Guardrail device for highway

a technology for guardrails and highways, applied in roadways, roadway safety arrangements, construction, etc., can solve the problems of poor impact resistance, easy oxidation and rusting, and low safety of use, so as to improve impact resistance and prolong life performance , the effect of low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

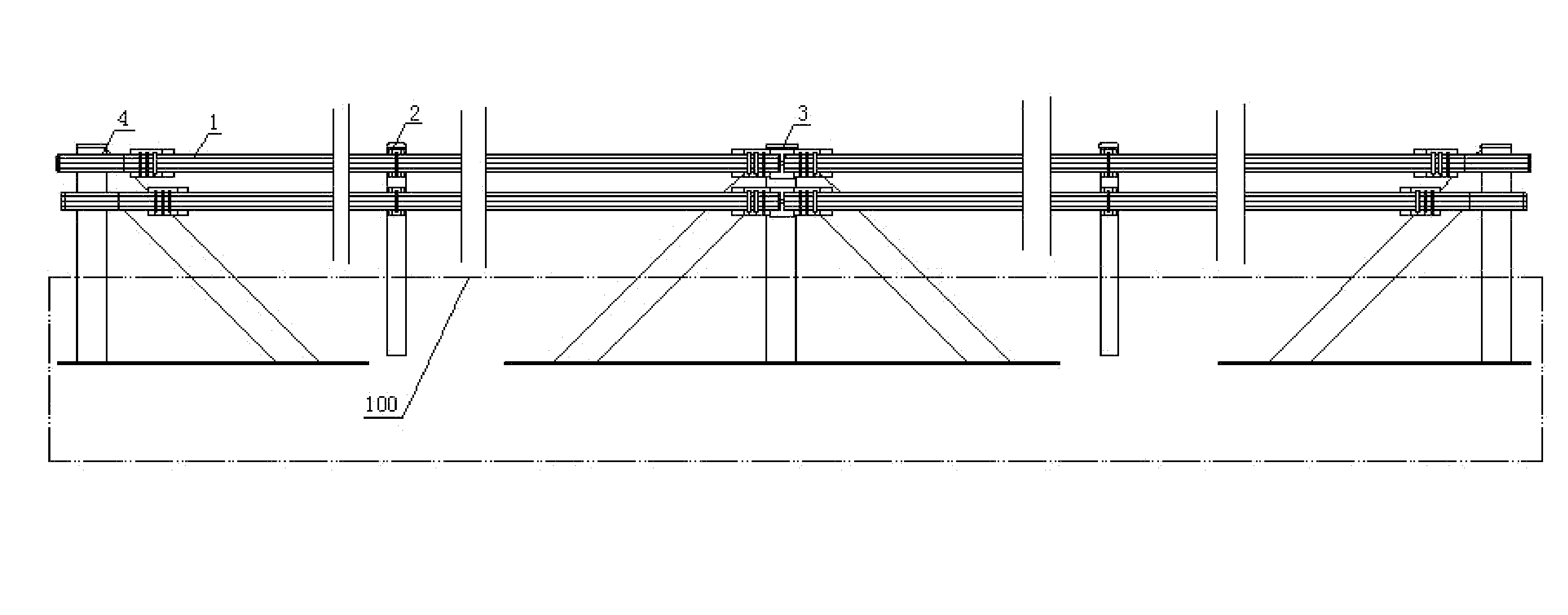

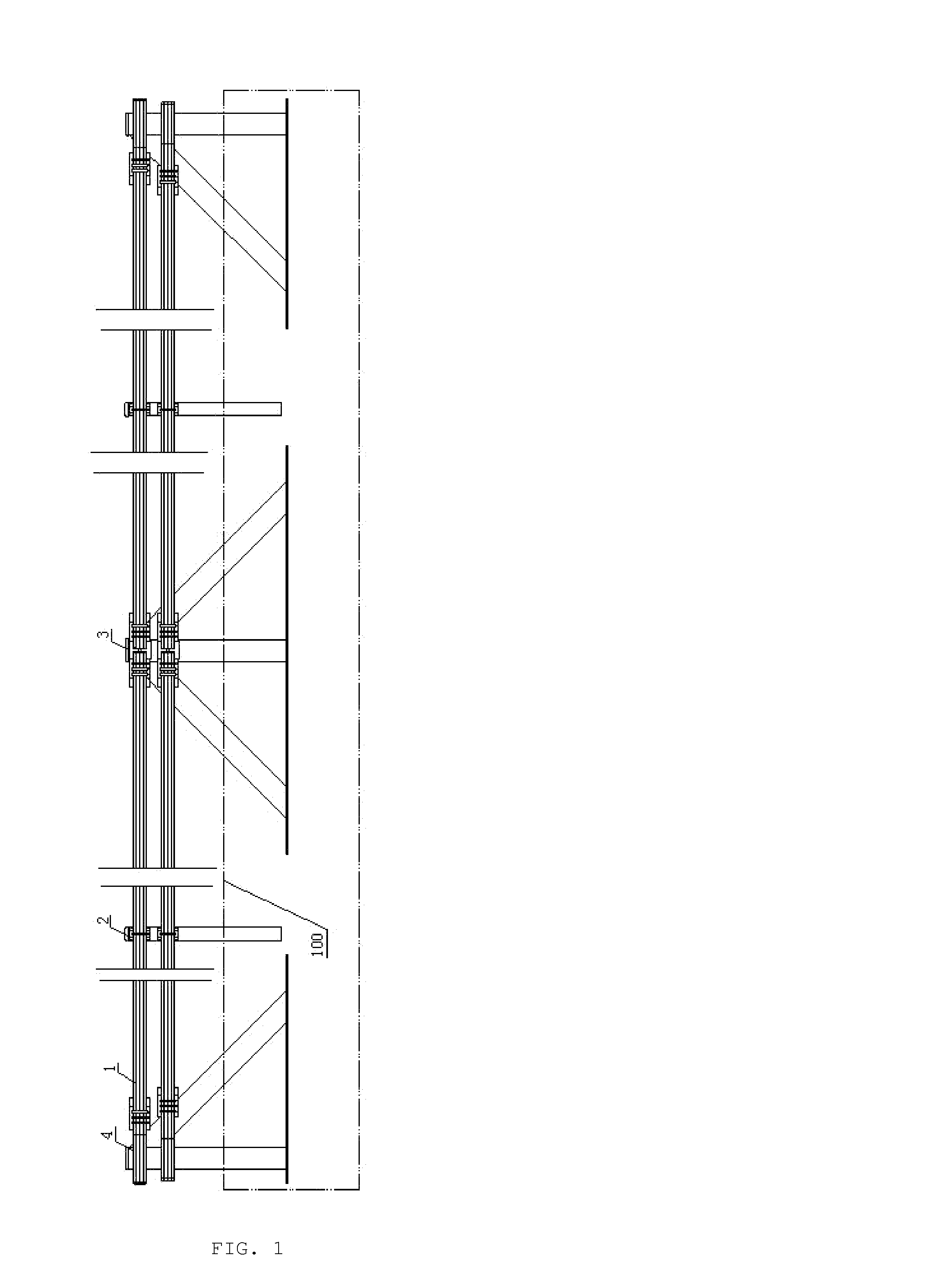

[0049]Referring to FIG. 1 to FIG. 19, the present invention will be illustrated by one embodiment in which there are two guardrail plates and convexes are arranged on each guardrail plate.

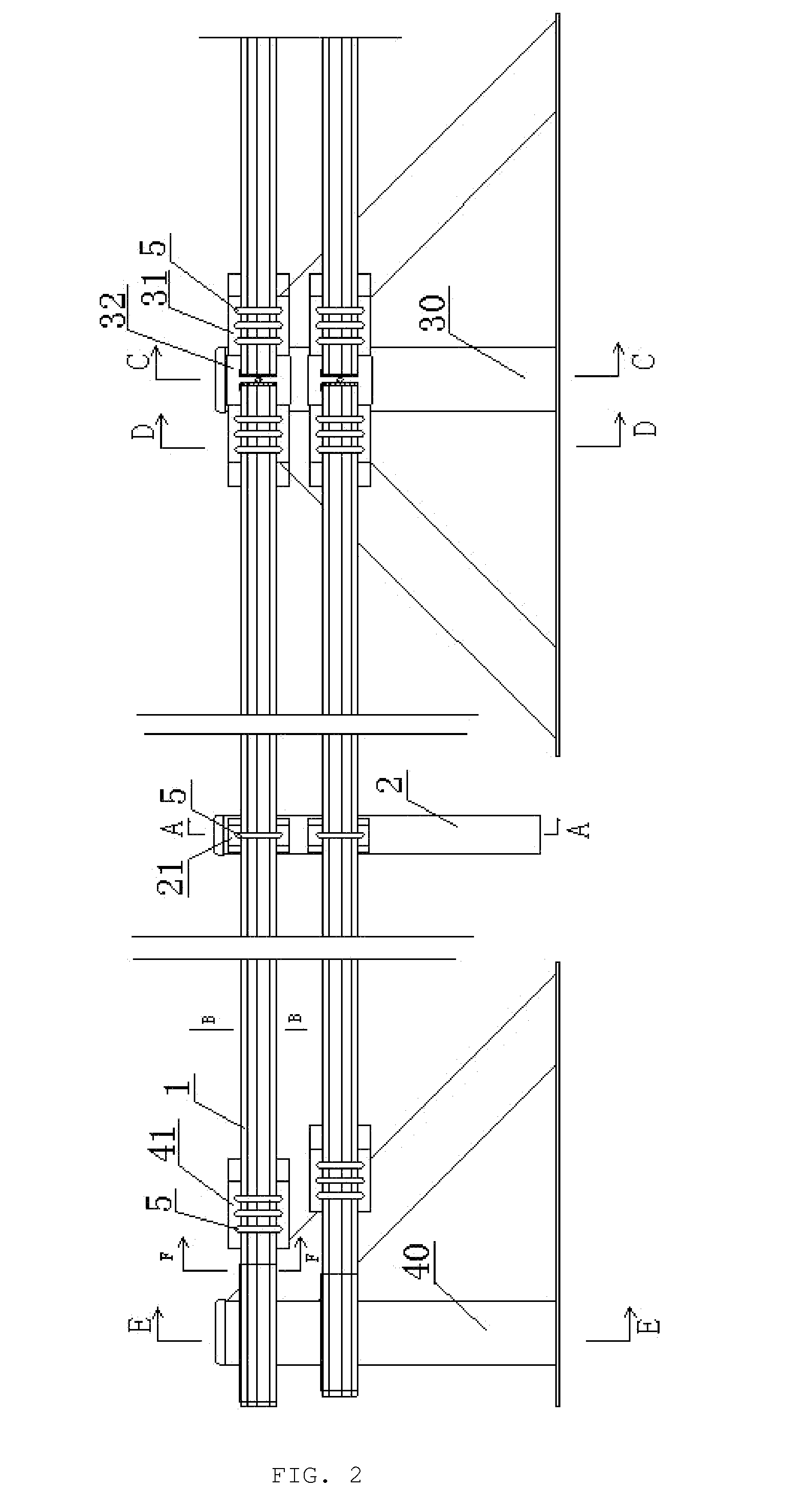

[0050]The current invention comprises guardrail plates 1, a small vertical column 2, a middle large vertical column mechanism 3 and an end large vertical column mechanism 4. Among them, the guardrail plates 1 comprise guardrail plates having end portions 1, the guardrail plates having end portions 1 comprise an end guardrail plate 11 and a middle guardrail plate 12 which are fused together. The middle large vertical column mechanism 3 comprises a middle connecting plate 31, a connecting ring 32 and guardrail plates having end portions 1. End large vertical column mechanism 4 comprises a sheath 42, end connecting plate 41 and guardrail plates having end portions 1.

[0051]The guardrail plates 1, which are formed by PVC resin, have reinforcing bands 13 fixed inside. In the embodiment, seven raised line...

embodiment 2

[0069]With reference to FIG. 20-FIG. 24, this represents the embodiment of the present invention in the case when the guardrail plate takes a wave-form structure.

[0070]The waveform guardrail plate 7 of the present invention includes wave-like structure protrusion 71, reinforcing bands 72 which are located at both sides of the bottom of the waveform guardrail plate 7; the reinforcing bands are fixed into the waveform guardrail plate 7; the outer surface of the waveform guardrail plate 7 is made of PVC resin.

[0071]In this embodiment, a bracket 21 is set between the small vertical column 2 and the waveform guardrail plate 7, the bracket 21 is fixed to the small vertical column 2 by an ordinary bolt, whereas the flat portion 73 of the waveform guardrail plate 7 is fixed to the bracket 21 via frame bolts 5.

[0072]In this embodiment, the middle connecting plate 31 in the middle large vertical column mechanism 3 is located between the middle large vertical column 30 and the connecting ring ...

embodiment 3

[0076]Referring to FIG. 25 to FIG. 29, this represents the embodiment of the present invention in the case when the guardrail plate gets a circular structure.

[0077]The shape of the cross section of the guardrail plate of the present invention is round. The circular guardrail plates 8, which therein coats reinforcing bands 82, is presented to be a long strip in the extension direction, the outer surface of the circular guardrail plate 8 is formed by PVC resin; Multiple guardrail plates may be used in practice.

[0078]In the embodiment, brackets 21 are set between the small vertical column 2 and the circular guardrail plates 8, the brackets 21 are fixed to the small vertical column 2 by ordinary bolts; whereas the circular guardrail plates 8 are fixed to the bracket 8 via frame bolts 5.

[0079]In this embodiment, the middle connecting plate 31 of the middle large vertical column mechanism 3 is located between the middle large vertical column 30 and the connecting ring 31, the middle conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com