ORC (organic Rankine cycle) system for marine main engine waste heat generation

A ship main engine and thermal power generation technology, which is applied to machines, machines/engines, and mechanical equipment that use waste heat, can solve problems such as energy loss, system complexity, performance matching, and system control difficulties, and achieve high-temperature cracking and modification of refrigerants. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

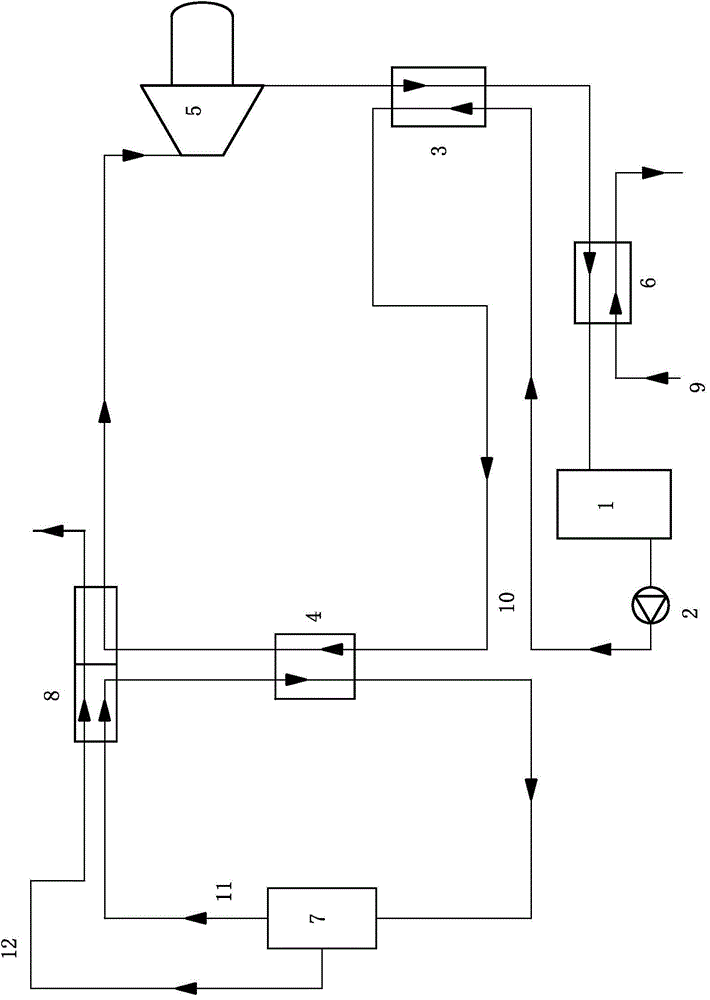

[0015] With reference to the accompanying drawings, an ORC system for waste heat power generation of a main engine of a ship according to the present invention includes an engine exhaust circuit, an engine jacket water circuit, a refrigerant circuit and an external cooling water circuit.

[0016] In the engine exhaust circuit, the engine exhaust passes through the flue gas heat exchanger 8 to dissipate heat before being directly discharged into the environment, and then transfers the heat to the cylinder jacket water and the refrigerant in turn, thereby realizing the recovery of exhaust heat. The flue gas heat exchanger in this system is a two-stage flue gas heat exchanger. The first stage is the heat exchange between the engine flue gas and the cylinder jacket water of the engine, and it is arranged downstream; the second stage is the heat exchange between the engine flue gas and the ORC system refrigerant. Heat exchange is also arranged along the flow. In actual operation, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com