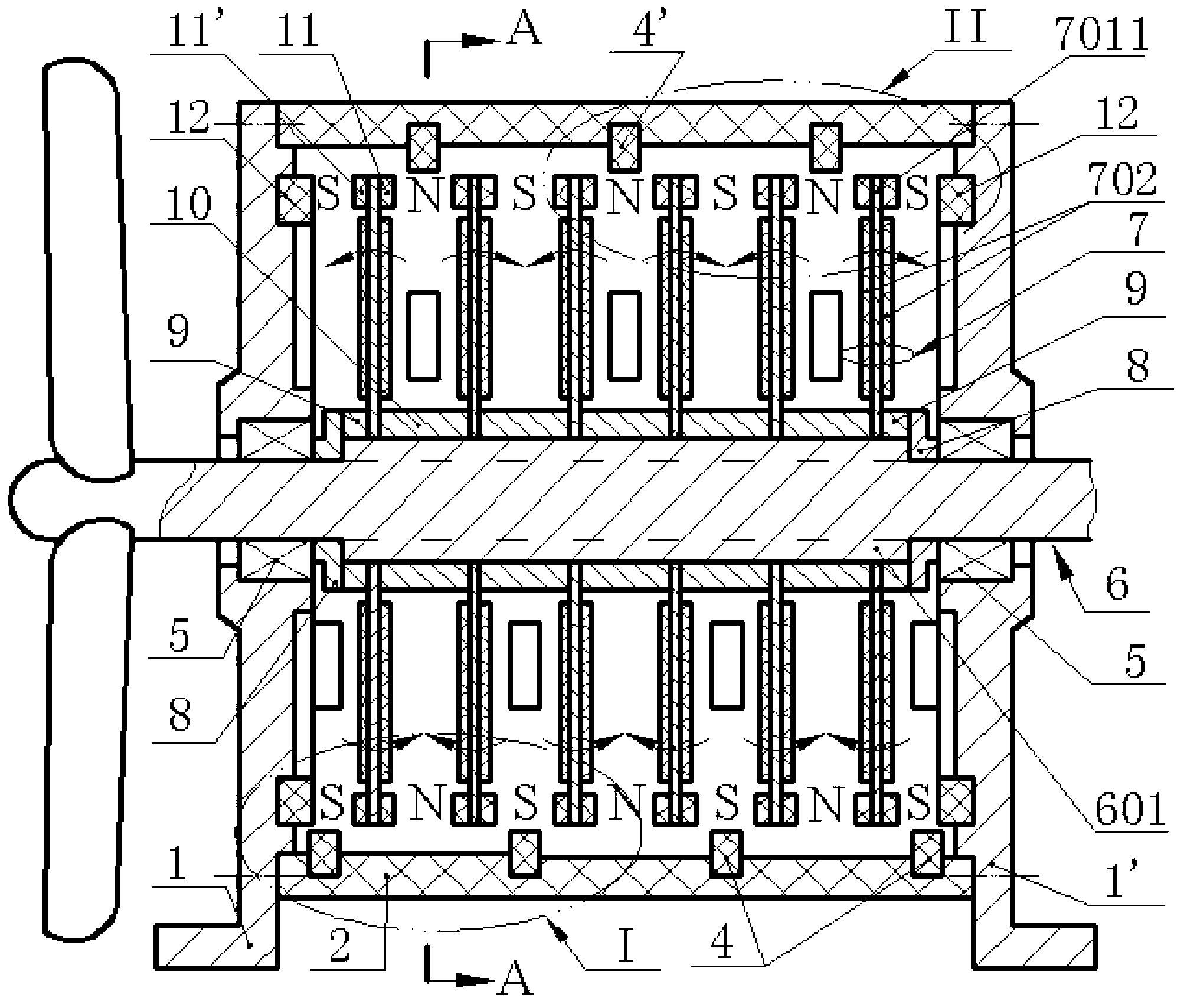

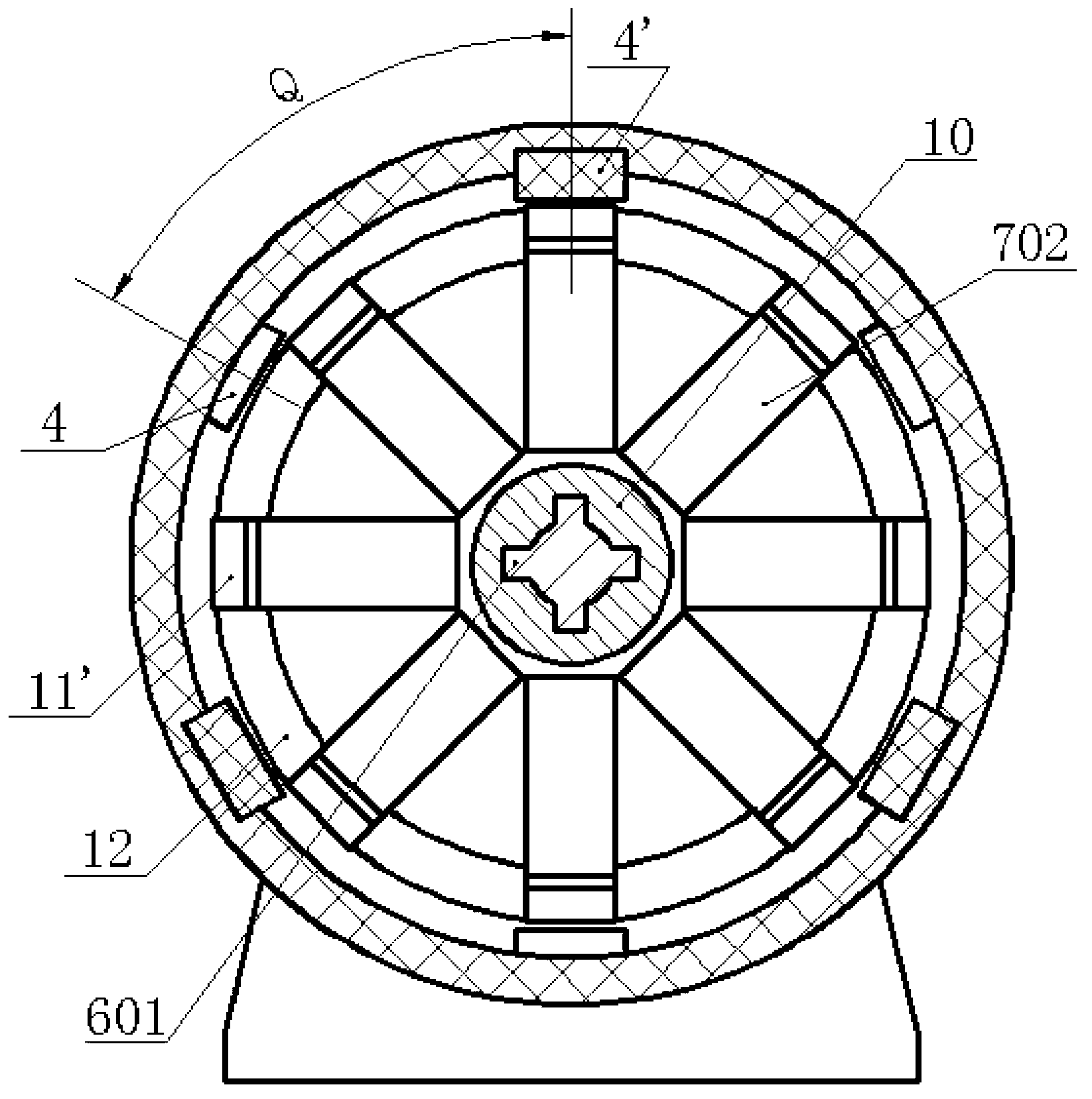

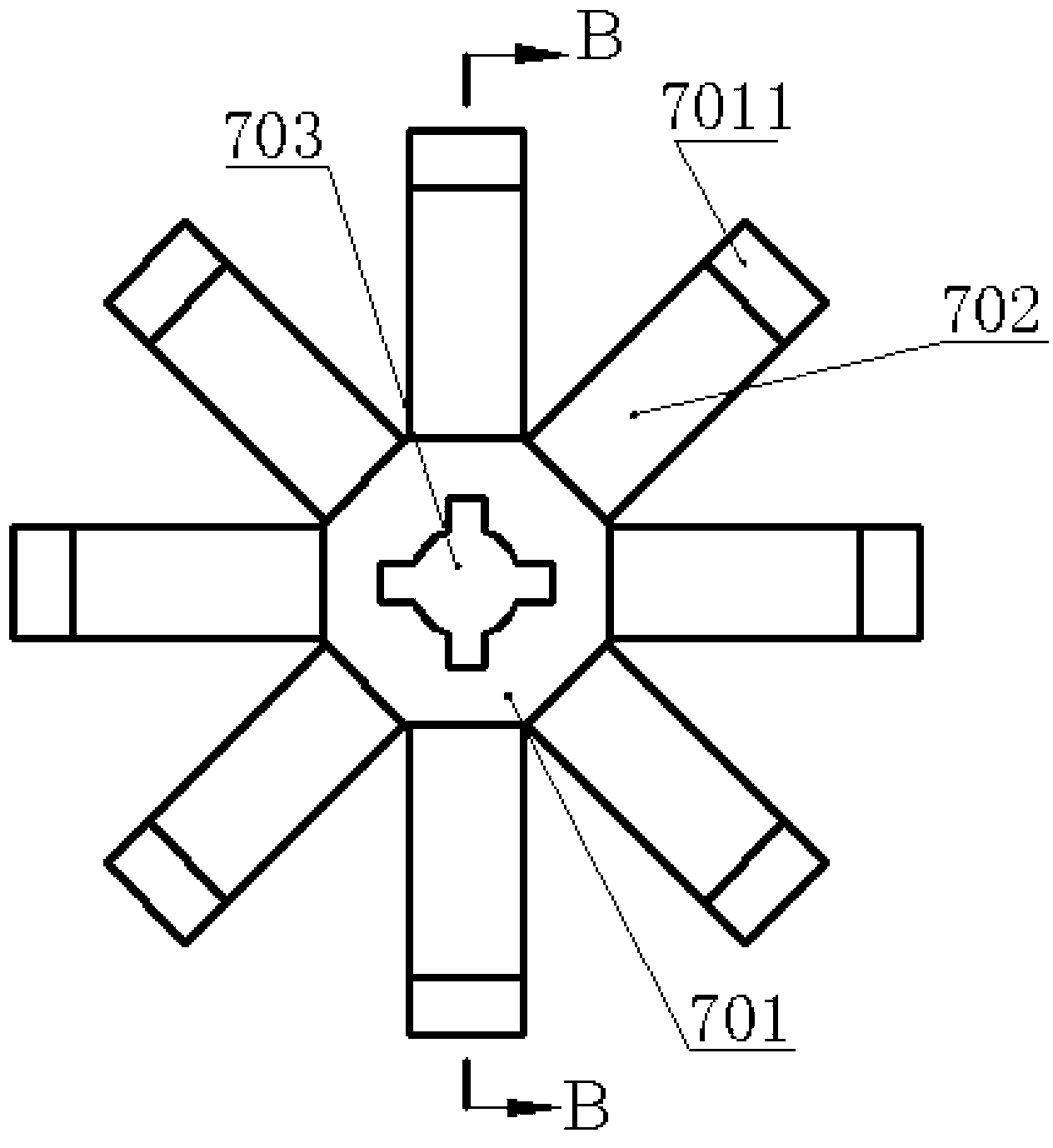

[0018] The cylinder 2 is fixedly connected by screws between the two bearing seats 1 and 2 1', and multiple sets of fixed magnets 4 and 2 4' are alternately inlaid on different cross-sections of the inner wall of the cylinder 2. The magnetic poles of the first fixed magnet 4 and the second fixed magnet 4' are installed along the radial direction of the cylinder 2, and the directions of the magnetic poles are opposite; 5 and magnetic ring 12, and the magnetic ring 12 on the bearing seat 1 and bearing seat 2 1' points to the magnetic pole polarity in the cylinder 2 and the adjacent moving magnet 4 or moving magnet 2 4' points to the circle The magnetic poles in the cylinder 2 have the same polarity; the main shaft 6 is installed on the two bearing seats 1 and 1' through the two bearings 5, and the spline 601 of the main shaft 6 is covered with a piezoelectric transducer device 7, each group of piezoelectric transducers 7 is crimped between the two bearings 5 by a pair of stepp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com