Blending sectional material of modified recovery polyethylene and polrvinyl chloride and preparation method of blending sectional material

A polyvinyl chloride and polyethylene technology, applied in the field of polyvinyl chloride profiles and their preparation, can solve the problems of unreachable industrialized production of profiles, complicated processes, poor comprehensive performance, etc., and achieves improved recycling rate, simplified preparation method, The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

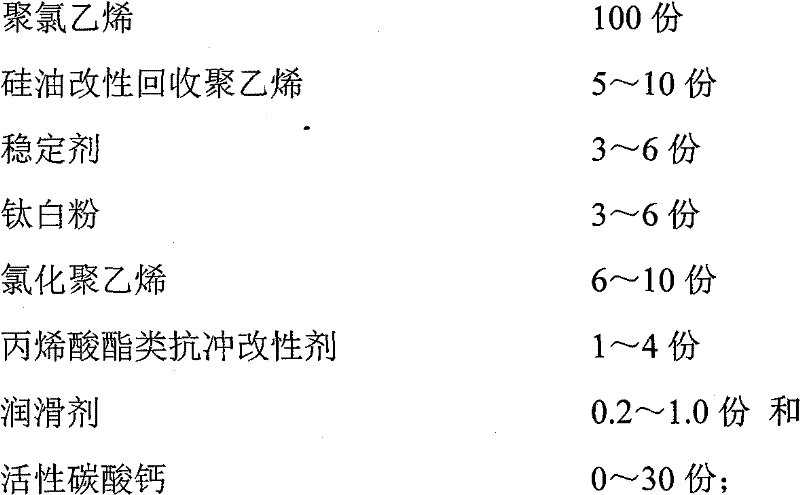

[0029] A modified recycled PE and PVC blended profile of the present invention, the blended profile is prepared by blending the following raw materials in parts by mass:

[0030] PVC 100 parts

[0031] Silicone oil modified recycled PE 5-10 parts

[0032] Stabilizer 3~6 parts

[0033] 3-6 parts of titanium dioxide

[0034] 6-10 copies of CPE

[0035] ACR 1~4 parts

[0036] Lubricant 0.2~1.0 part and

[0037] Active calcium carbonate 0-30 parts.

[0038] The preparation method of the above-mentioned modified reclaimed PE and PVC blend profile of the present invention specifically comprises the following steps:

[0039] (1) Mixing: Mix the raw materials PVC, stabilizer, titanium dioxide, CPE, ACR and lubricant at high speed according to the above mass ratio. The mixed raw materials will generate heat due to friction. When the temperature rises to 80℃~95℃, add silicone oil to modify Recycled PE or add silicone oil modified recycled PE and activated calcium carbonate, hot m...

Embodiment 2

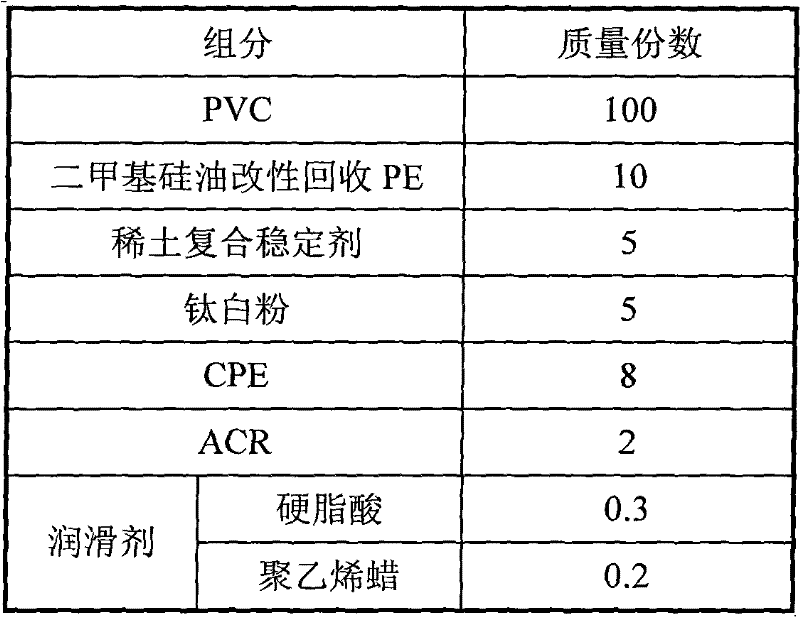

[0044] A modified recycled PE and PVC blend profile of the present invention, the blend profile is prepared by blending the following raw materials in parts by mass:

[0045] PVC 100 parts

[0046] Dimethicone modified recycled PE 5 parts

[0047] Rare earth composite stabilizer 5 parts

[0048] Titanium dioxide 5 parts

[0049] 8 copies of CPE

[0050] ACR 2 copies

[0051]0.3 parts of stearic acid

[0052] Polyethylene wax 0.2 parts and

[0053] Active calcium carbonate 15 parts.

[0054] The blend profile of the modified recycled PE and PVC in this embodiment is specifically prepared by the following method steps:

[0055] 1. Preparation of simethicone modified recycled PE: Add 8 parts of simethicone (viscosity 5000cS) to 100 parts of recycled PE, then stir at high speed for 5 minutes, and extrude the evenly stirred material on twin-screw Extrusion granulation is carried out in the machine, and the working parameters of the twin-screw extruder are:

[0056] Zone 1 ...

Embodiment 3

[0071] This example focuses on the influence of the content of simethicone oil on the properties of the blended profile. The viscosity of simethicone oil is 5000cS.

[0072] The preparation steps of the blended profile of the modified recycled PE and PVC of the present embodiment are as follows:

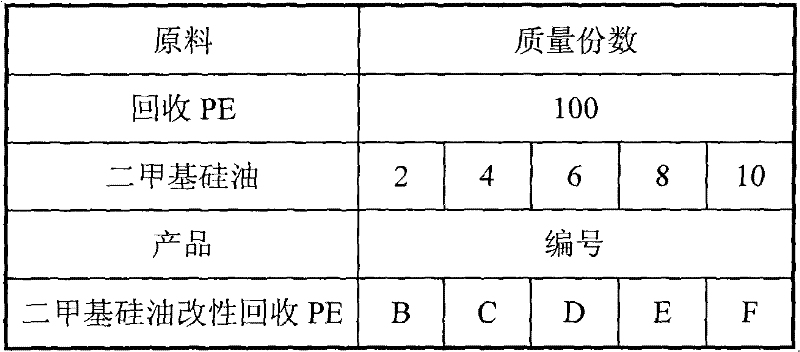

[0073] 1. Preparation of simethicone modified recycled PE: the operation process and process parameters of this step are the same as step 1 in Example 2, but the mass ratio of simethicone used as raw material and recycled PE changes according to certain rules (See Table 2 below), so five different simethicone modified recycled PEs (numbered respectively with B, C, D, E, and F) were finally prepared;

[0074] Table 2: Formulation table of simethicone modified recycled PE in Example 3

[0075]

[0076] 2, mixing materials: the operation process of this step and process parameter are identical with the step 2 in embodiment 2, but the mass proportioning of each raw material changes t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com