A cross-flow coal blending pyrolysis method and pyrolysis device

A technology of pyrolysis and coal blending, which is applied in the field of coal chemical industry, can solve the problems of uneven gas-solid heat transfer, easy blockage of equipment pipelines, and low processing capacity of a single furnace, so as to improve product quality, compact structure, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

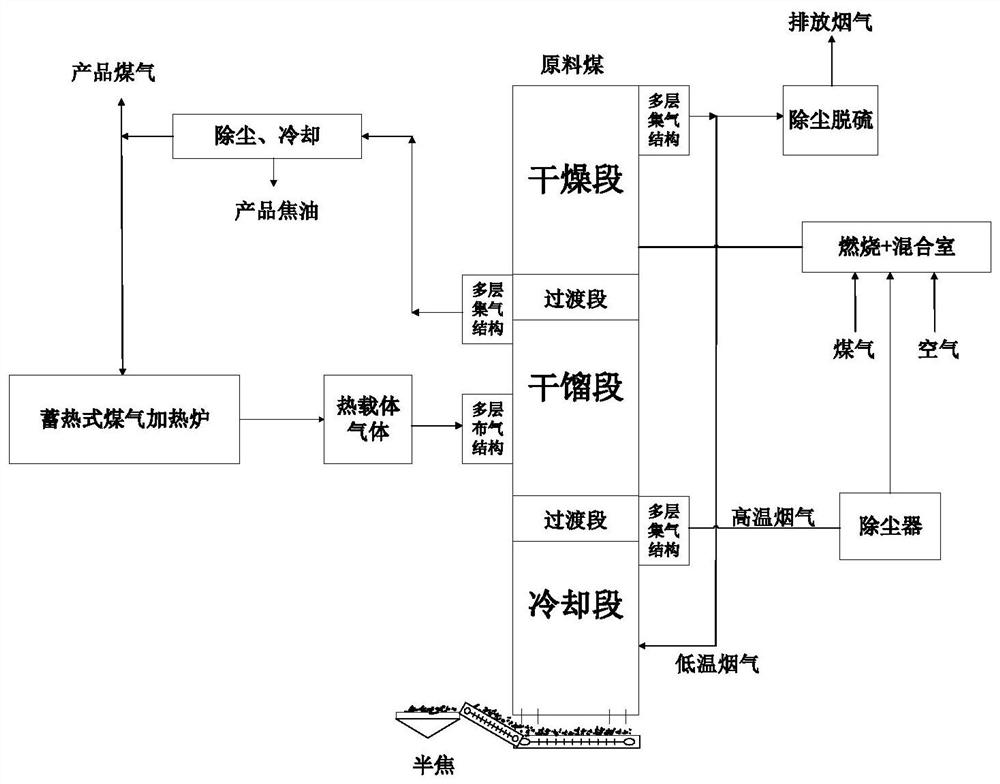

[0039] This embodiment takes long-flame coal pyrolysis as an example, as figure 1 As shown, the raw material can be directly fed into the furnace through the conveyor belt, and exchange heat with the hot flue gas in the drying section. The external water is completely removed, and the temperature of the material rises to about 200°C. Under the action of gravity, the material enters the dry distillation section and exchanges heat with 850°C gas. In order to reduce the resistance of the gas passing through the material and increase the gas residence time, the high-temperature gas is introduced into the furnace through a multi-layer air intake structure. The temperature of the material is gradually increased to 600°C and a pyrolysis reaction occurs, and the volatile matter is precipitated in the form of a gas. Then it is assembled by the multi-layer gas-collecting structure in the furnace and then exported to the outside of the furnace. The temperature of the gas outlet is about ...

Embodiment 2

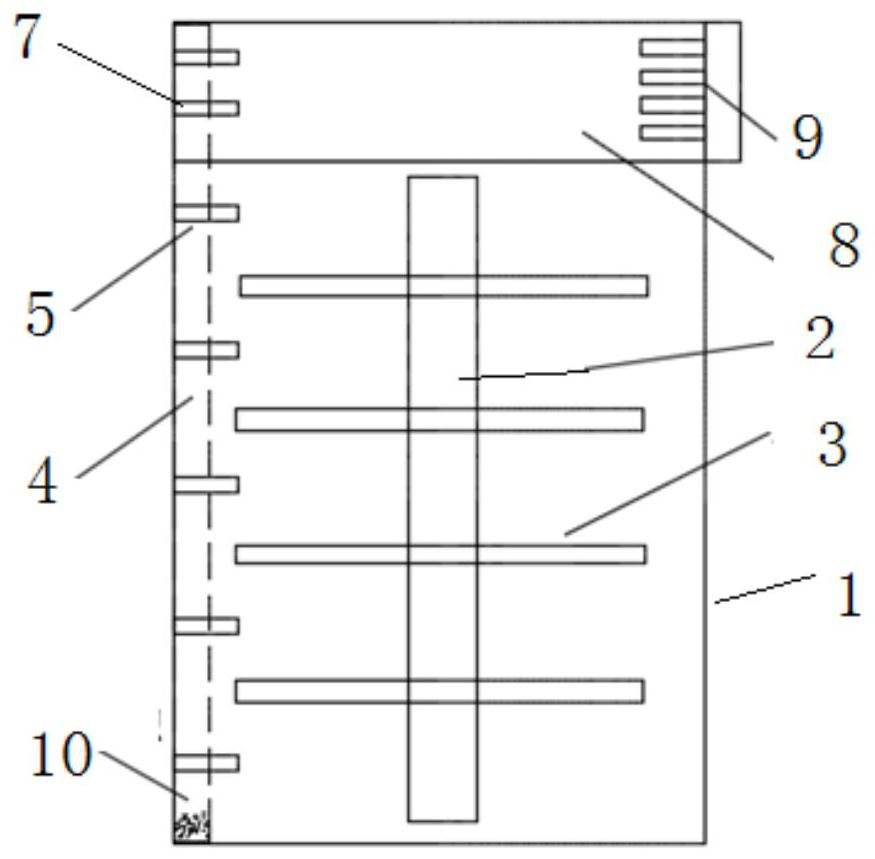

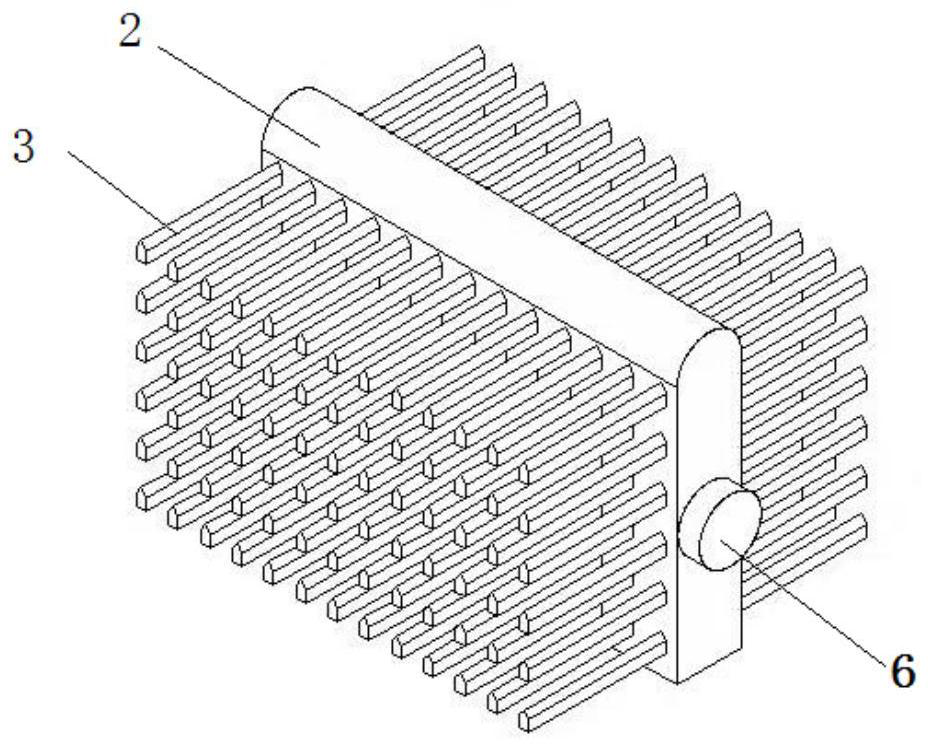

[0042] A kind of cross-flow mixed coal pyrolysis device described in this embodiment, such as Figure 2-7 As shown, it includes a vertical pyrolysis furnace body, and the interior of the vertical pyrolysis furnace body 1 includes a drying unit, a first transition section 8, a pyrolysis unit 1, a second transition section and a cooling unit arranged in sequence from top to bottom , the middle position of the pyrolysis unit is provided with a multilayer gas distribution structure, and the multilayer gas distribution structure includes a vertically arranged gas distribution chamber 2 and a plurality of laterally arranged gas distribution branch pipes 3, the gas distribution The chamber is provided with an air inlet 6, and each of the air distribution branch pipes communicates with the air distribution chamber, and the air distribution branch pipes 3 are evenly arranged on the left and right sides of the air distribution chamber 2, and the air distribution branch pipes on each side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com