Optimization and control integrated design method for tail gas waste heat recovery organic Rankine cycle

A Rankine cycle, waste heat recovery technology, applied in computer-aided design, calculation, special data processing applications, etc., can solve the problem of large amount of calculation, the optimal operating point is not easy to reach the safety threshold, and does not consider system uncertainty and control. performance and other issues, to achieve the effects of good robustness, improved waste heat recovery efficiency, and optimized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In the following, an organic Rankine cycle system for exhaust waste heat recovery in a certain laboratory is taken as an example. For ease of understanding, this embodiment takes automobile exhaust recovery as an example to describe the integrated design method of optimization and control in detail.

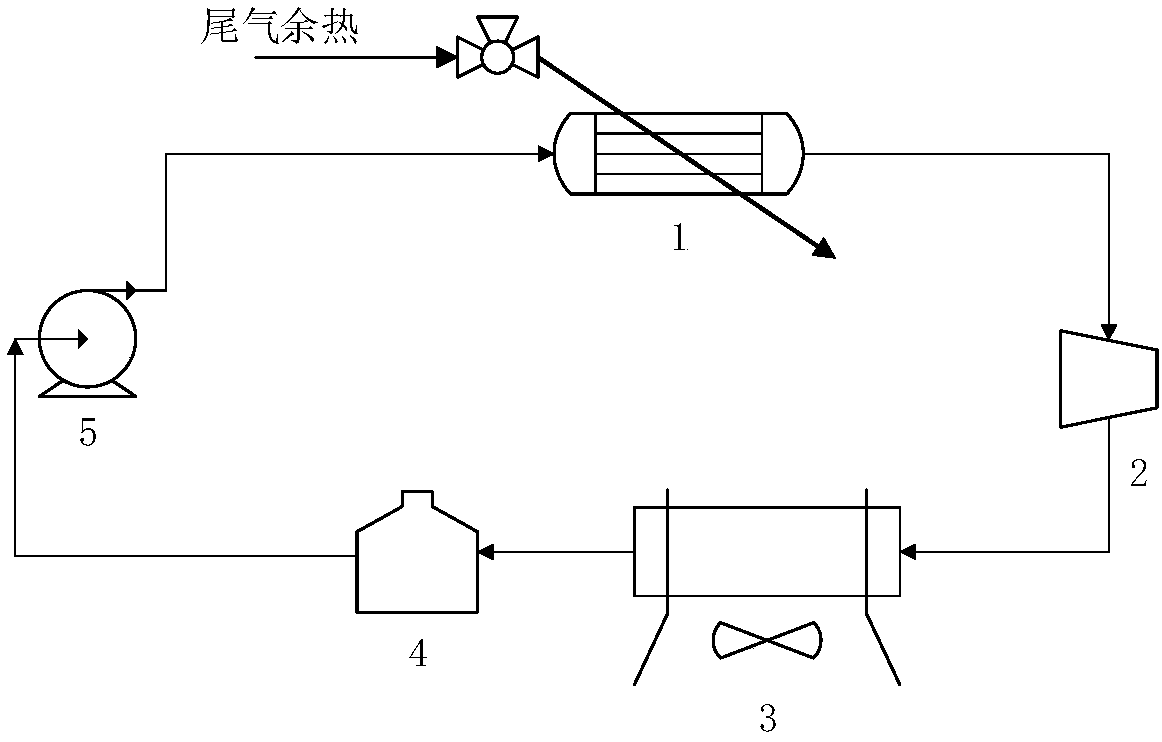

[0043] The structure of the organic Rankine cycle system is as follows figure 1 As shown, R245fa is selected as the circulating working fluid, which is mainly composed of five components: evaporator 1, expander 2, condenser 3, liquid storage tank 4 and booster pump 5.

[0044]Its basic working principle is that the low-temperature and low-pressure circulating working medium (i.e. working medium) enters the evaporator 1 after being pressurized by the booster pump 5, evaporates into a high-temperature and high-pressure gas after absorbing the waste heat of automobile exhaust, and then enters the expander 2 to expand and do work. The exhaust gas of the circulating working med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com