Mechanical transmission system for extra-large vertical axis wind power generation device

A technology of wind power generation device and mechanical transmission system, which is applied to wind turbine components, wind turbines, wind turbine combinations, etc., can solve the problems of reduced power generation efficiency, failure to reach starting torque, failure to start power generation smoothly, etc. Novel, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with example the present invention will be further described.

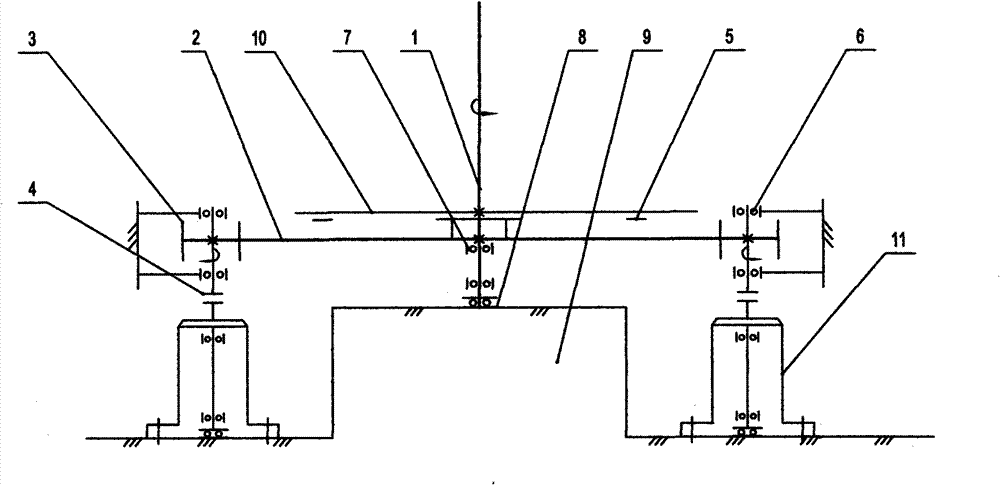

[0011] Such as figure 1 As shown, the mechanical transmission system of this 1.2MW ultra-large vertical axis wind power generation device includes a vertical shaft 1 with a diameter of d = 600mm, a central gear 2 fixed on the vertical shaft 1, and the diameter of the central gear 2 is d 1 =4250mm, number of teeth Z 1 =17, four 300KW generators 11 and base 9. The generator 11 is a vertical structure, and the axis of the generator is installed perpendicular to the base 9; the base 9 at the bottom of the vertical shaft 1 is provided with a load-bearing bearing group 8, and the vertical shaft 1 is fixed by the load-bearing bearing group 8 and the support bearing 7. Around the central gear 2, four satellite gears 3 connected to the rotating shaft of the generator 11 are correspondingly arranged through bearings 6, and the diameter of the satellite gear 3 is d 2 =425mm, number of teeth Z ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com