Novel high-temperature recycled sand cooling system and waste heat recovery method

A cooling system, a technology for reclaiming sand, applied in foundry molding equipment, machinery for cleaning/processing of casting materials, metal processing equipment, etc. Cooling speed and the effect of improving waste heat recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

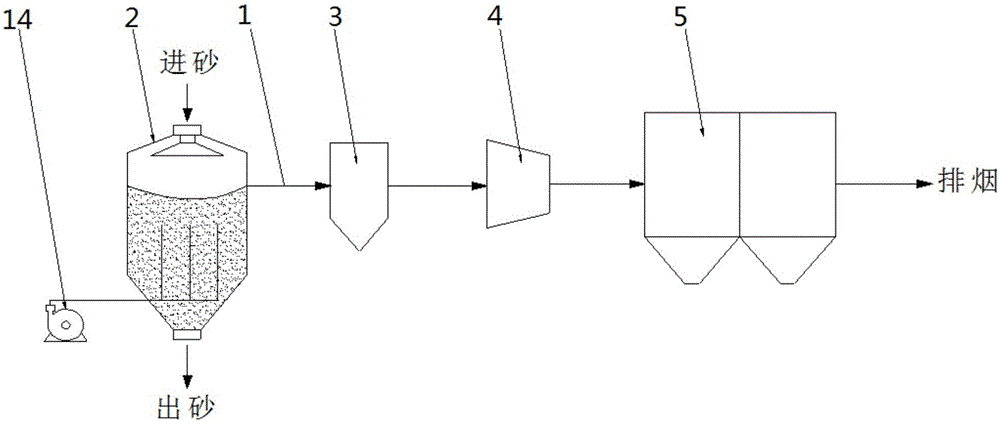

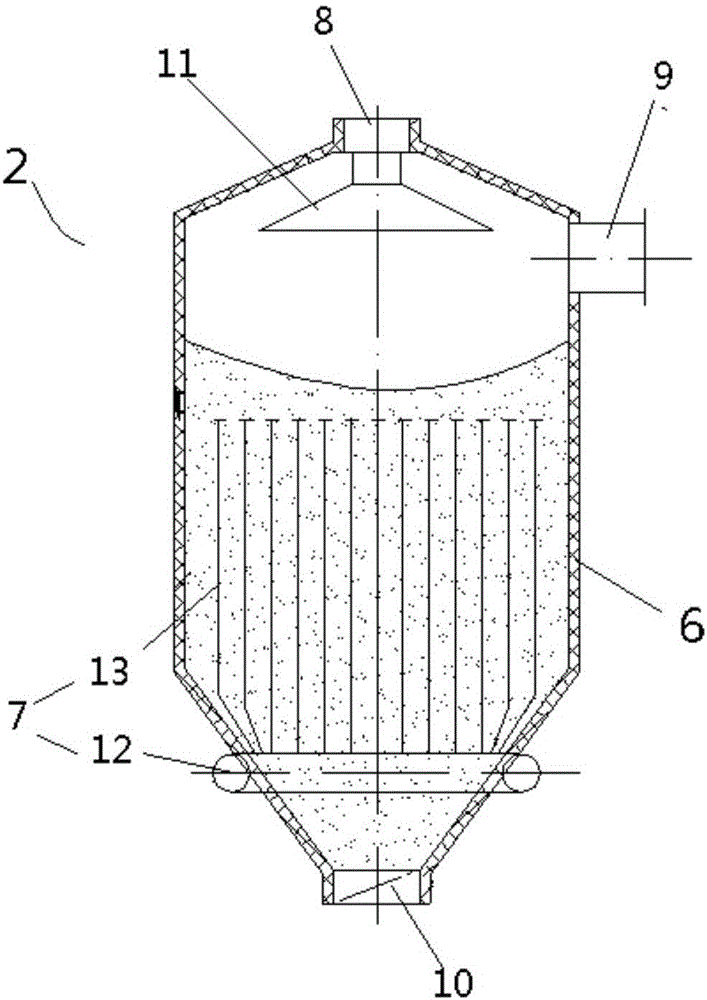

[0021] Such as figure 1 As shown, a new type of high-temperature reclaimed sand cooling system in this embodiment includes a vertical tank type primary cooler 2, a gravity dust collector 3, a flue gas-type organic Rankine generator set 4, and a bag filter connected sequentially through a pipeline 1. 5. The vertical tank type primary cooler 2 includes a shell 6 and a cooling device 7. The top of the shell 6 is provided with a feed port 8 and an air exhaust port 9, and a discharge valve 10 is provided below, and the material is fed into the shell 6. A disc distributor 11 is arranged below the mouth, and the cooling device 7 includes an air supply surrounding pipe 12 arranged in a ring at the outer bottom area of the casing and a plurality of heat exchange air supply pipes arranged longitudinally in the casing in communication with the air s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com