Cascade waste heat recovery device and method utilizing pyrolysis gasification of solid particle heat carrier

A waste heat recovery device and a technology for solid particles, which are applied in gasification process, chemical industry, climate sustainability, etc., can solve the problems of low recovery efficiency and difficult recovery of waste heat from high-temperature solid particles, so as to save resources, protect the environment, reduce Effects of Greenhouse Gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] The slag used in the implementation of the present invention is derived from the slag discharge of a domestic iron and steel enterprise blast furnace, and the main components are shown in Table 5.

[0124] Table 5 Chemical composition of slag particles%

[0125]

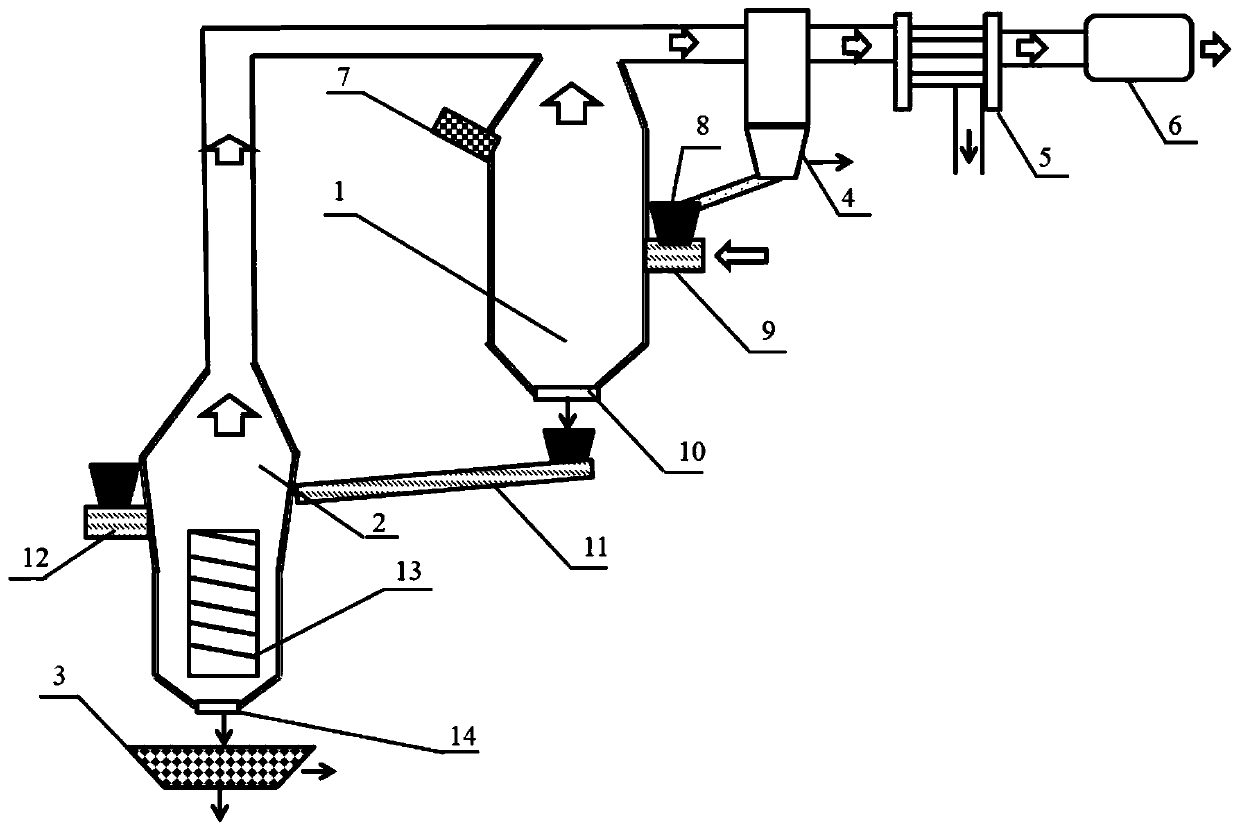

[0126] The structure diagram of the cascade waste heat recovery device using solid particle heat carrier pyrolysis and gasification is as follows figure 2 As shown, including gasification furnace 1, pyrolysis furnace 2, solid separator 3 and its auxiliary equipment, pyrolysis furnace 2, gasification furnace 1 is mainly composed of a furnace body, a feeding device system and a flue gas processing device system. The feeding device system is equipped with high particle feeding device 7, medium and low temperature particle feeding device 11, gasifier fuel nozzle 9, pyrolysis furnace fuel nozzle 12, gasifier particle outlet 10, pyrolysis furnace particle outlet 14; flue gas The treatment system is provided with a cyclo...

Embodiment 2

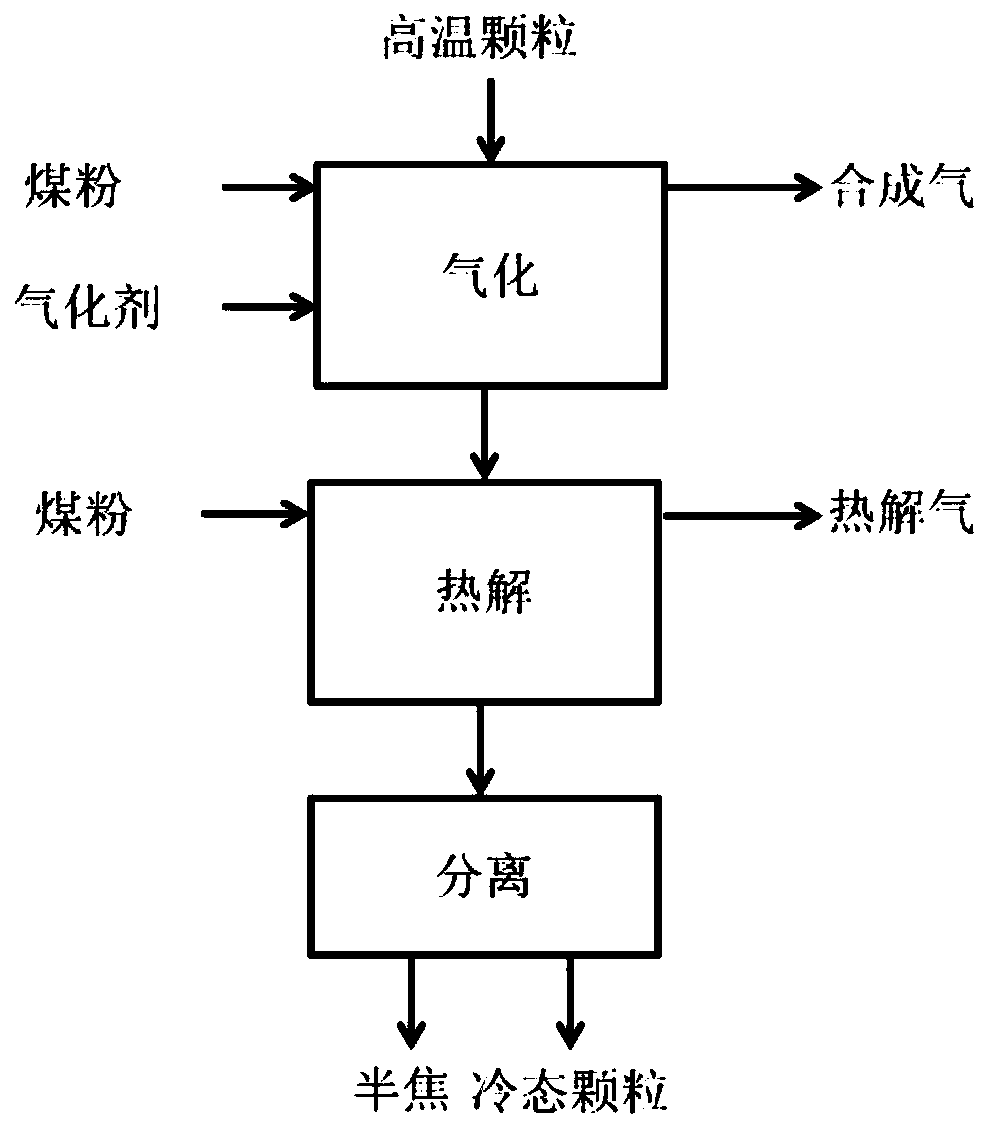

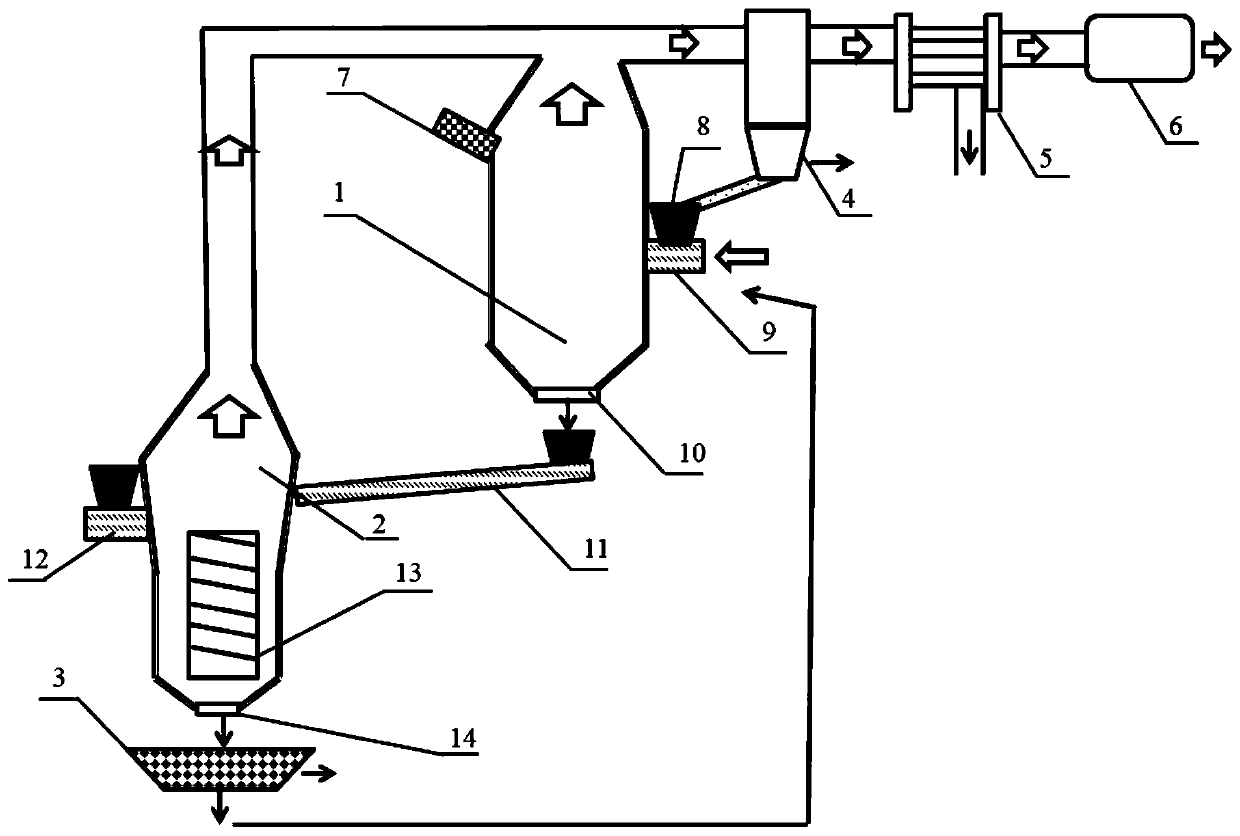

[0141] The structure diagram of the cascade waste heat recovery device using solid particle heat carrier pyrolysis and gasification is as follows Figure 4 As shown, the method for cascaded waste heat recovery using the above device, the process flow chart is as follows image 3 Shown.

[0142] Compared with Example 1, the difference lies in:

[0143] (1) In terms of process method, the fuel in the gasification furnace 1 in Example 2 is semi-coke produced in the pyrolysis furnace 2. In terms of device structure, the outlet material of the solid separator 3 enters the gasification furnace fuel nozzle 9 through a lifting device.

[0144] (2) The products in the gasifier 1 in Example 2 are combustible gas and porous coke, and the specific surface area of the porous coke is 1100m 2 / g above. The combustible gas passes through the cyclone separator, gas-liquid separator and purifier to remove volatiles and condensable tar to obtain clean gas. The yield of clean gas is 30%, and the calor...

Embodiment 3

[0151] Same as Example 1, the difference lies in:

[0152] (1) The high-temperature particles in Example 3 are steel slag, the temperature of the steel slag is 1200°C, and the main components are shown in Table 6.

[0153] Table 6 Chemical composition of steel slag particles%

[0154]

[0155] (2) In Example 3, the clean gas production rate is 33%, and the clean gas heating value is about 6000kJ / m 3 ;

[0156] (4) In Example 3, the gasification agent is a certain furnace flue gas, and the composition and content are CO 2 30.8%, N 2 60.1%, O 2 0.6%, CO 3.2%, H 2 O 5%, SO 2 0.26%, other 0.04%.

[0157] (5) In Example 3, CO in the flue gas in the gasifier 1 2 The molar ratio of element C to coal powder is CO 2 / C 1:1. The ratio of the mass of high-temperature particles to the mass of pulverized coal C element is 1:0.05, and the temperature of the particles after a cooling is 800℃.

[0158] In the pyrolysis furnace, the ratio of the particle mass to the C element mass in the pulverized c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com