Efficient waste heat recycling comprehensive utilizing system

A waste heat recovery and high-efficiency technology, applied in the field of waste heat recovery, can solve the problems of providing a comfortable working environment for unoperable workers and difficult conditions, and achieve the effects of comprehensive functions, fuel saving, and high waste heat recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

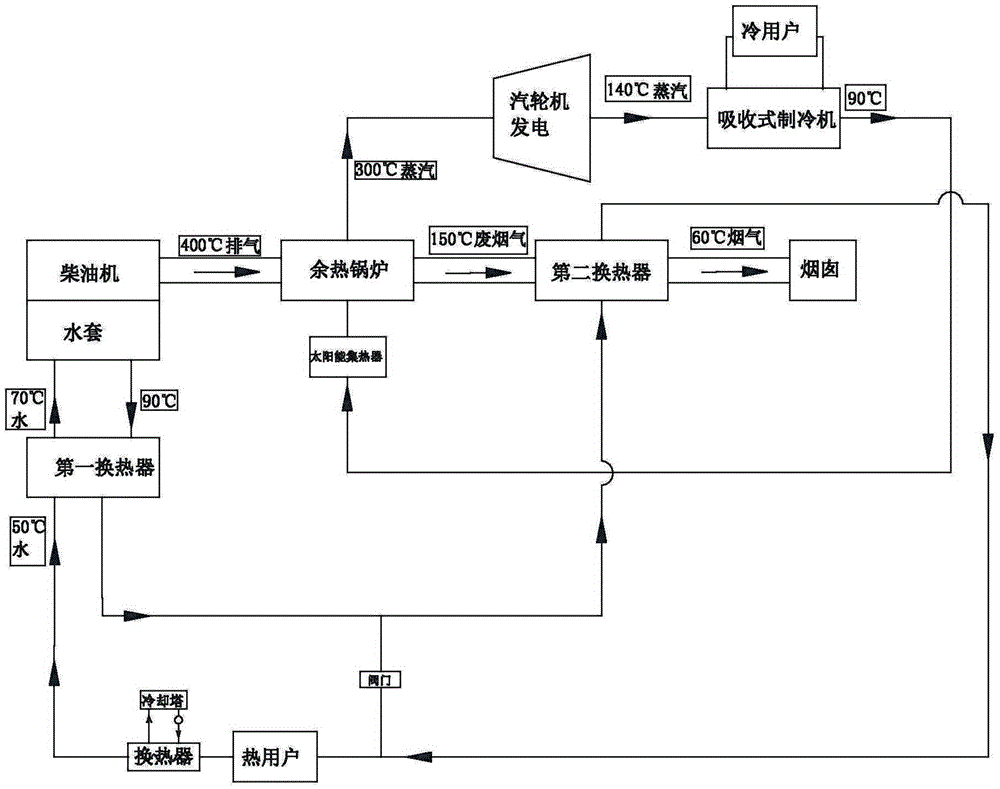

[0023] A high-efficiency waste heat recovery comprehensive utilization system, such as figure 1 As shown, it can be used for exhaust gas and cooling water waste heat recovery of diesel engines or gas engines, which includes tail gas waste heat recovery subsystems, cooling water waste heat utilization subsystems and power generation cooling subsystems. The tail gas waste heat recovery subsystem includes a waste heat boiler and a second heat exchanger, and the waste heat boiler is connected to the exhaust gas pipe for introducing the flue gas into the waste heat boiler to absorb high-temperature heat in the exhaust gas of the diesel engine or gas engine, Reduce the flue gas temperature as high as 400°C to 150°C, which can reduce environmental pollution. The waste heat boiler absorbs exhaust gas heat with a temperature as high as 400°C; the outlet end of the waste heat boiler is connected to a second heat exchanger through a flue, and the flue gas outlet of the second heat exchan...

Embodiment 2

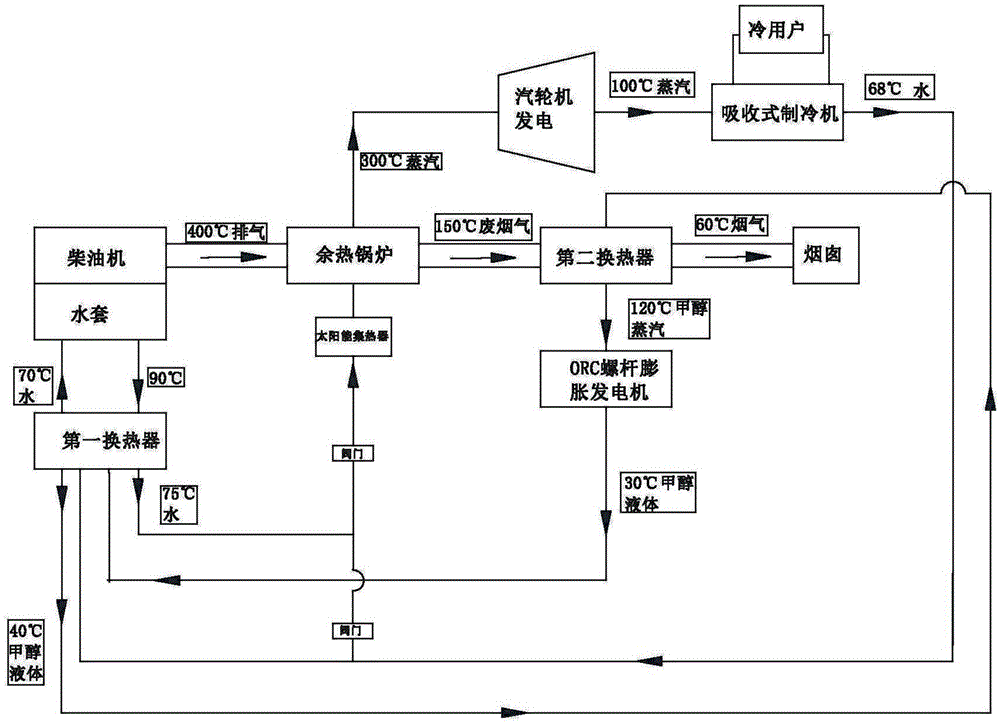

[0026] A high-efficiency waste heat recovery comprehensive utilization system, such as figure 2 As shown, it can be used for diesel engine and gas engine tail gas and cooling water waste heat recovery and utilization, which includes tail gas waste heat recovery subsystem, cooling water waste heat utilization subsystem and power generation cooling subsystem; the cooling water waste heat utilization subsystem includes water jacket Connect the first heat exchanger for heat exchange, waste heat boiler, turbo generator and absorption refrigerator, the first heat exchanger is connected with the waste heat boiler through the delivery pipe, and the waste heat boiler is connected with the steam turbine through the delivery pipe The generator is connected, the turbogenerator is connected to the absorption refrigerator through the delivery pipe, and the absorption refrigerator is connected to the first heat exchanger through the delivery pipe to form a cooling water waste heat utilizatio...

Embodiment 3

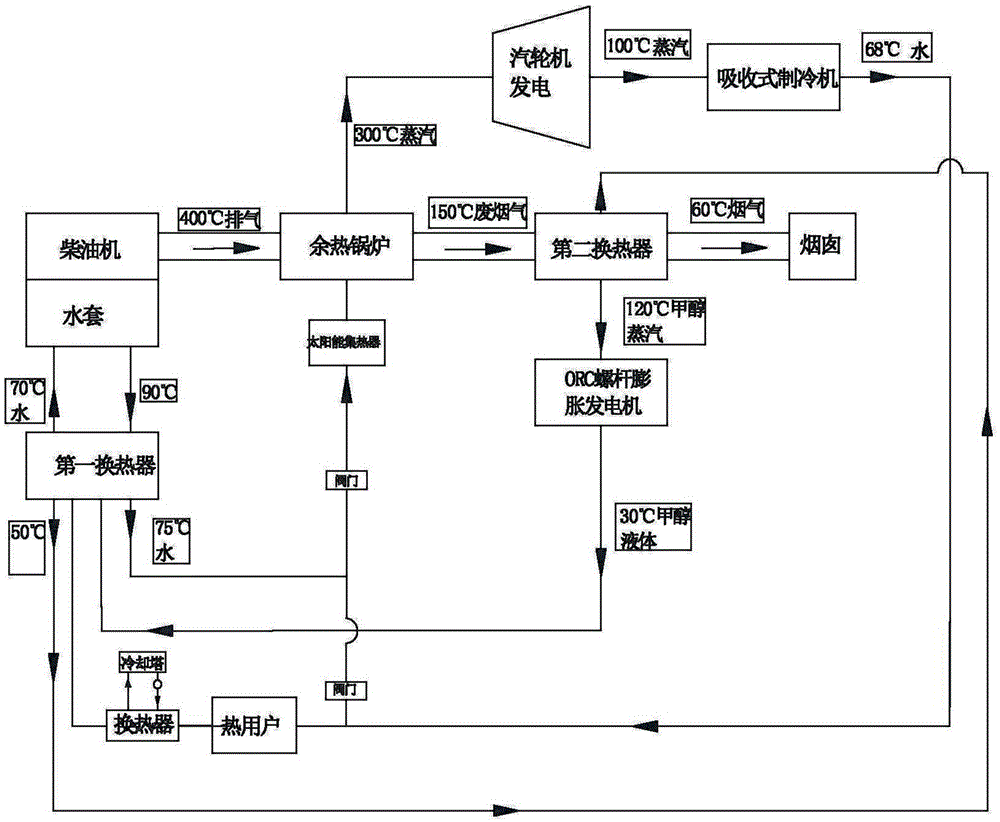

[0030] A high-efficiency waste heat recovery comprehensive utilization system, such as image 3As shown, it can be used for recovery and utilization of diesel engine exhaust and cooling water waste heat, including tail gas waste heat recovery subsystem, cooling water waste heat utilization subsystem and power generation cooling subsystem, etc. The cooling water waste heat utilization subsystem includes a first heat exchanger connected to the water jacket for heat exchange, a waste heat boiler and a steam turbine generator. The first heat exchanger is connected to the waste heat boiler through pipelines, and then connected to the steam turbine generator to generate electricity , the turbogenerator is connected to the absorption refrigerating machine, and the absorption refrigerating machine can be connected to the first heat exchanger through the heat user and the third heat exchanger to form a cooling water waste heat utilization subsystem circulation loop. The third heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com