Gradient waste heat recovery and direct reduction system and method for iron-containing metallurgical slag particles

A waste heat recovery system and waste heat recovery technology, applied in the direction of improving process efficiency and reducing gas emissions, can solve the problems of low waste heat recovery efficiency and poor economy of metallurgical slag particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0147] The slag used in the implementation of the present invention comes from the slag discharge of a flash smelting furnace of a domestic copper smelting enterprise, and its main components are as shown in Table 1.

[0148] Method A:

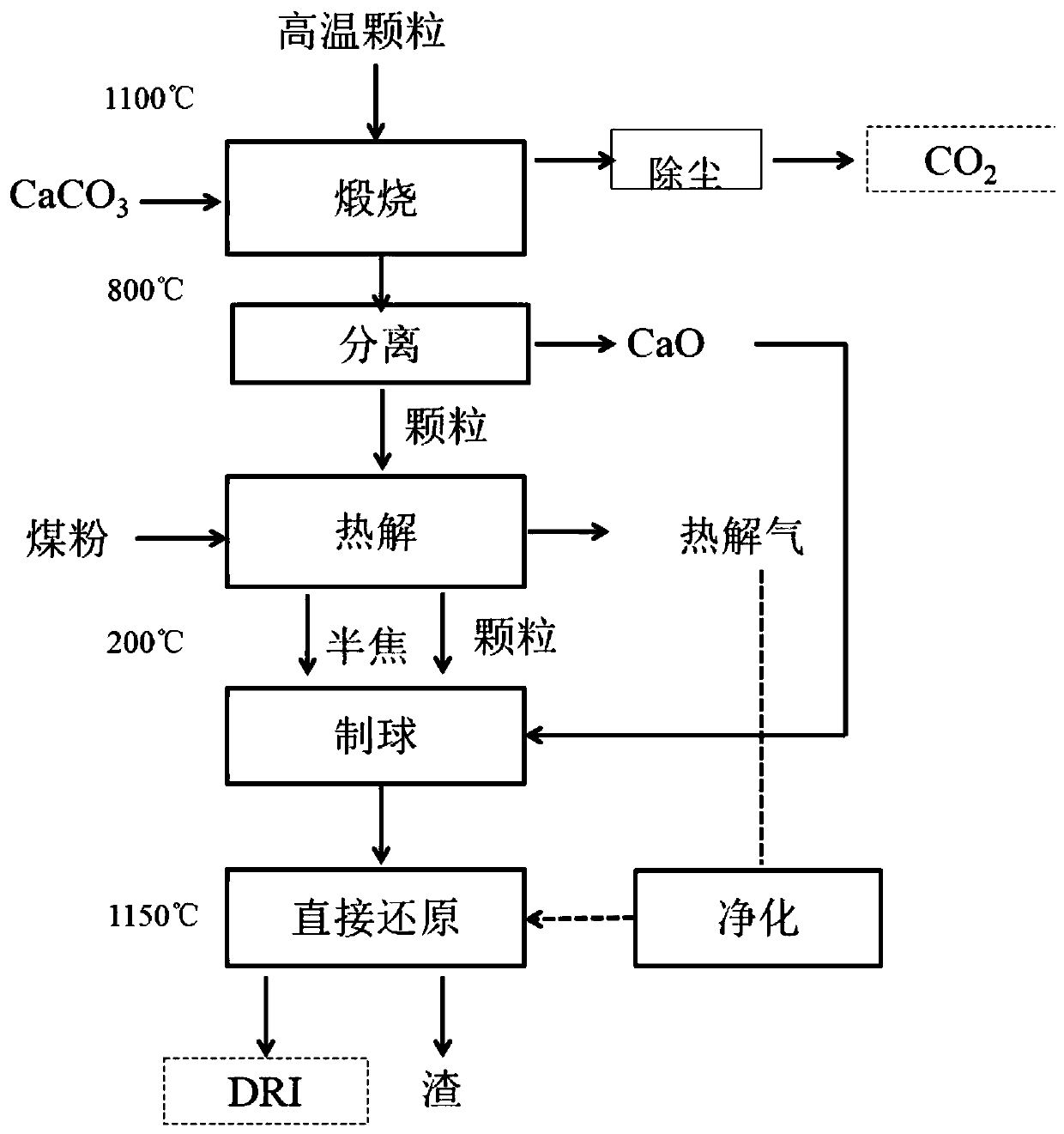

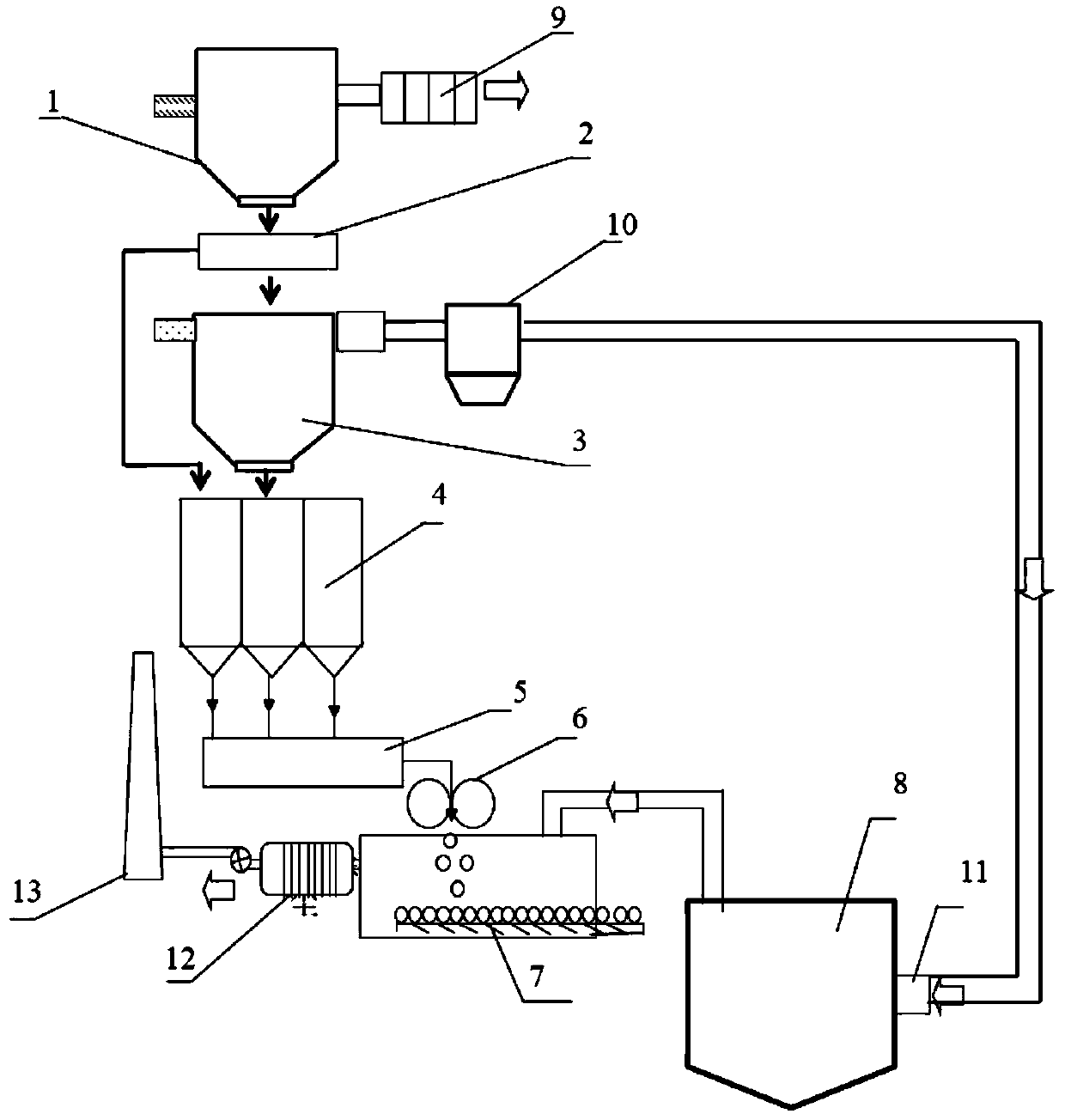

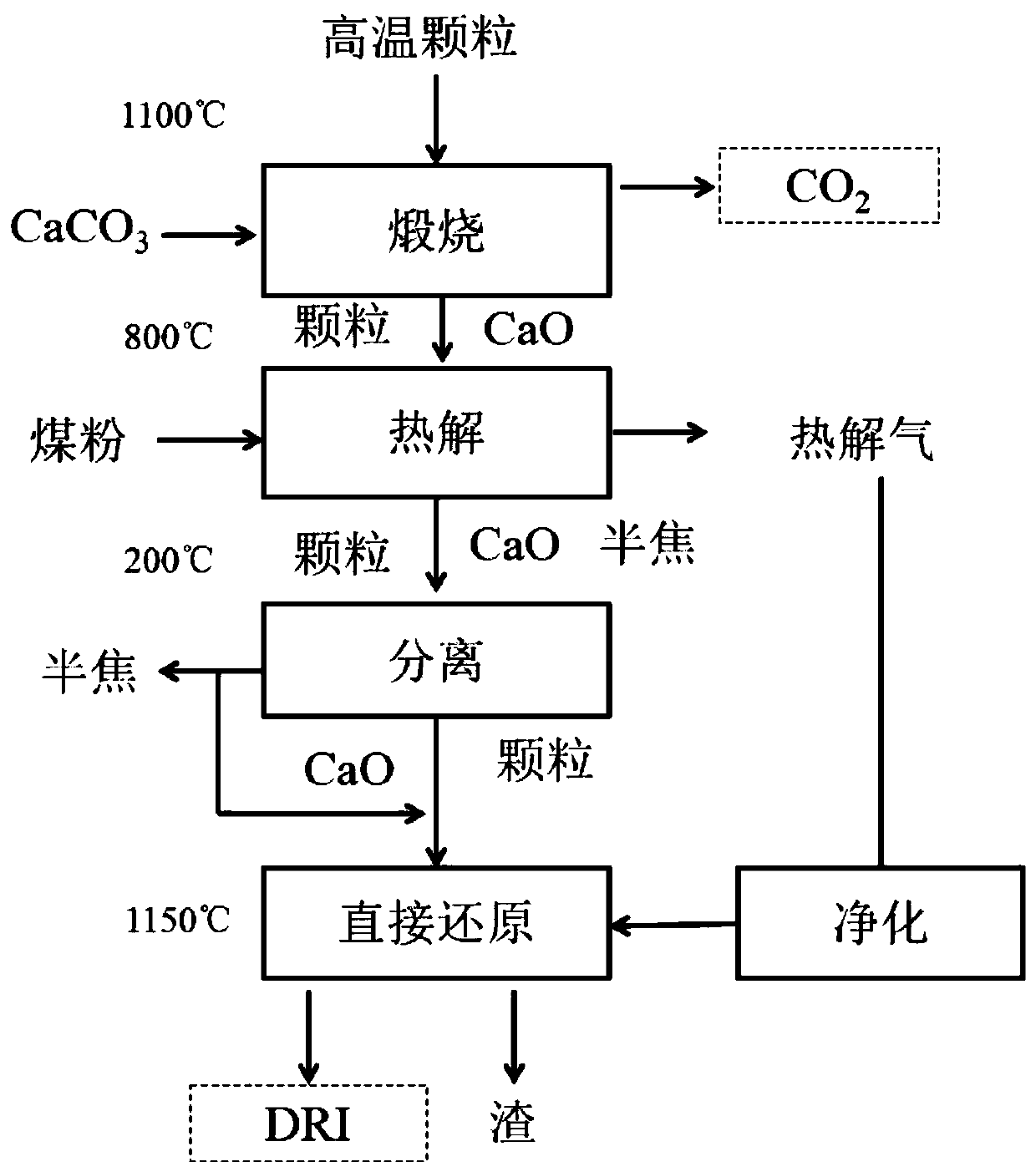

[0149] A method for cascaded waste heat recovery and direct reduction of iron-containing metallurgical slag, the process flow chart of mode A is as follows figure 1 As shown, the process mainly consists of four steps: calcination, pyrolysis, pelletizing and direct reduction. The main raw materials of the calciner are limestone, CaCO 3 The content is 92%. The main raw material of the pyrolysis furnace is pulverized coal, and the type is lignite. The industrial analysis is shown in Table 2. The calciner and pyrolysis furnace are both fixed beds. In the two devices, limestone and coal powder need to be dried and ground to below 100 mesh before entering. The products of the pyrolysis furnace are pyrolysis gas and semi-coke. The components of t...

Embodiment 2

[0185] Method A:

[0186] A cascade waste heat recovery and direct reduction system for iron-containing metallurgical slag particles, adopting mode A, and the system structure is the same as that of embodiment 1 mode A, and the method for cascade waste heat recovery and direct reduction of ferrous metallurgical slag particles using this system is the same as in embodiment 1 Mode A, compared with Embodiment 1, its difference lies in:

[0187] (1) The iron-containing metallurgical slag used in Example 2 comes from the slag discharge of a domestic nickel smelting enterprise, and the high-temperature particles are granulated nickel slag particles. The main components of nickel slag particles are shown in Table 7.

[0188] (2) The main raw material of the pyrolysis furnace in Example 2 is coal powder, and the industrial analysis is shown in Table 8.

[0189] (3) The direct reduction furnace in embodiment 2 is a rotary hearth furnace.

[0190] Table 7 Chemical composition of nick...

Embodiment 3

[0221] Method A:

[0222] Compared with embodiment 1, its difference is:

[0223] (1) The carbon-containing solid waste adopted in Example 3 is biomass, and the type of biomass is pine chips, and its component analysis is shown in Table 13.

[0224] Table 13 Biomass composition analysis

[0225]

[0226] Table 14 Composition of clean gas obtained after pyrolysis gas separation under mode A, %

[0227]

[0228] Table 15 Industrial analysis of solid semi-coke under mode A, %

[0229]

[0230] The process system and method for recovering waste heat from high-temperature particles using the above-mentioned device, the specific steps are as follows:

[0231] (1) Waste heat recovery in the high temperature section of copper slag particles

[0232] Copper slag particles (with a particle size range of 0.5-2 mm) and limestone (100 mesh) at 1100° C. enter the calciner 1 through the feeding device 7 . The temperature inside the calciner 1 is 600-1000°C, and the mass ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com