Shoe shole and method for making the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

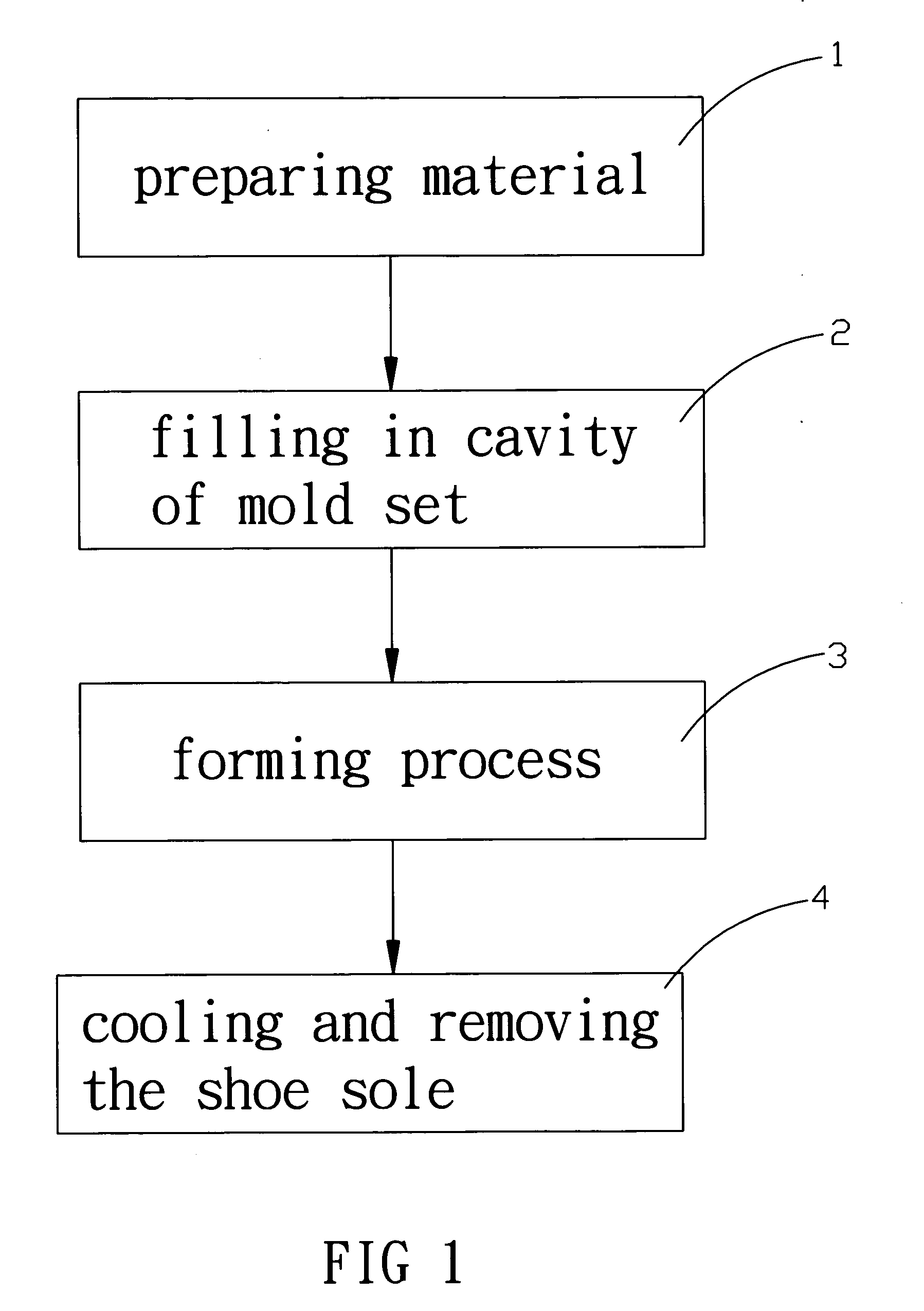

[0015] Referring to FIGS. 1 to 3, the method for making the shoe sole 30 of the present invention comprises the following steps which are:

[0016] Step 1: Preparing Material

[0017] Short and cylindrical particles 10 made of Ethylene Vinyl Acetate for example are prepared.

[0018] Step 2: Filling in Cavity of Mold Set

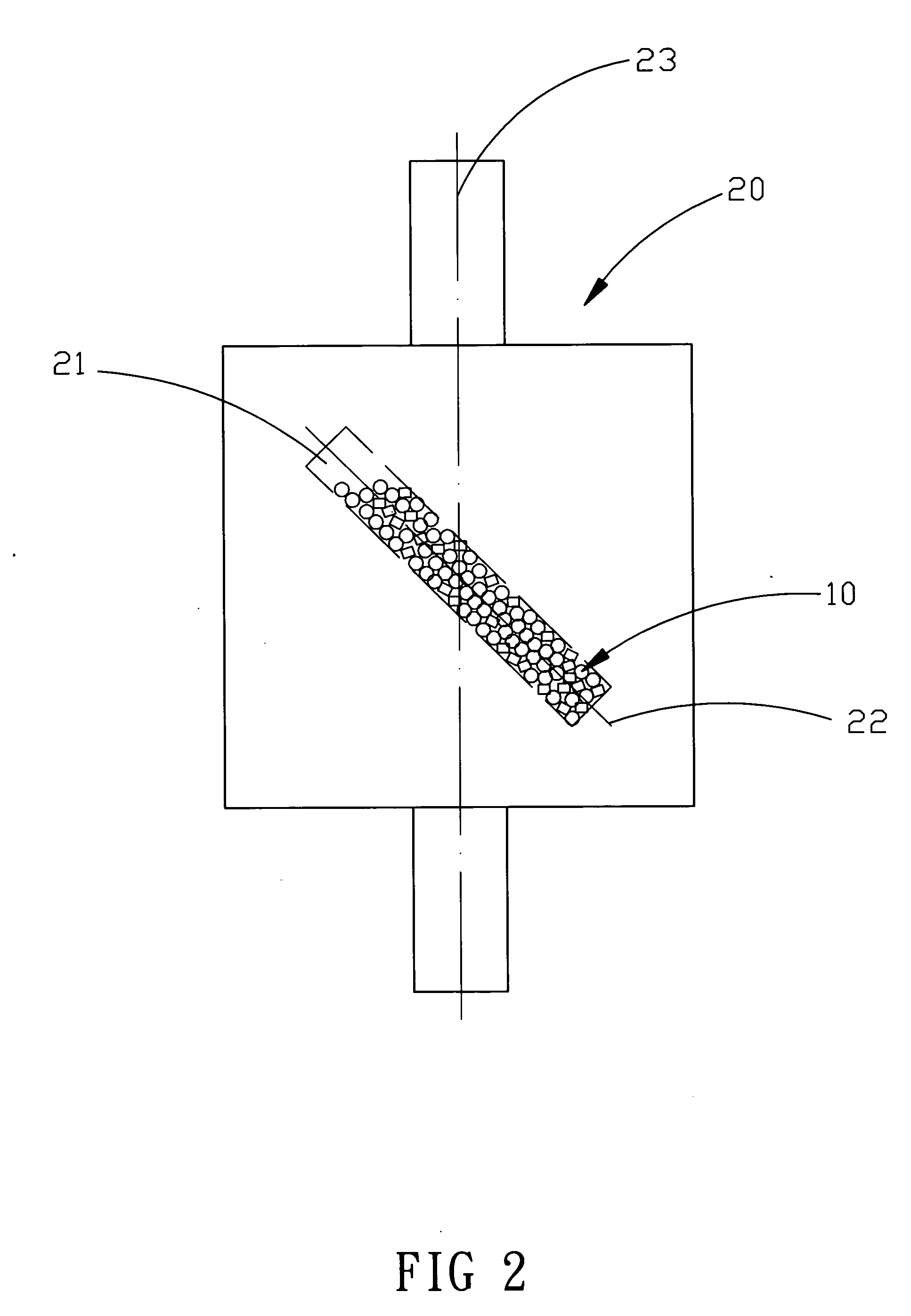

[0019] The particles 10 are filled to 77% to 87% of volume of a cavity 21 in a mold set 20, and an angle 40 to 50 degrees is clamped between an axis 22 of the cavity 21 and a spinning axis 23 to which the mold set 20 is rotated about.

[0020] Step 3: Forming Process

[0021] The mold set 20 is heated up to 140 to 160 degrees Celsius and spun for 22 to 32 minutes as disclosed in FIG. 4.

Step 4: Cooling and Removing the Shoe Sole

[0022] The mold set 20 is cooled and a shoe sole 30 is removed from the cavity 21.

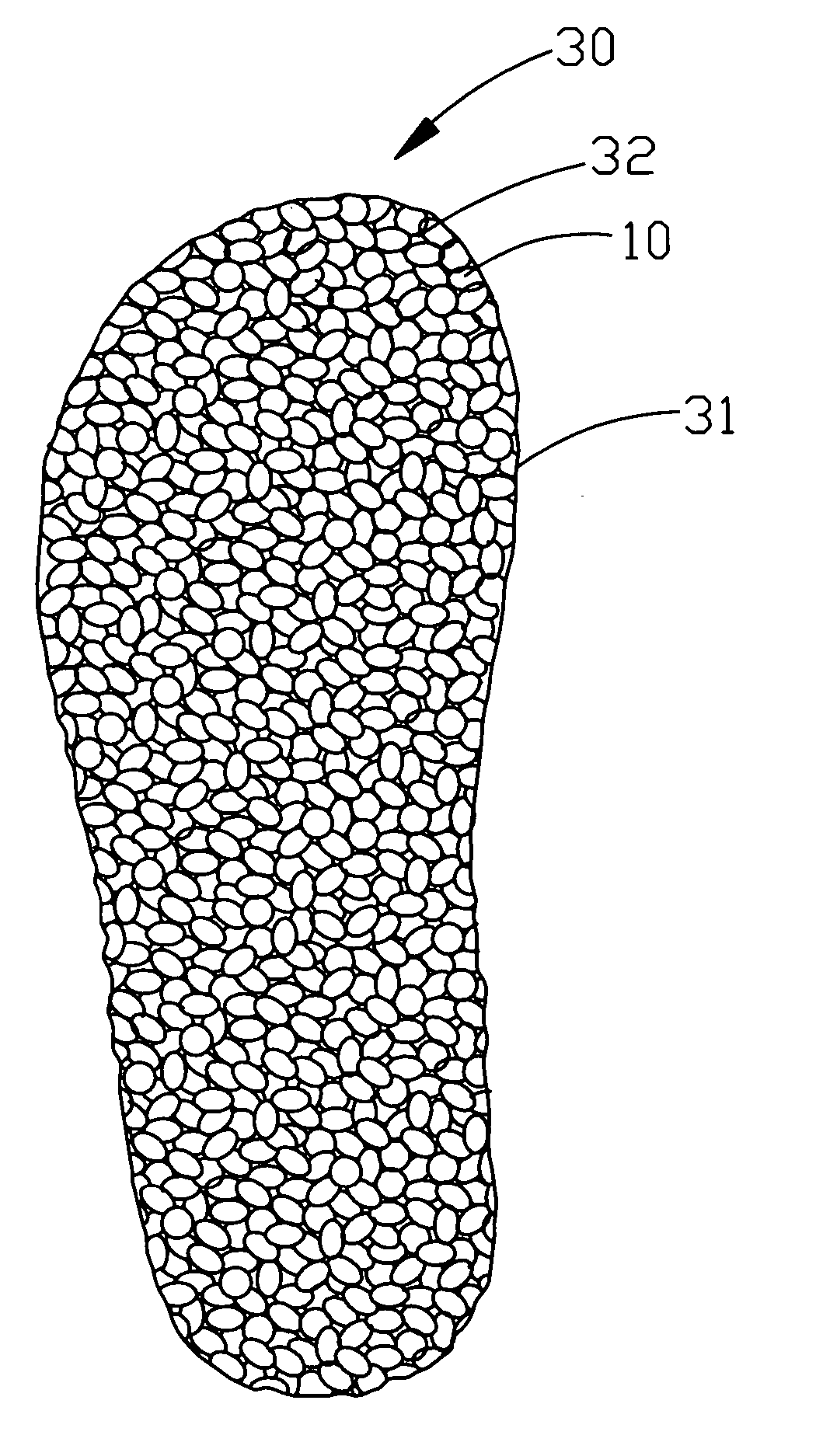

[0023] Referring to FIGS. 3 and 5, the particles 10 are spread and filled in the cavity 21 due to the eccentric force when the mold set 20 spins and the particles 10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com