Recycled polypropylene modified polrvinyl chloride sectional material and preparation method thereof

A technology for recycling polypropylene and polyvinyl chloride, which is applied in the field of polyvinyl chloride profiles and their preparation, can solve the problems of not meeting the physical performance requirements of PVC profiles, the mechanical properties of finished profiles are not excellent enough, and the preparation process is cumbersome, etc., so as to improve the market Competitiveness, realization of energy and resources, effects of increased recycling rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

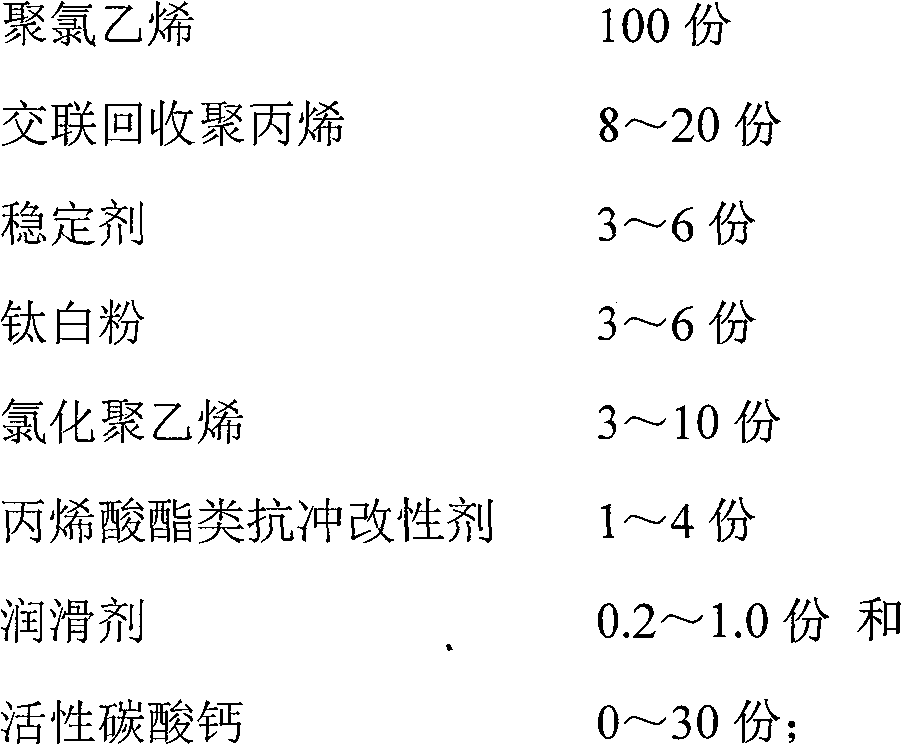

[0030] A PVC profile modified with recycled PP of the present invention, which is prepared by blending the following raw materials in parts by mass:

[0031] PVC 100 parts

[0032] 8-20 parts of cross-linked recycled PP

[0033] Stabilizer 3~6 parts

[0034] 3-6 parts of titanium dioxide

[0035] CPE 3~10 parts

[0036] ACR 1~4 copies

[0037] Lubricant 0.2~1.0 part and

[0038] Active calcium carbonate 0-30 parts.

[0039] The above-mentioned preparation method of the modified PVC profile with recycled PP of the present invention specifically comprises the following steps:

[0040] (1) Mixing: mix the raw materials PVC, stabilizer, titanium dioxide, CPE, ACR and lubricant at high speed according to the above ratio, and add cross-linked recovery PP or cross-linked recovery when the temperature rises to 80℃~95℃ PP and activated calcium carbonate, heat mixed until the temperature reaches 115 ℃ ~ 125 ℃, discharge, and then start cold mixing to room temperature to obtain a ...

Embodiment 2

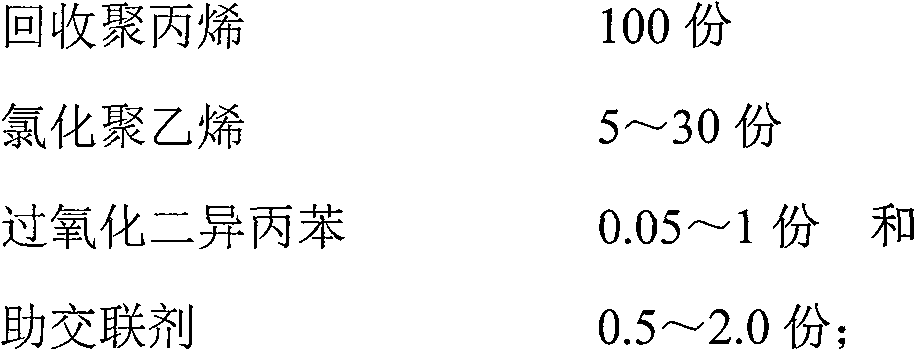

[0045]According to the component list in Table 1, prepare raw materials for recycled PP (the melt index of recycled PP is less than 12.0g / 10min, and the solid content is less than 15%), CPE, DCP and co-crosslinking agent (styrene or divinylbenzene) , dissolve DCP in the co-crosslinking agent, then spray the solution on the recycled PP and CPE, then put it into the high-speed mixer and mix it for 5 minutes before discharging (the speed of the high-speed mixer reaches 700rpm); Extrude and granulate with a twin-screw extruder at a temperature of 120°C to 180°C to prepare three types of cross-linked recycled PP with different ratios for use.

[0046] Table 1: Different formulations of cross-linked recycled PP

[0047]

[0048] Raw material PVC (PVC-SG-5), rare earth composite stabilizer, titanium dioxide, CPE, ACR and lubricant (the lubricant selected in this embodiment is stearic acid and polyethylene wax) are listed in the following table 2. Then add it to the high-speed mix...

Embodiment 3

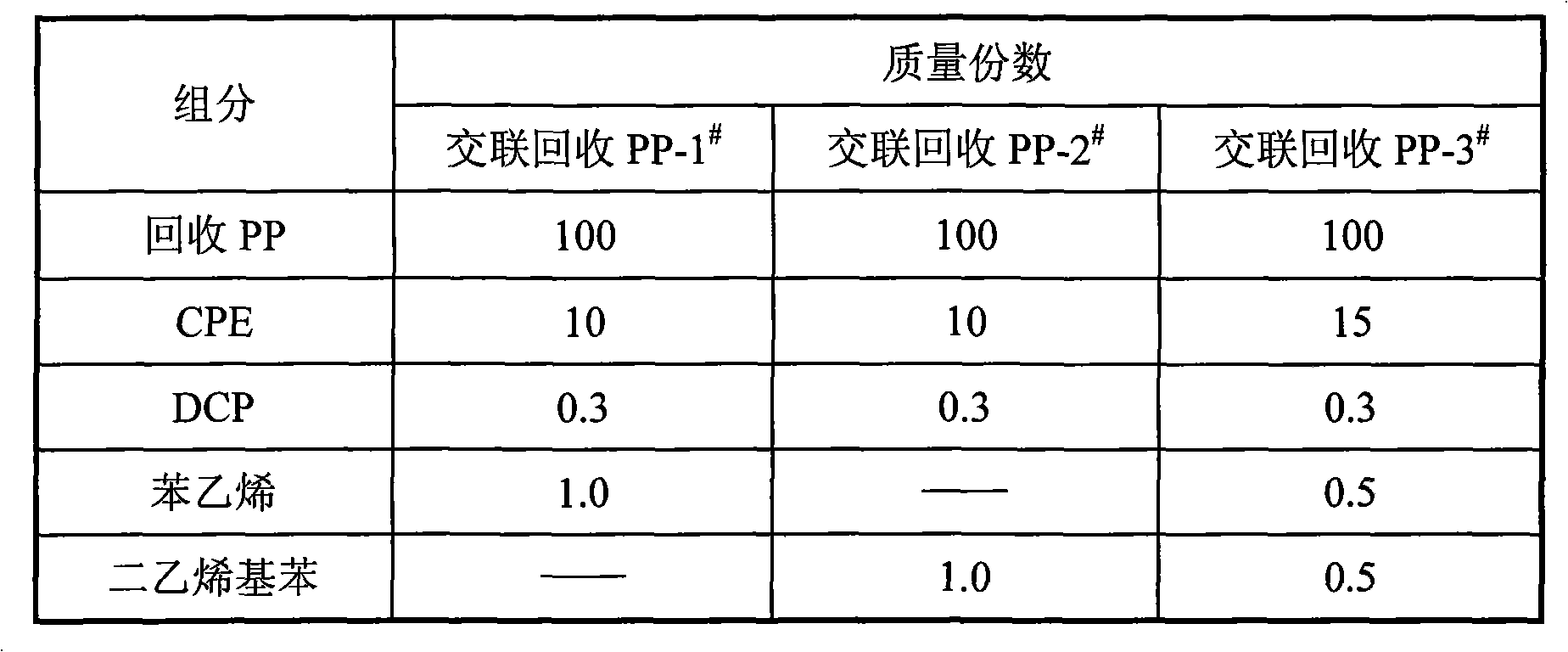

[0057] This embodiment 3 selects the cross-linked recovery PP-1 prepared in embodiment 2 # As the raw material component for preparing the modified PVC profile of the present invention, the mass parts formula of the remaining components and each component is shown in the following table 4, and the mass parts of the active calcium carbonate component are divided into four different additions one by one Adjustment, the mass parts of other components remain unchanged, according to the method and process described in Example 2 (including cross-linking pretreatment) to prepare four kinds of recycled PP modified PVC profiles with different active calcium carbonate content.

[0058] Table 4: The PVC profile formula table of the present invention that makes in embodiment 3

[0059]

[0060] The mechanical properties of the recycled PP-modified PVC profiles with four different active calcium carbonate contents prepared in Example 3 were compared with the profile C prepared in Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com