Centrifugal type fusion slag quenching and dry type granulating, and waste heat recovery power generation system and method

A technology for melting slag and waste heat recovery, applied in recycling technology, furnace, waste heat treatment, etc., can solve the problems of wasting water resources, heavy system maintenance workload, consumption of new water, etc., to avoid losses and improve waste heat recovery efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

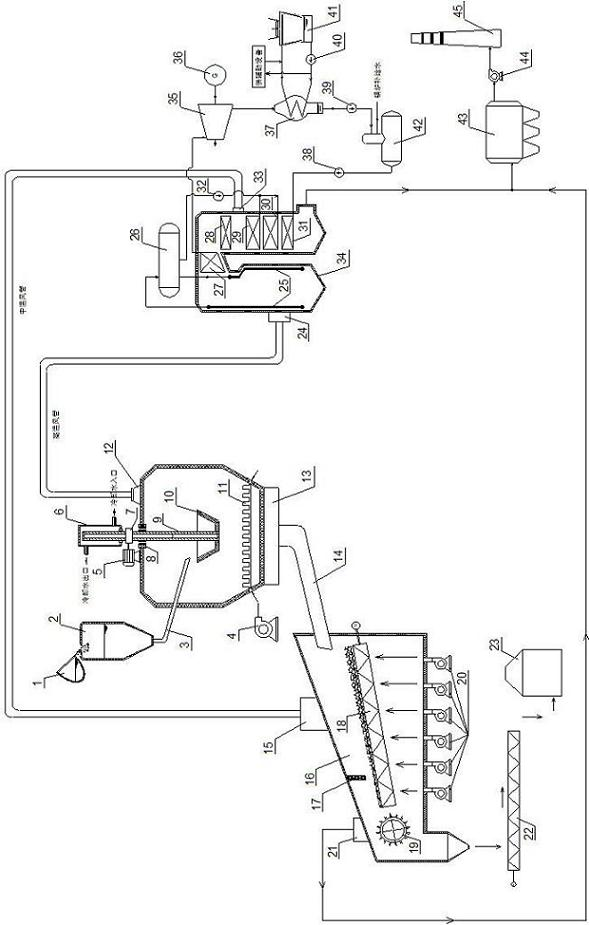

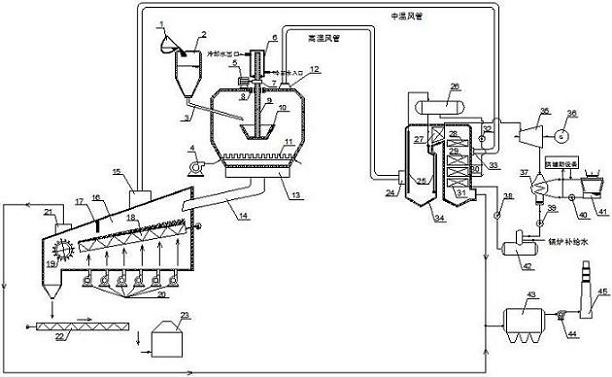

[0028] The specific embodiment that realizes the method of the present invention is as follows:

[0029] 1. The molten slag at 1400-1600°C is sent to the slag storage tank 2 through the slag receiving tank 1 for storage.

[0030] 2. The molten slag in the slag storage tank enters the centrifugal granulation furnace 13 through the slag trough 3, and is broken into small particles below 5mm under the action of the centrifugal granulation device, and the temperature of the slag is lowered by the cold air blown in by the primary blower 4 at the same time. Rapid cooling to about 900°C.

[0031] 3. The water-cooled jacket on the upper part of the heat pipe shaft generates hot water at about 80°C, which enters the pipe network for subsequent central heating or cooling.

[0032] 4. The crushed and quenched slag particles fall onto the water-cooled vibrating grate bed 18 in the cooler 16, and exchange heat with the cold air blown in by the secondary blower 20 of the cooler, and then u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com