Fodder feeding device for livestock breeding

A feed and storage trough technology, which is applied in the field of animal husbandry, can solve the problems of reducing labor intensity, reducing labor load, and high labor intensity, and achieves the effects of low labor intensity, improved efficiency, and small labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

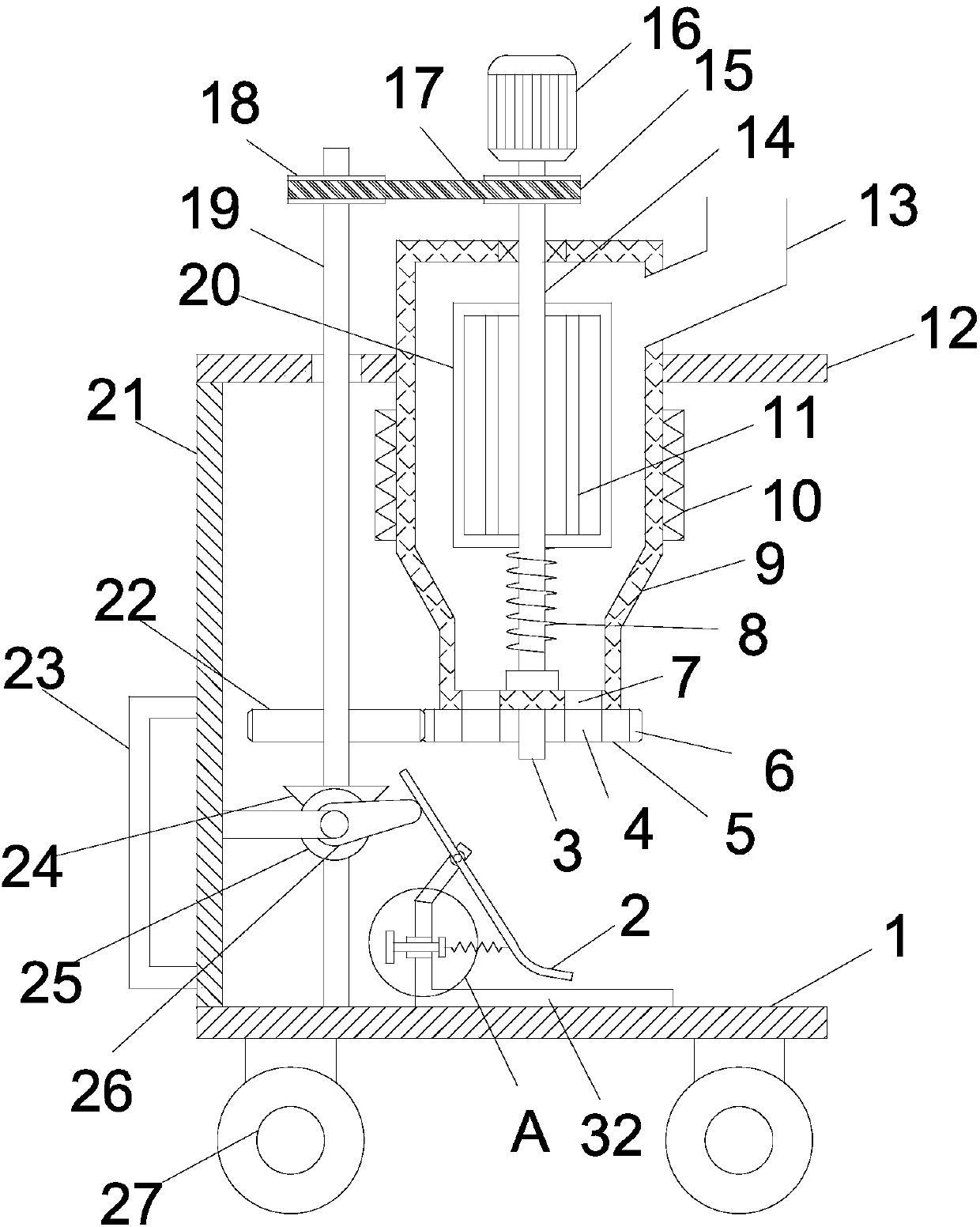

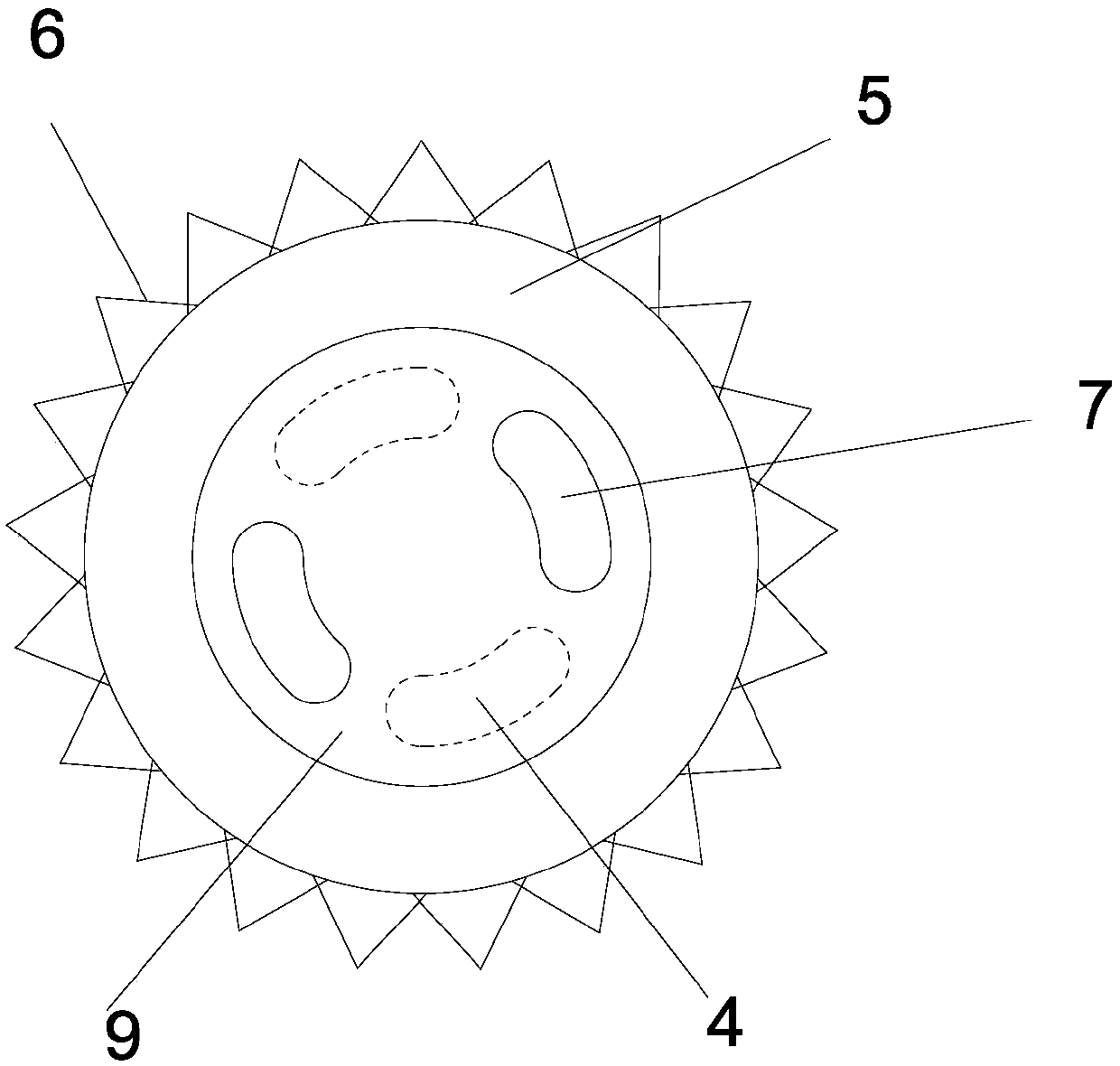

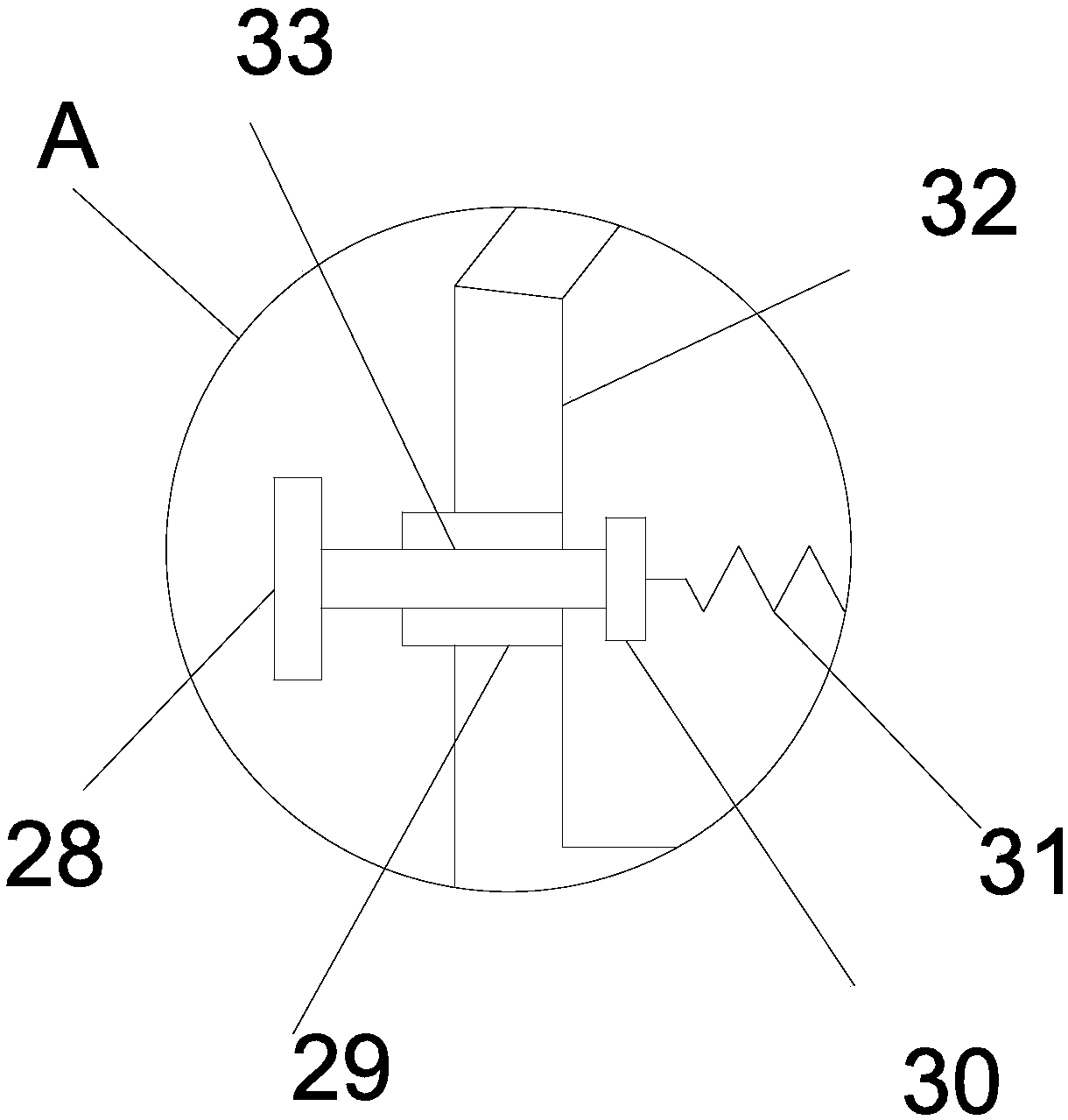

[0019] see Figure 1-3 , a feed feeding device for animal husbandry, comprising a base plate 1, a vertical plate 21 is vertically fixedly installed on the base plate 1, and a horizontal plate 12 is horizontally fixedly installed on the vertical plate 21; the bottom of the base plate 1 is provided with several Walking wheels 27, vertical plate 21 side walls are welded and fixedly installed with push-pull rods 23, vertically fixedly installed with mixing bucket 9 on the horizontal plate 12, feeding pipe 13 is installed on the side walls of mixing bucket 9, and the outer side walls of mixing bucket 9 An electric heating plate 10 is arranged on the top, and a drive shaft 14 is vertically rotated in the mixing tank 9. The surface of the drive shaft 14 is located in the inside of the mixing tank 9 and is provided with a stirring frame 20. The stirring frame 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com