Method and device for reclaiming residual heat emitted by aluminum electrolysis bath

The technology of an aluminum electrolytic cell and a recovery method, which is applied in the field of waste heat recovery and its device from an aluminum electrolytic cell, can solve the problems of low waste heat utilization rate, energy utilization rate of less than 50%, and high cost, and achieve high waste heat recovery efficiency and structure Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

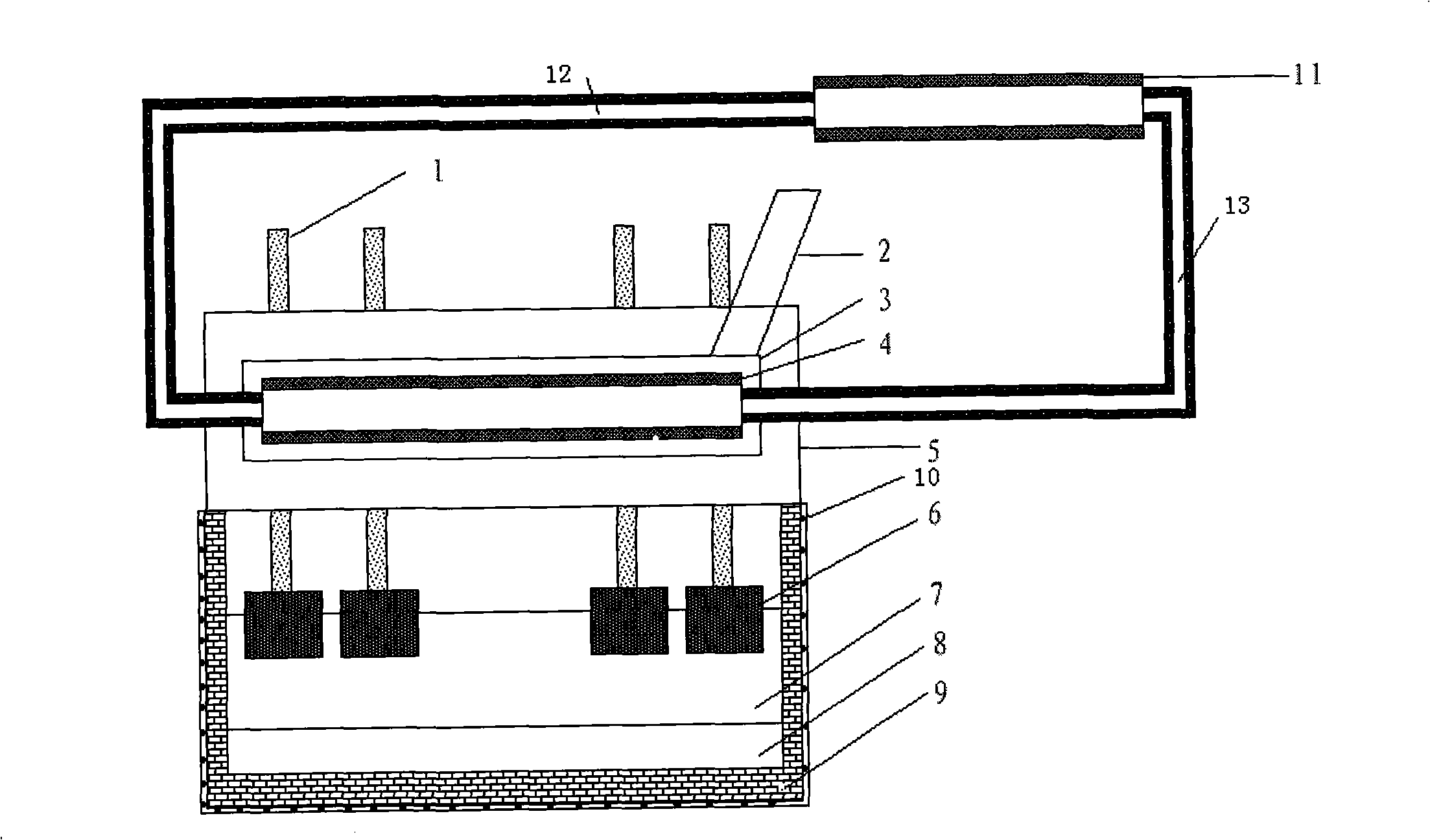

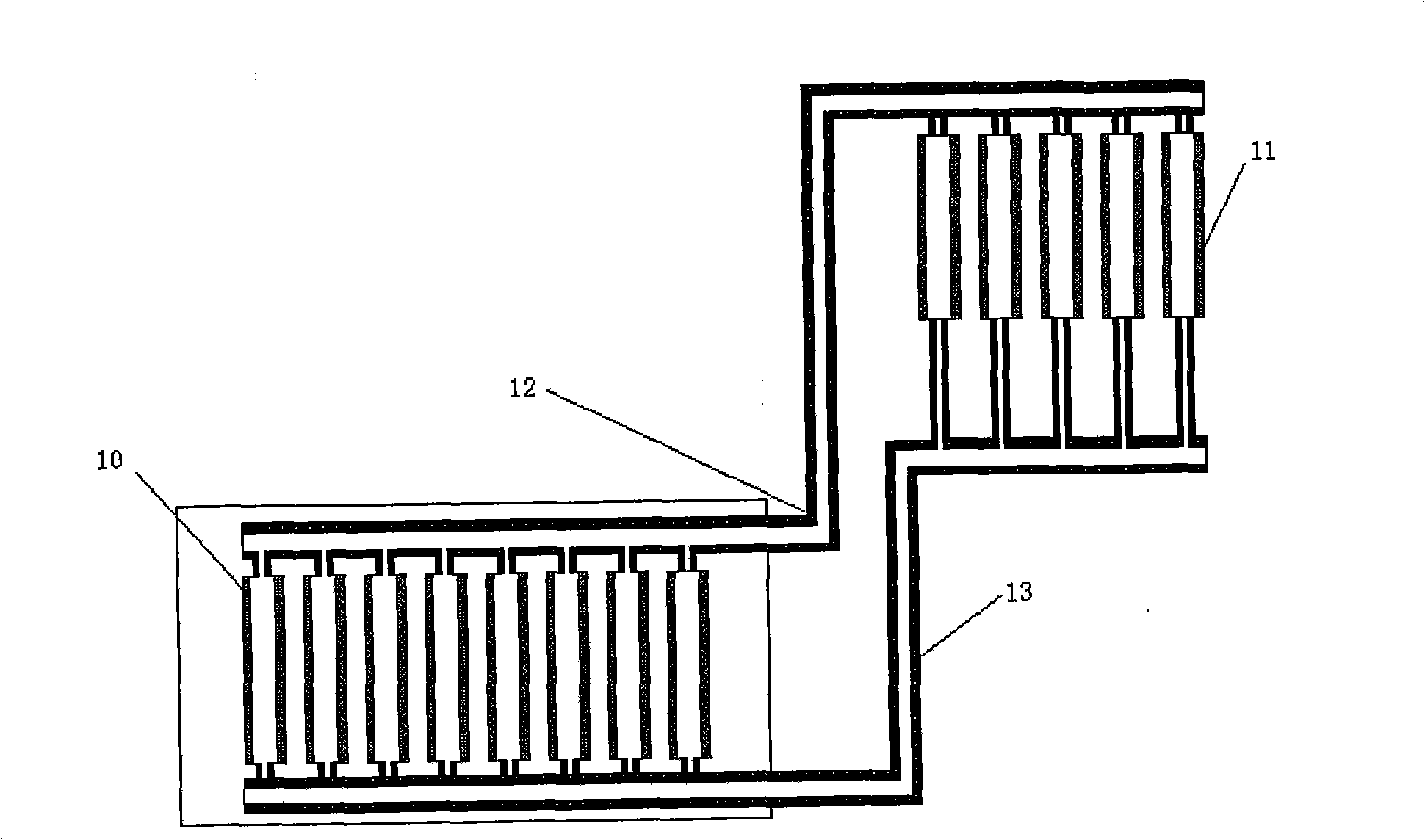

[0019] Example 1: The recovery device for distributing waste heat of the aluminum electrolytic cell of the present invention is as attached figure 1 , figure 2 As shown, a first heat exchange tube with fins is installed in the flue gas channel in the web box on the electrolytic cell, a second heat exchange tube is installed on the side wall of the electrolytic cell, the first heat exchange tube and the second heat exchange tube The outlets of the second heat exchange tubes are respectively connected to the inlets of the tubular condensers of the condensing system through the gas transmission pipelines, and the outlets of the condensers are respectively connected to the inlets of the first heat exchange tubes and the second heat exchange tubes through the return pipes, forming two circulation systems.

[0020] The present invention is implemented on a 300KA electrolyzer, and the heat exchange medium loaded in the first heat exchange tube and the second heat exchange tube is et...

example 2

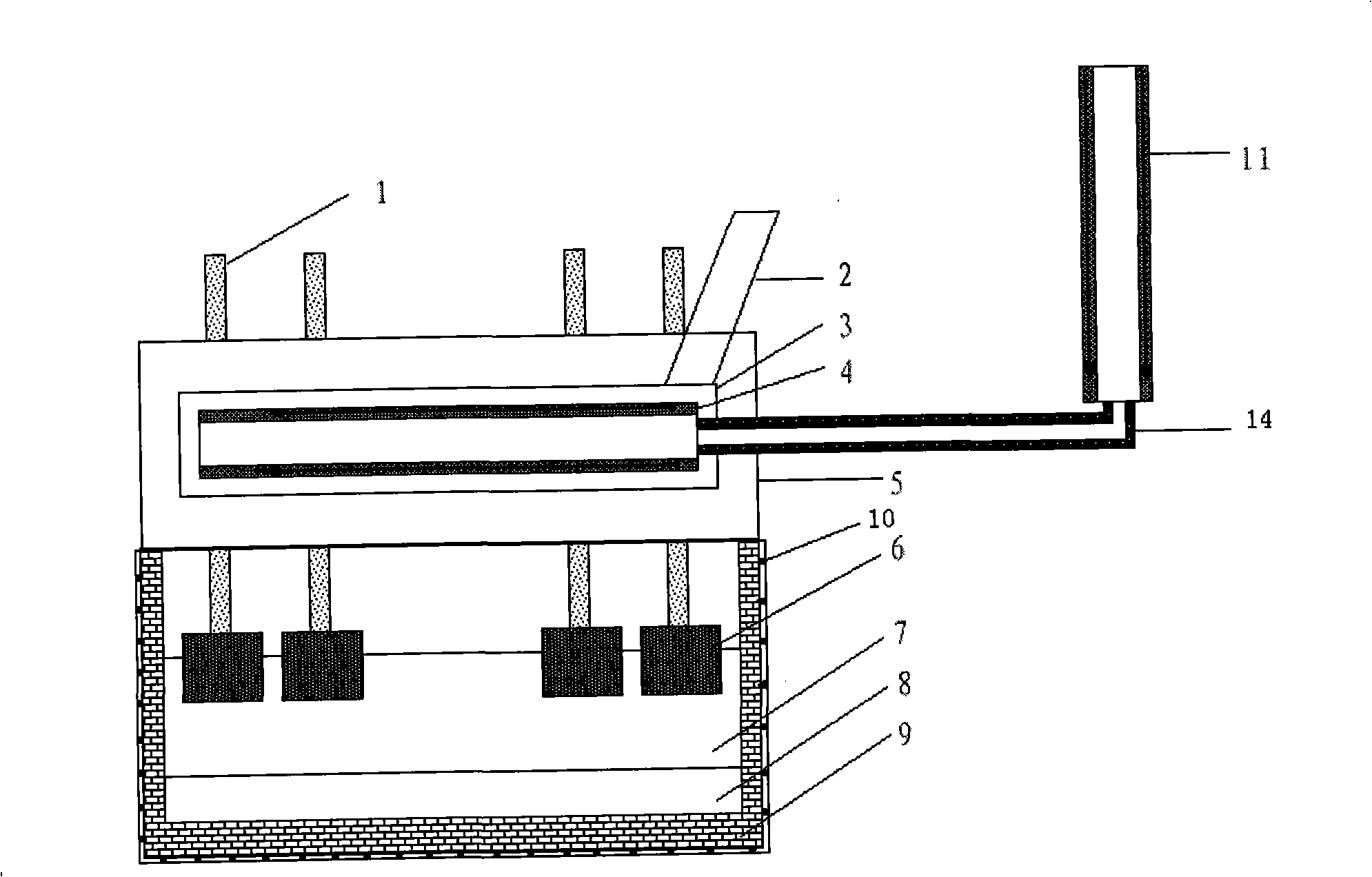

[0021] Example 2: The composition of the device is as follows image 3 , Figure 4 As shown, when the reflux of the heat exchange medium condensate adopts the gross suction method, stainless steel wire mesh is installed in the first heat exchange tube, the second heat exchange tube, the gas pipeline, the return pipeline and the tube wall of the condenser. The gas transmission pipeline and the return pipeline connected between the first heat exchange tube, the second heat exchange tube and the condenser are respectively combined into one gas transmission or return pipeline. The second heat exchange tube is installed on the steel plate on the side wall of the aluminum electrolytic cell.

[0022] The recovery method is the same as Example 1, except that the heat exchange medium is acetone. When the heat exchange medium is heated and vaporized in the first heat exchange tube and the second heat exchange tube, it enters the condenser through the middle of the combined gas transmi...

example 3

[0023] Example 3: The composition of the experimental device used and the recovery method are the same as in Example 2, except that the heat exchange medium is methanol.

[0024] The second heat exchange tube is installed on the steel plate of the side shell of the aluminum electrolytic cell. The recovery of waste heat from the upper part of the electrolytic tank reaches 65%, and the recovery of waste heat from the wall of the electrolytic tank reaches 58%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com