Waste heat recovering device of high-temperature metallurgy slag particles

A waste heat recovery device and metallurgical slag technology, which is applied in the field of waste heat recovery in the metallurgical industry, can solve the problems of secondary energy loss, high power consumption, and high investment costs, and achieve the goals of improving output and quality, realizing uniform heat exchange, and ensuring uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

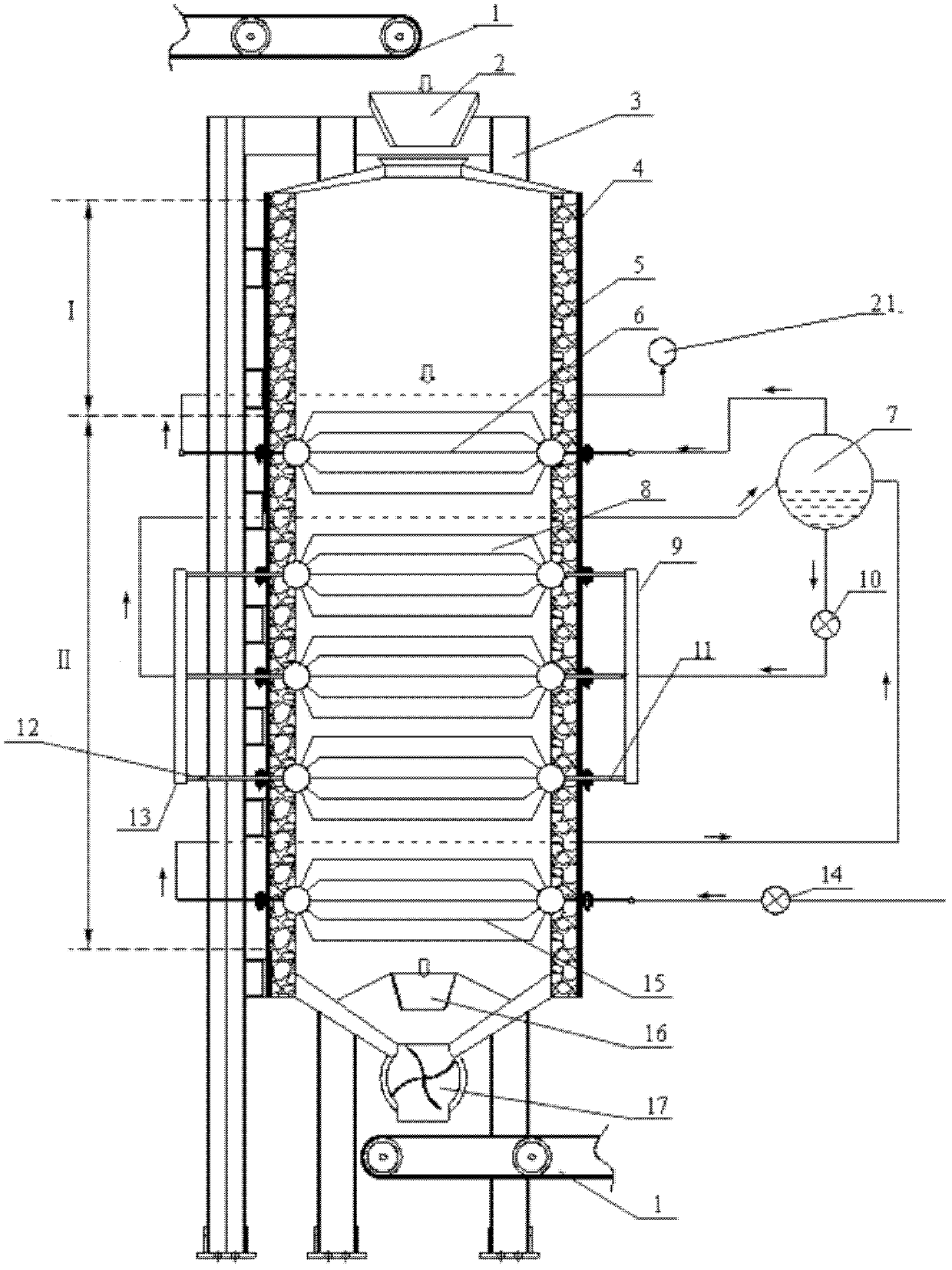

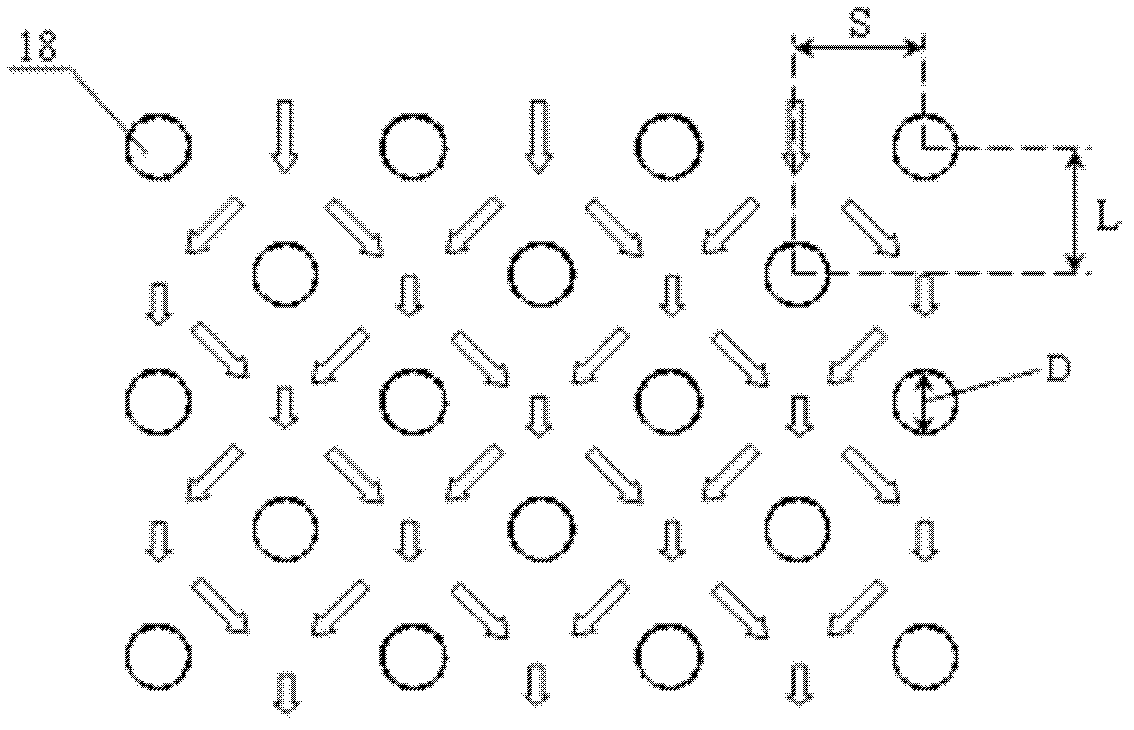

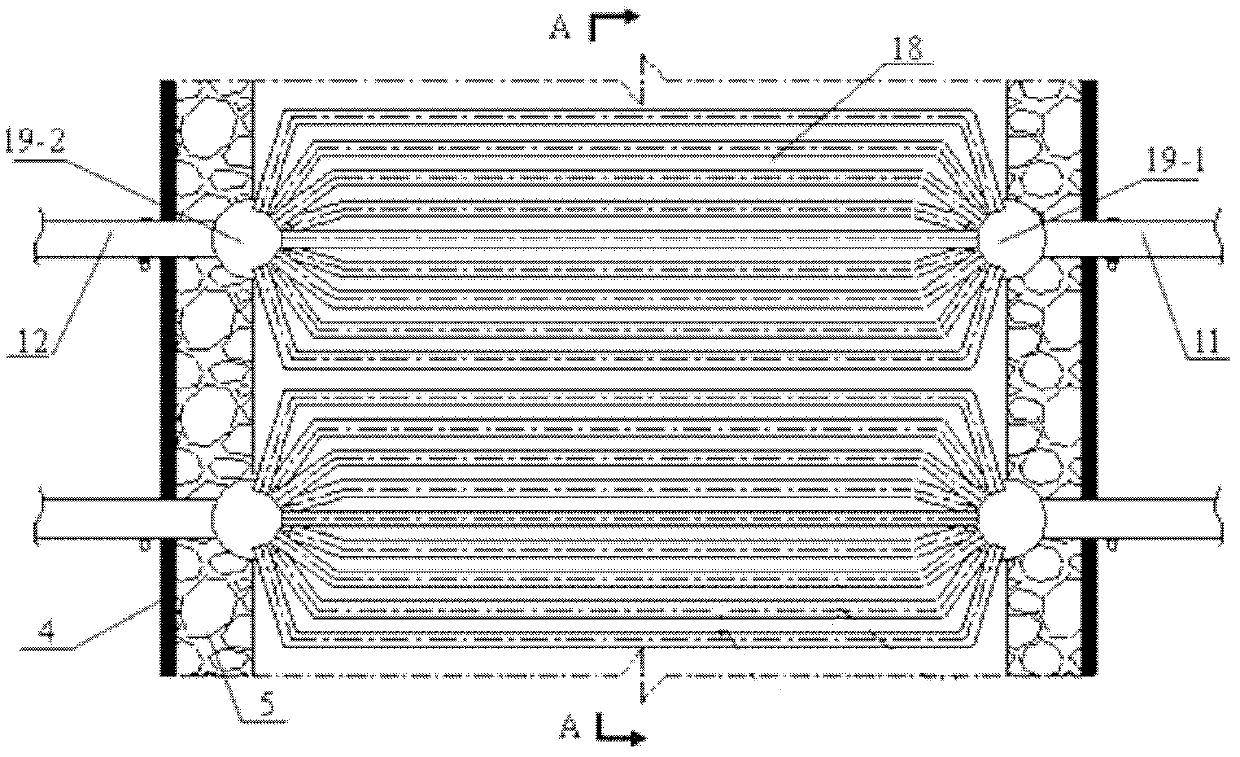

[0021] High-temperature metallurgical slag waste heat recovery device, including intermediate hopper 2, boiler furnace body, steam drum 7, superheater 6, evaporator 8, economizer 15 and discharger 17, the intermediate hopper 2 is set at the inlet of the boiler furnace body Above, the boiler furnace body is a rectangular furnace shell 4 welded by stainless steel plates. The built-in refractory material 5 forms a rectangular cavity and is fixed on the boiler bracket 3. The boiler furnace body is divided into storage section I and working section II from top to bottom. The height of the storage section I is 1 / 4~1 / 2 of the height of the working section II, and the superheater 6, the evaporator 8, and the economizer 15 are sequentially arranged in the working section II from top to bottom, and a superheater is provided in this embodiment 6. Three evaporators...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com