Working process of working fluid and flue gas in supercritical co2 Brayton cycle coal-fired power generation system

A Brayton cycle and power generation system technology, applied in machines/engines, steam engines, mechanical equipment, etc., can solve problems such as reducing power consumption of compressors and affecting the operating characteristics of low-temperature regenerators, reducing friction and pressure drop, The effect of various characteristics with little influence and effective absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

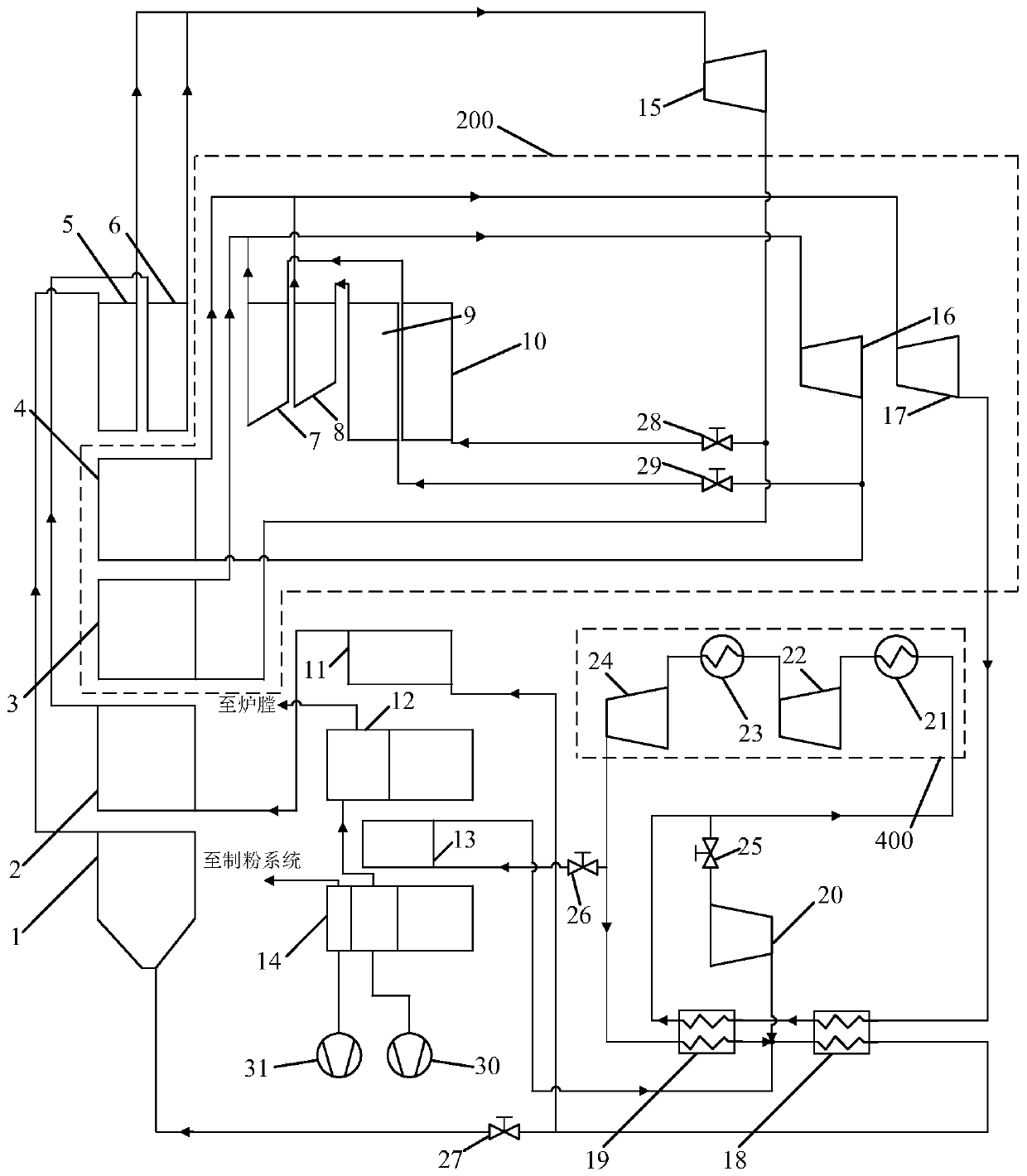

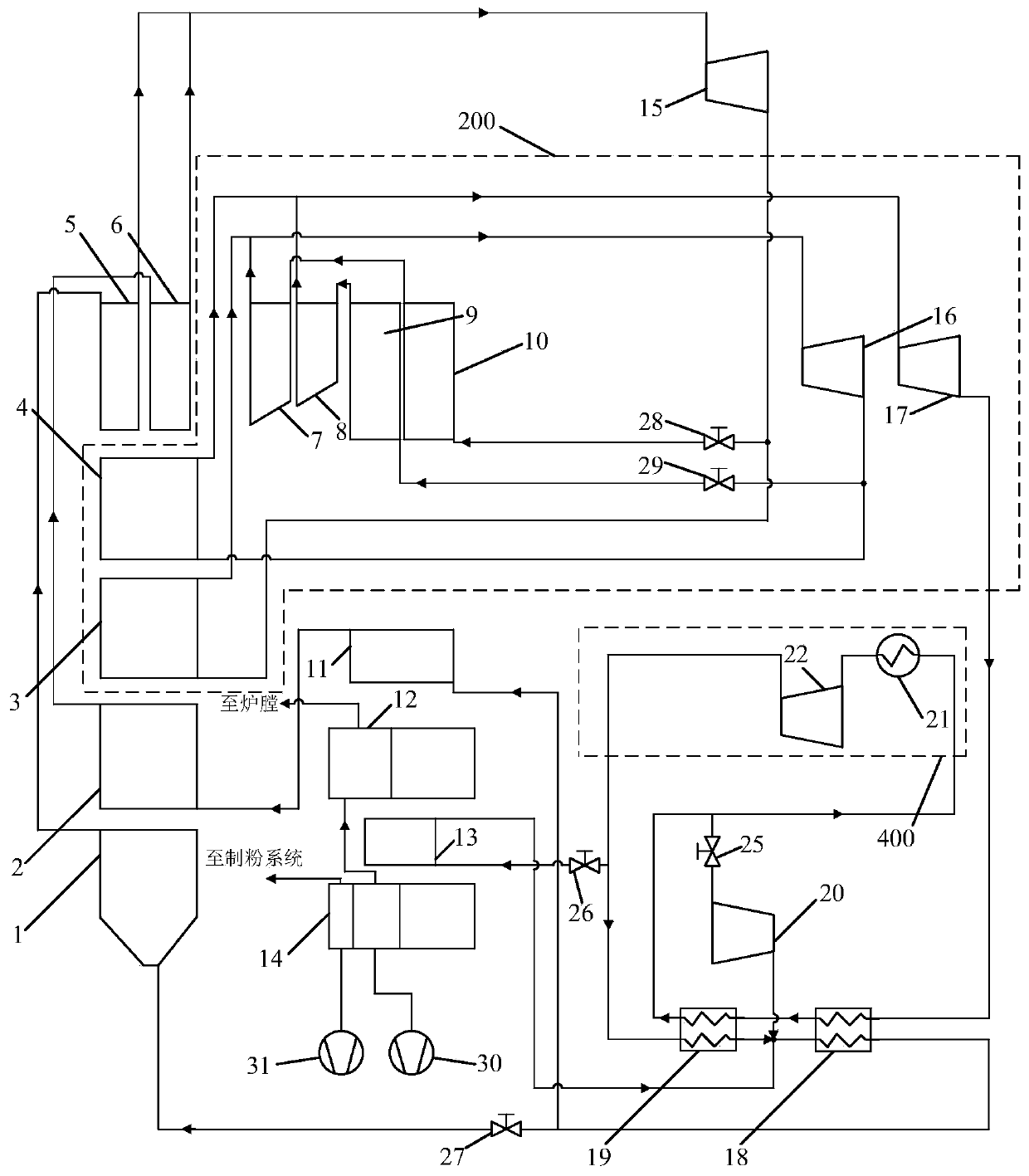

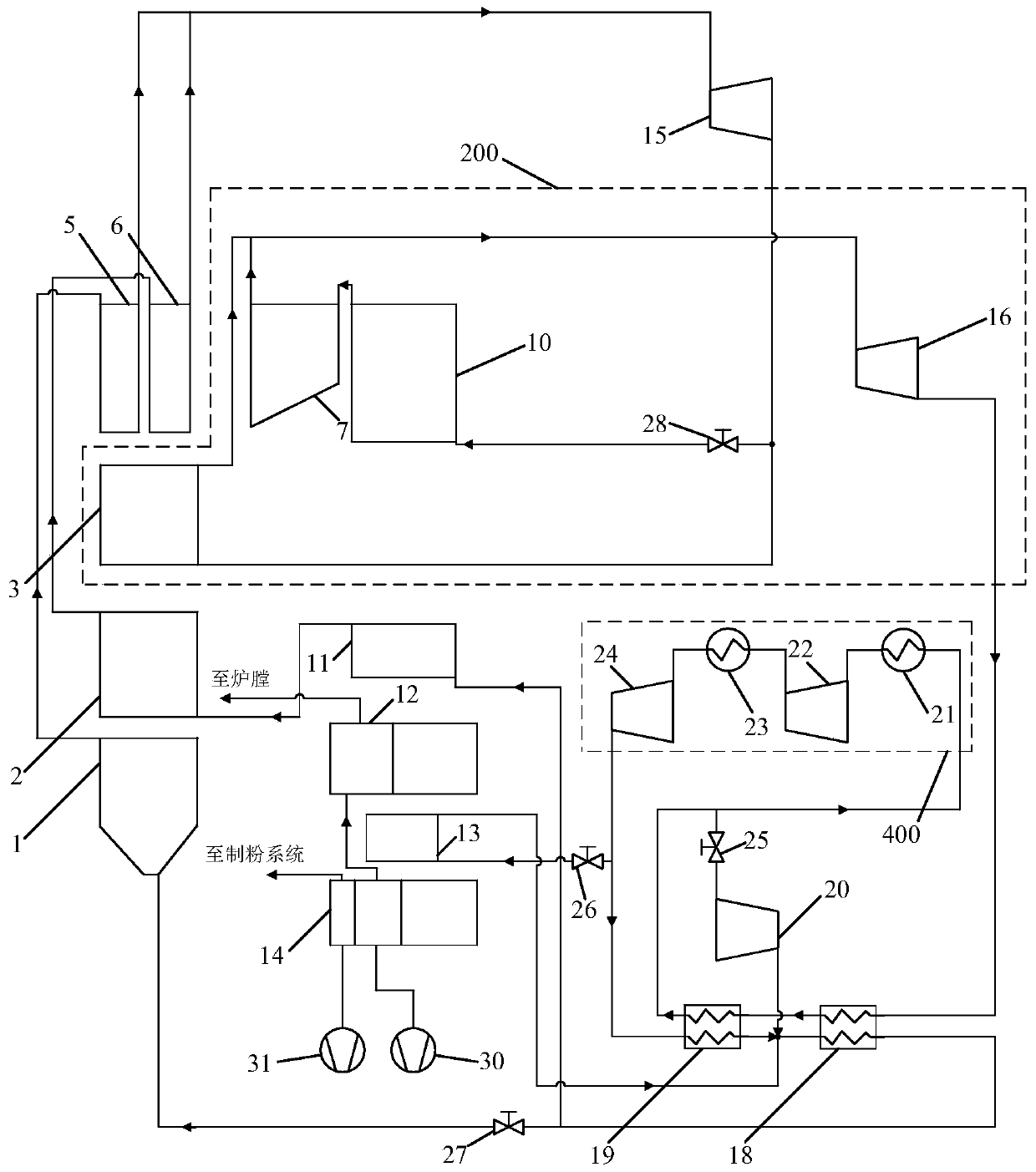

[0031] Further elaborate supercritical CO of the present invention below in conjunction with accompanying drawing 2 Four embodiments of the working fluid and flue gas working process of the Brayton cycle coal-fired power generation system;

[0032] Such as figure 1 The shown embodiment 1 includes: first stave 1, second stave 2, first superheater 5, second superheater 6, economizer 11, second air preheater 12, flue gas cooler 13. First air preheater 14, first turbine 15, high temperature regenerator 18, low temperature regenerator 19, auxiliary compressor 20, cooler 21, auxiliary compressor diverter valve 25, flue gas cooler diverter valve 26. Stave diverter valve 27, air blower 30, primary air blower 31, reheat arrangement system 200 and compression system 400;

[0033] The outlet of the working medium pipeline of the first cooling wall 1 is connected with the inlet of the first superheater 5 working medium pipeline; the outlet of the second cooling wall 2 working medium pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com