Full-automatic intelligent opening, sealing, packing and stacking integrated machine

A fully automatic, all-in-one technology, used in packaging machines, packaging automatic control, packaging, etc., can solve problems such as increased working time, poor positioning accuracy and flexibility, box damage, etc., to avoid position offset and protect a stable environment. , the effect of saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

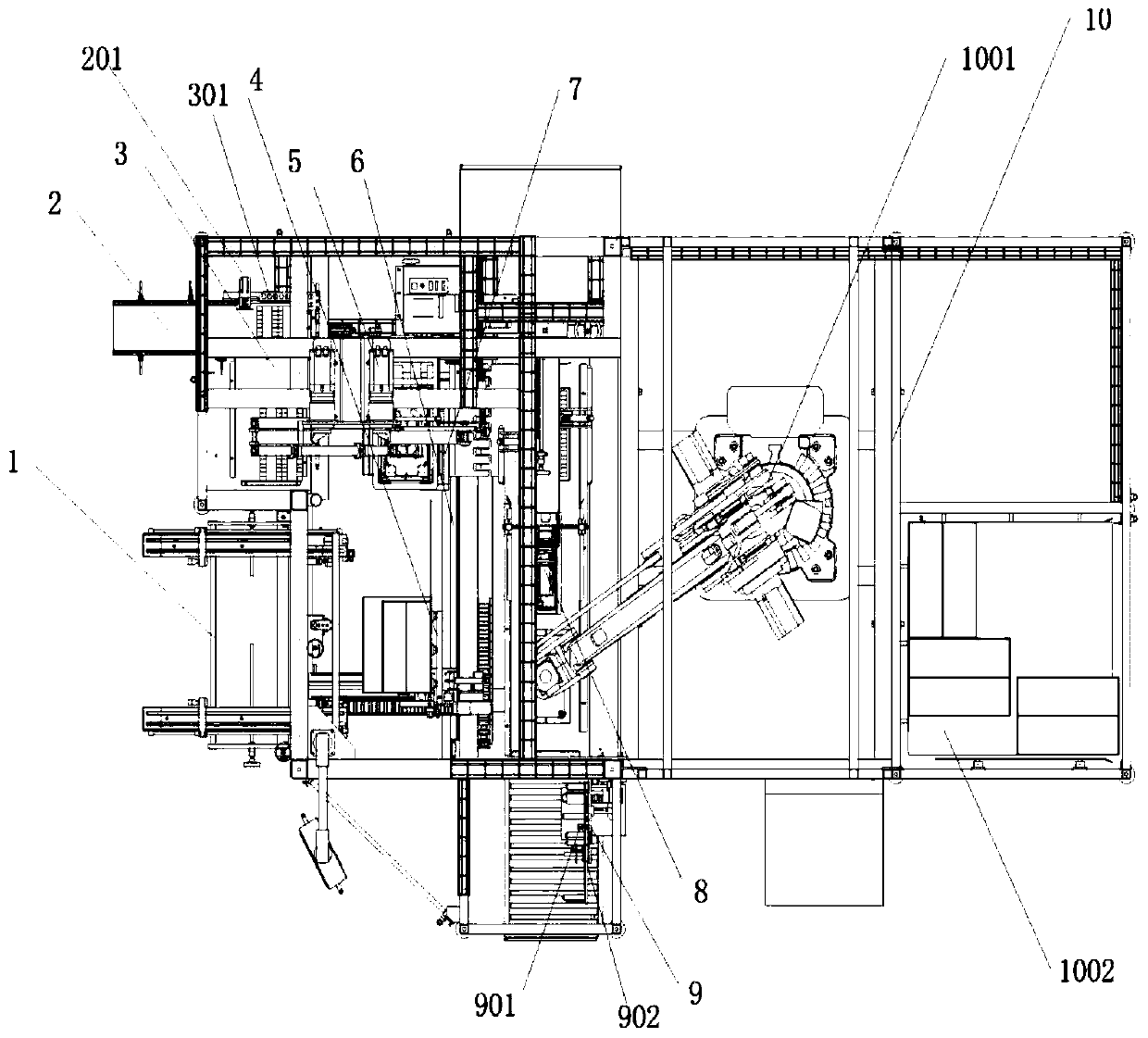

[0037] see Figure 1-9As shown, a fully automatic intelligent unpacking and palletizing integrated machine, including article sorting part, automatic unpacking and sealing part, carton labeling and detection part, carton palletizing processing part and PLC control system equipped with an intelligent control panel, in,

[0038] The article sorting part includes in turn the feeding conveying mechanism 2 for material transfer, the material sorting platform 3 for sorting the required boxed articles and its subsidiary mechanisms. The feeding conveyor 201 and the automatic material sorting mechanism 301 installed at the output port of the feeding conveyor 201;

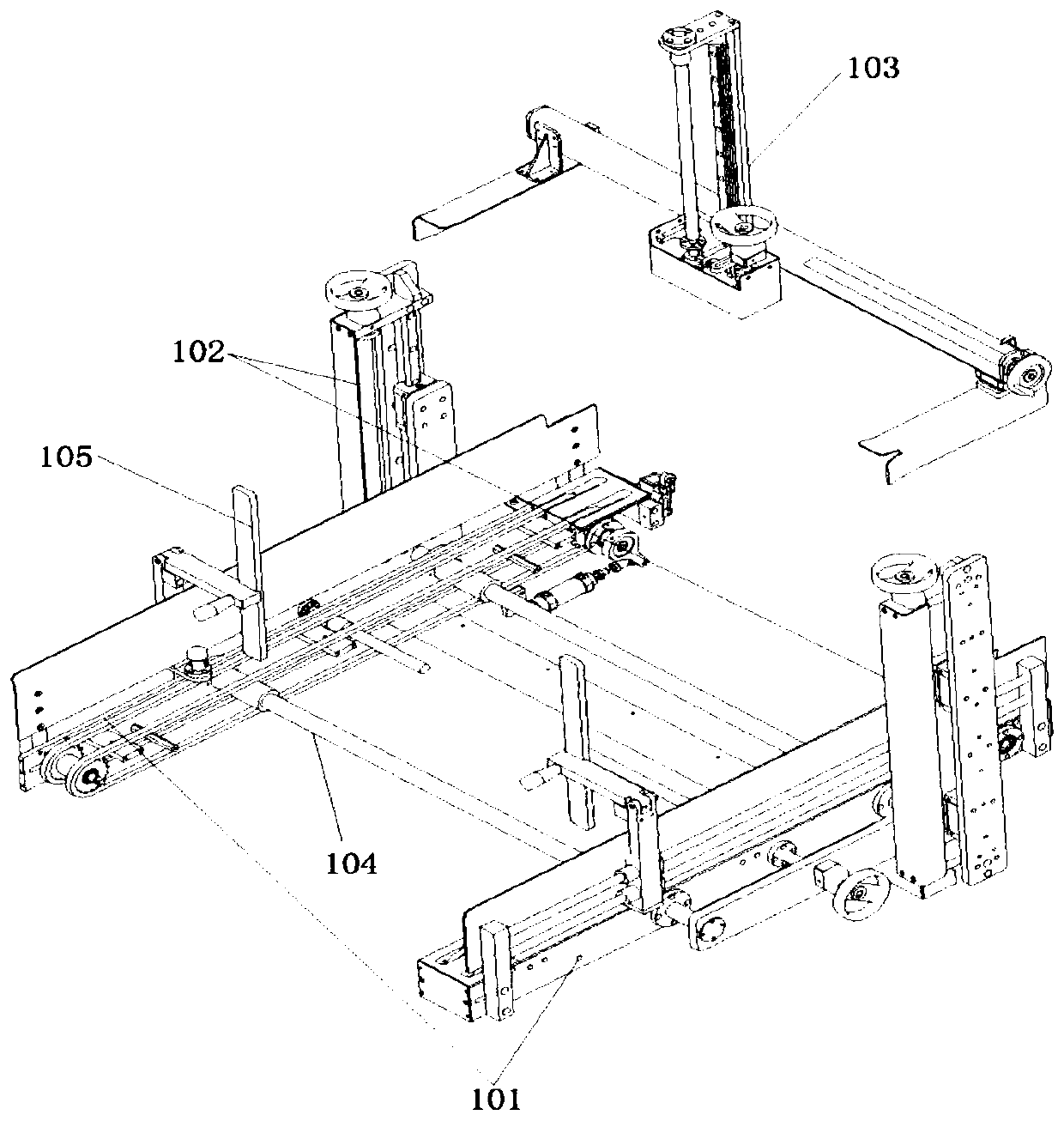

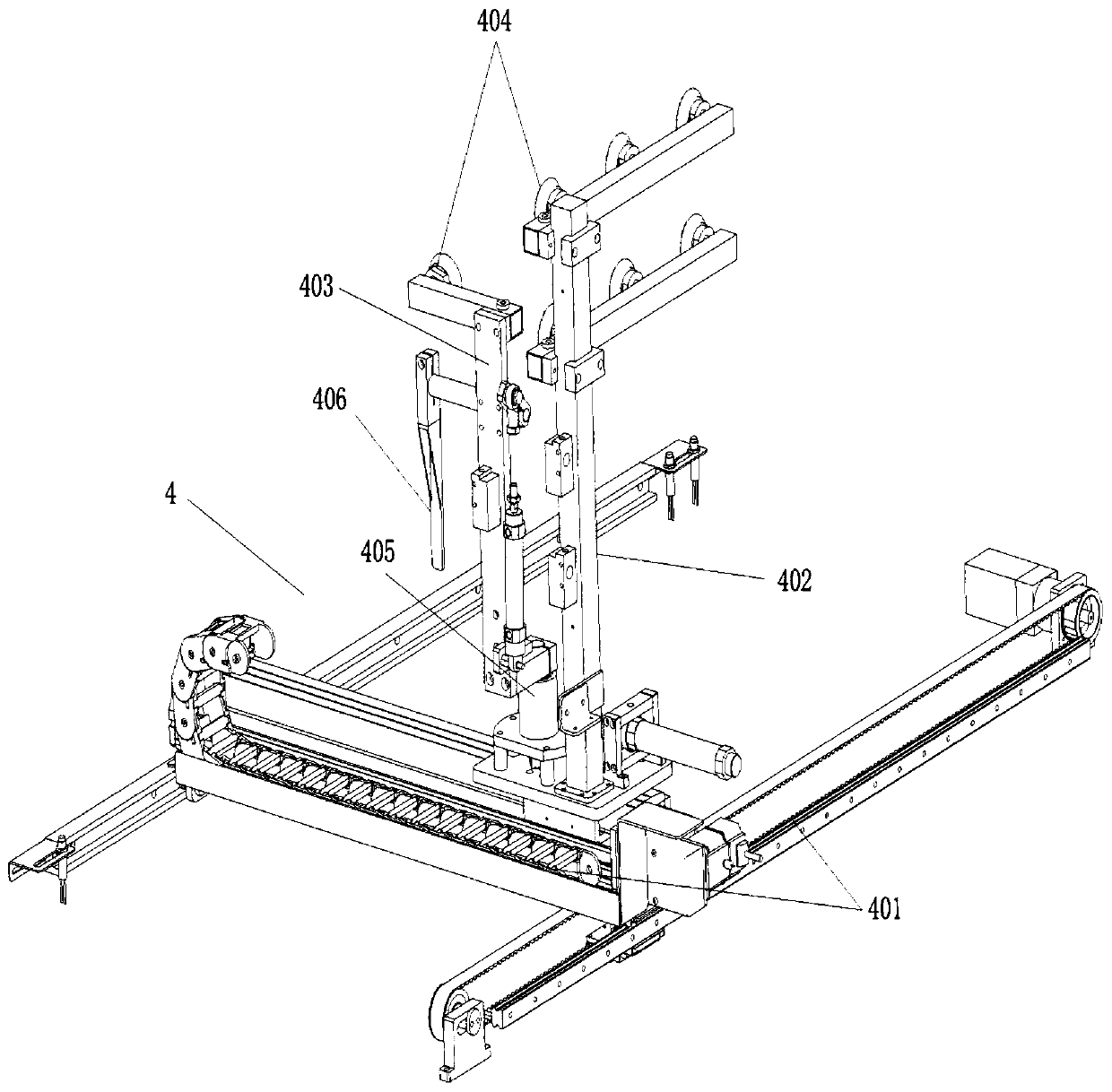

[0039] The automatic box opening and packing part includes box storage mechanism 1, servo box opening mechanism 4, servo box packing mechanism 5, box pushing mechanism 6, box supporting mechanism 7 and box sealing mechanism 8, and box storage mechanism 1 stacks flat carton boards for storage. , the cartons are pushed into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com