Dry quenching dual pressure high-temperature and high-pressure residual heat power generation system

A high-temperature, high-pressure, waste heat power generation technology, which is applied in coke ovens, coke cooling, machines/engines, etc., can solve the problems of high exhaust gas temperature of waste heat boilers, low utilization efficiency of CDQ waste heat, and high power generation costs, and achieve high waste heat The effect of recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

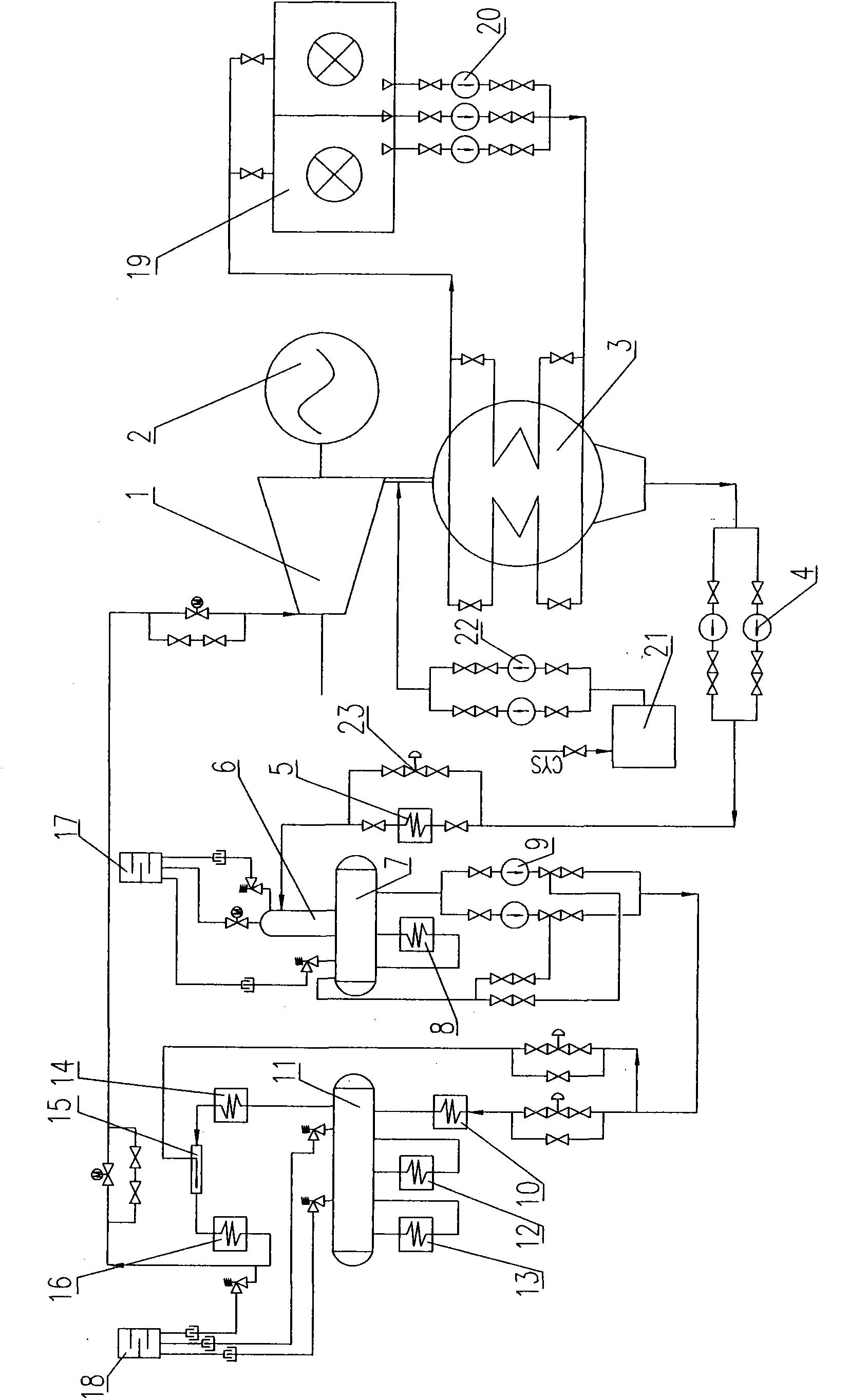

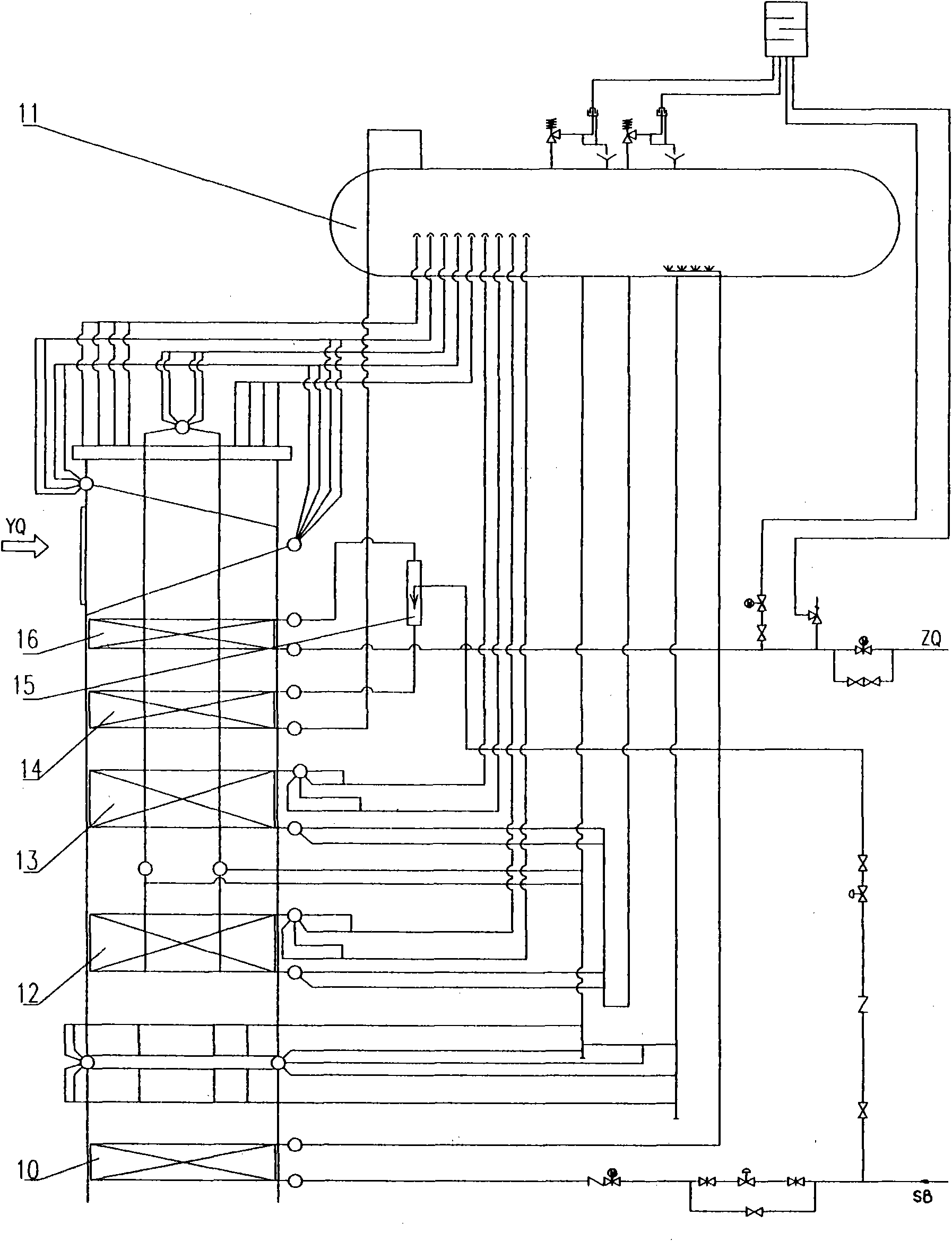

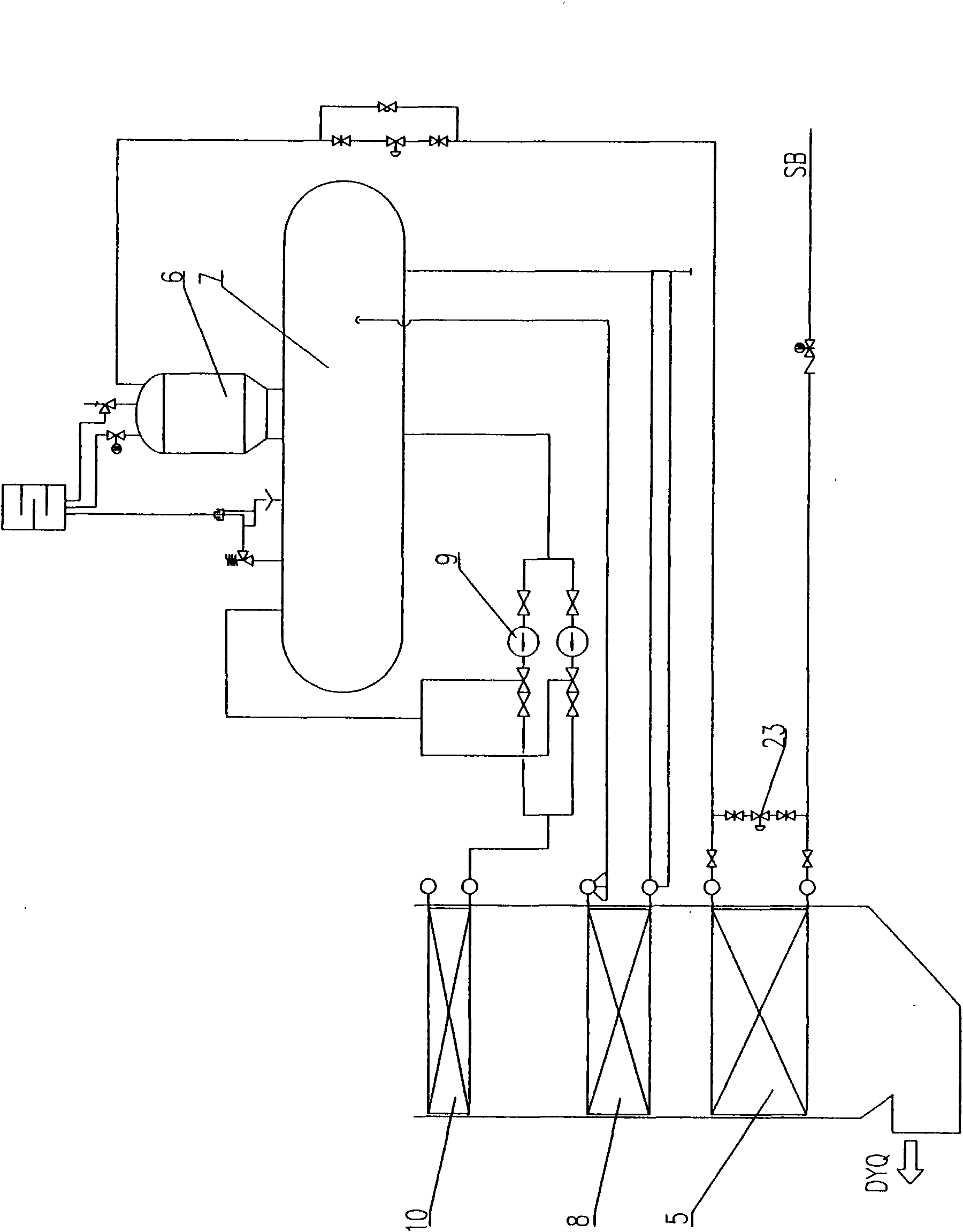

[0024] Such as figure 1 As shown, a CDQ dual-pressure high-temperature and high-pressure waste heat power generation system provided in this embodiment includes a CDQ high-temperature, high-pressure superheated steam dual-pressure waste heat boiler, a turbogenerator set, a condensing device and a condensate pump 4, and is characterized in that: The CDQ high-temperature, high-pressure superheated steam double-pressure waste heat boiler includes: low-pressure economizer 5, high-pressure deaerator 6, low-pressure drum 7, low-pressure evaporator 8, high-pressure economizer 10, high-pressure drum 11, high-pressure fins Tube evaporator 12, high-pressure light tube evaporator 13, high-pressure low-temperature superheater 14, desuperheater 15, high-pressure high-temperature superheater 16; the turbogenerator set includes a steam turbine 1 and a generator 2; the condensing device is a condenser 3. The cooling tower 19 and the circulating water pump 20 form a closed cycle; the condenser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com