Automatic pin inserting machine for transformer frameworks

A technology of transformer skeleton and pin insertion machine, which is used in inductor/transformer/magnet manufacturing, coil manufacturing, electrical components, etc. The effect of pin quality and high feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

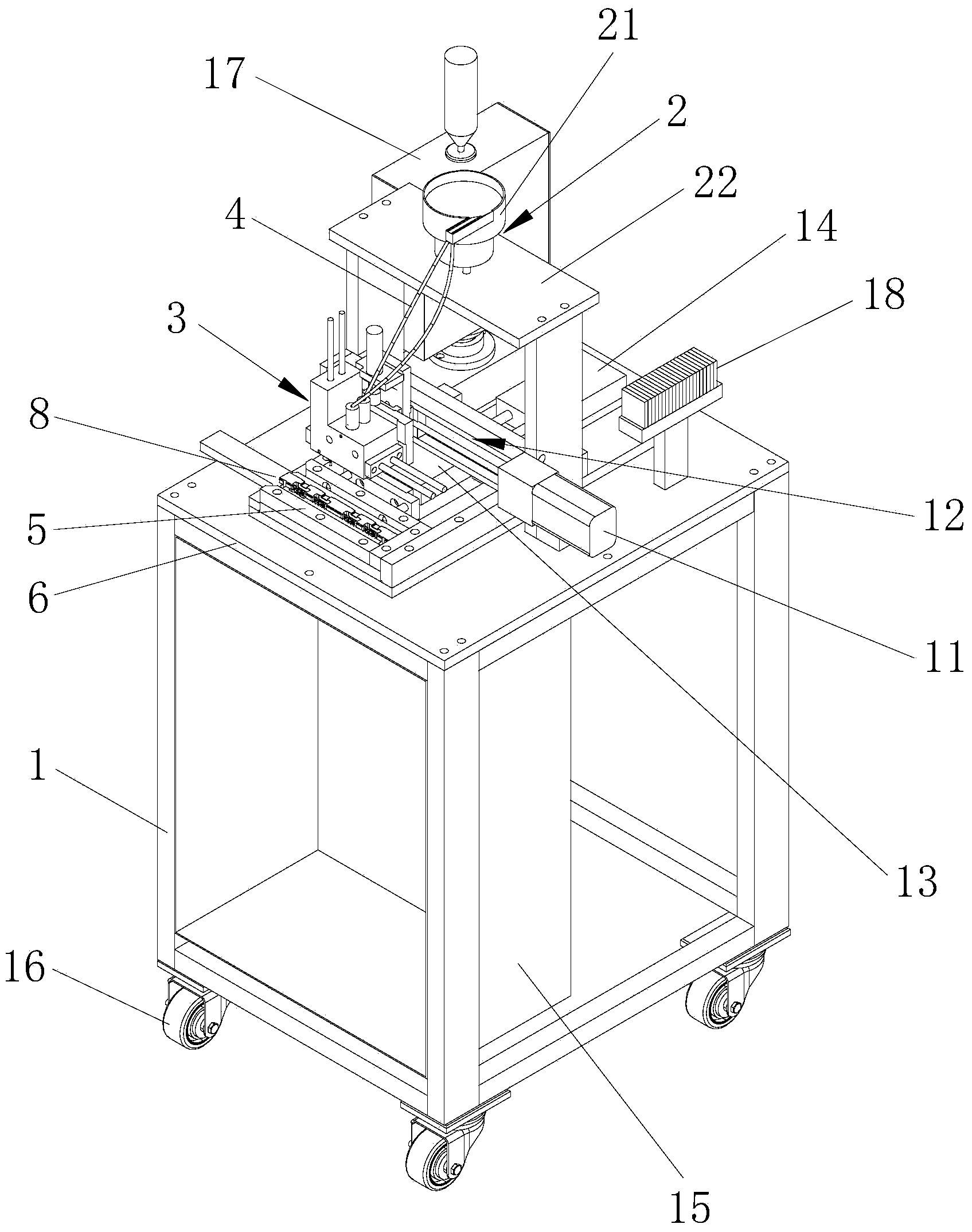

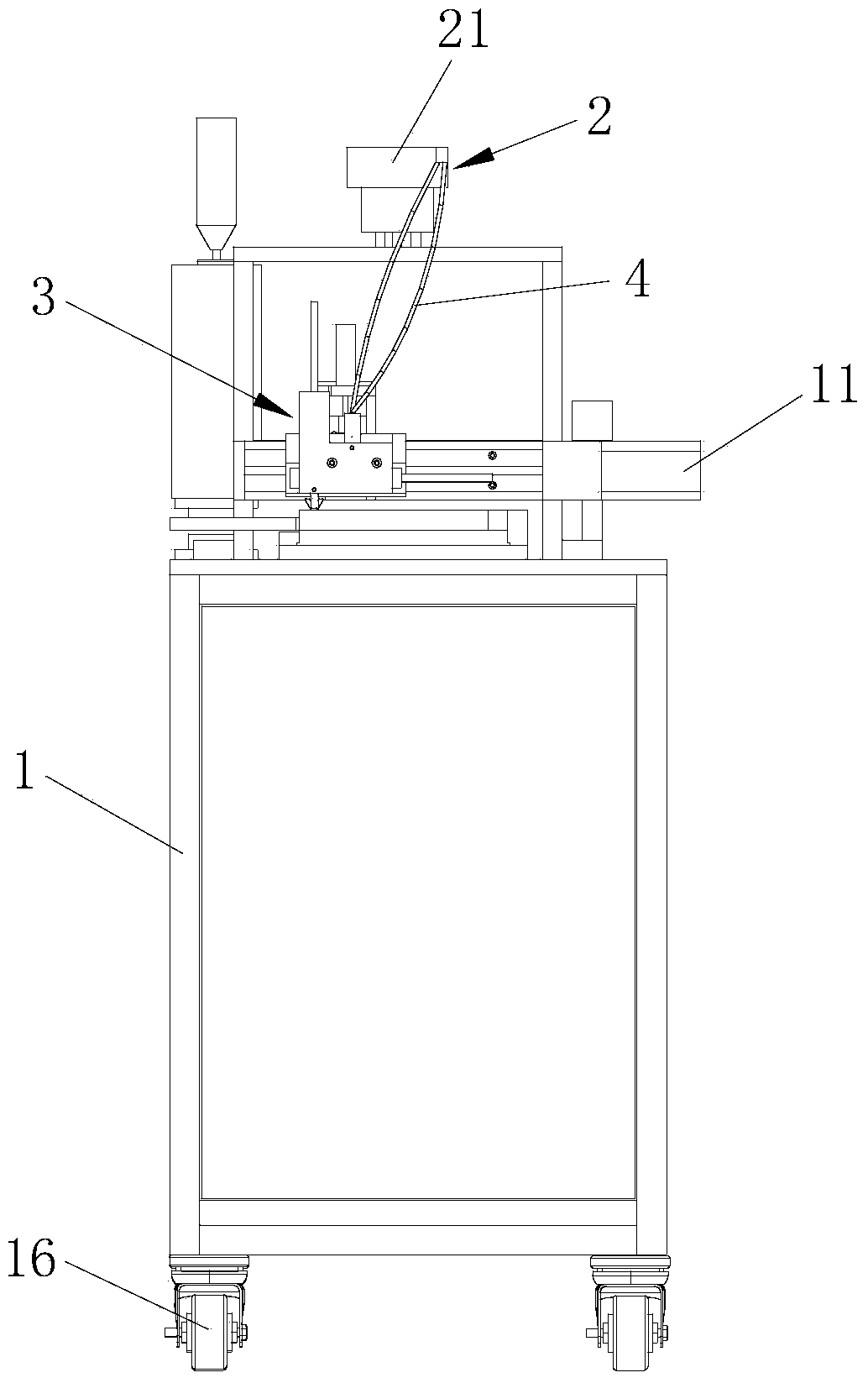

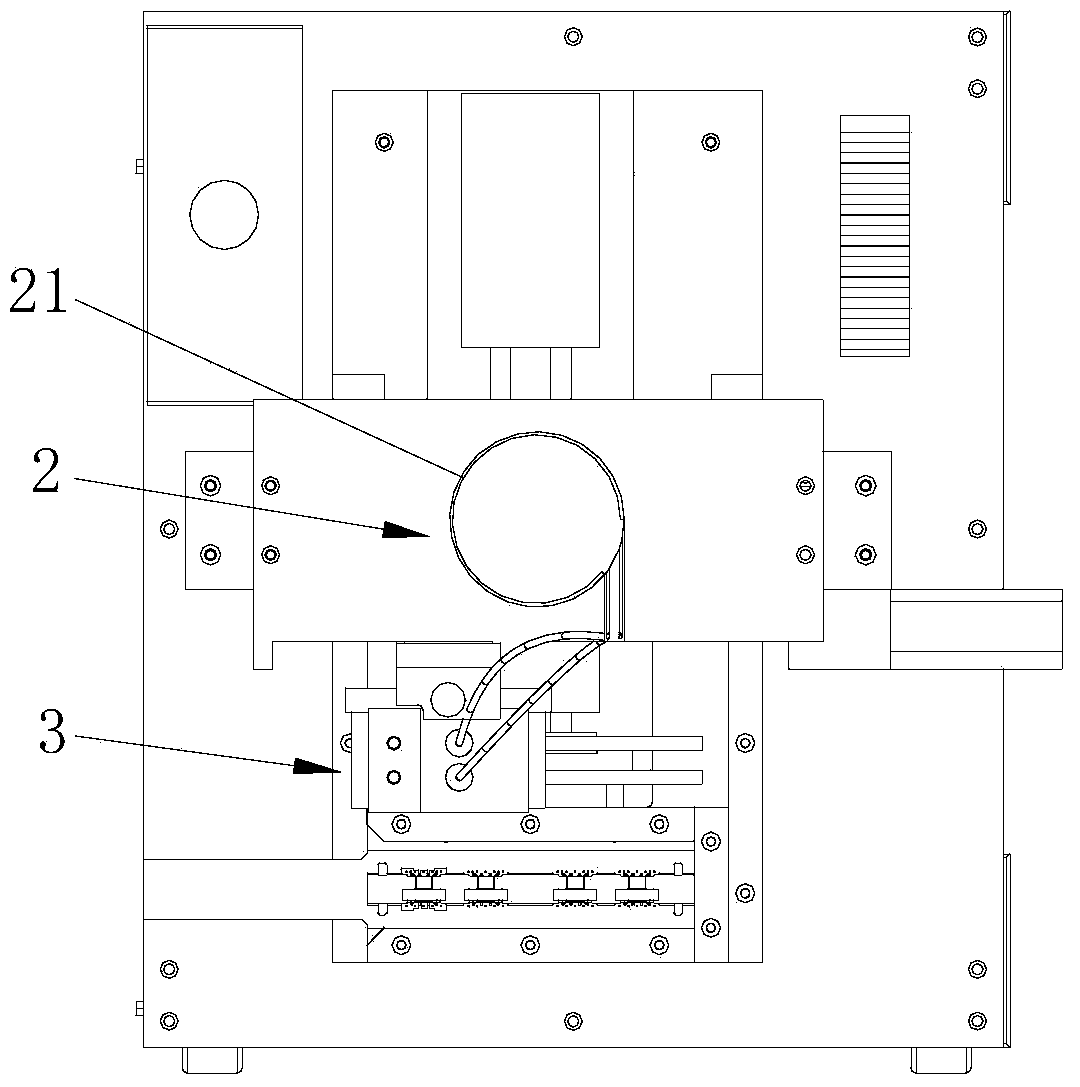

[0027] Please refer to Figure 1-7 , the transformer skeleton automatic needle insertion machine of the present invention comprises a frame 1, a vibrating feeding device 2 and a pin insertion device 3 are installed on the frame 1, and the discharge port of the vibrating feeding device 2 passes through the feed pipe 4 and the pin insertion device 3. The feeding port is connected, wherein the feeding pipe 4 is a transparent plastic hose, and the diameter of the feeding pipe 4 is slightly larger than the diameter of the needle 7 to be conveyed, so that the needles 7 can fall into the feeding pipe 4 one by one. Arranged head to tail, the needles 7 are sent to the pin insertion device 3 continuously and rapidly, and the movement of the needle insertion device 3 will not affect the feeding of the feeding tube 4 .

[0028] The needle insertion device 3 includes a needle inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com