Robot for installing aerial curtain wall

A robot and curtain wall technology, which is applied in the fields of construction, building structure, and building material processing, can solve problems that cannot be solved in the high-altitude environment and high-rise building operating environment, and achieve reduced labor intensity, beautiful appearance, and high-quality design. well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings, but this does not limit the protection scope of the claims of the present application.

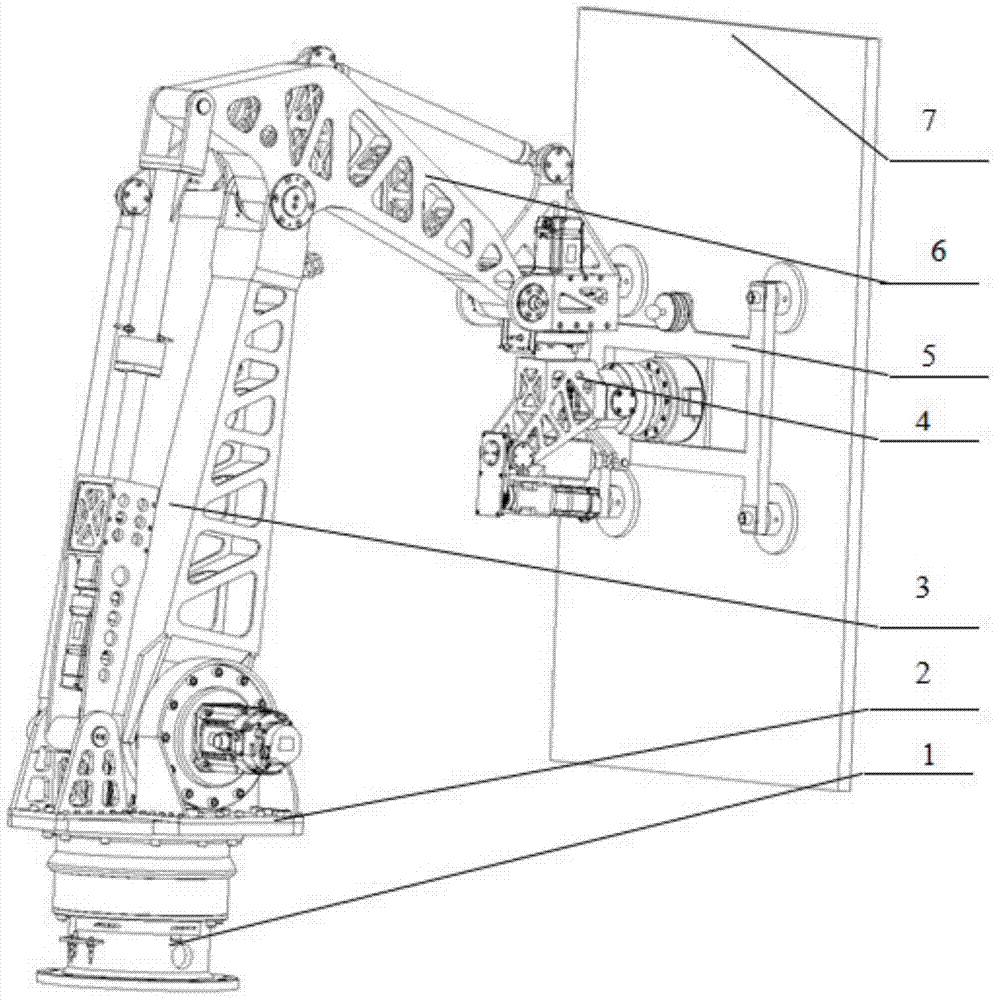

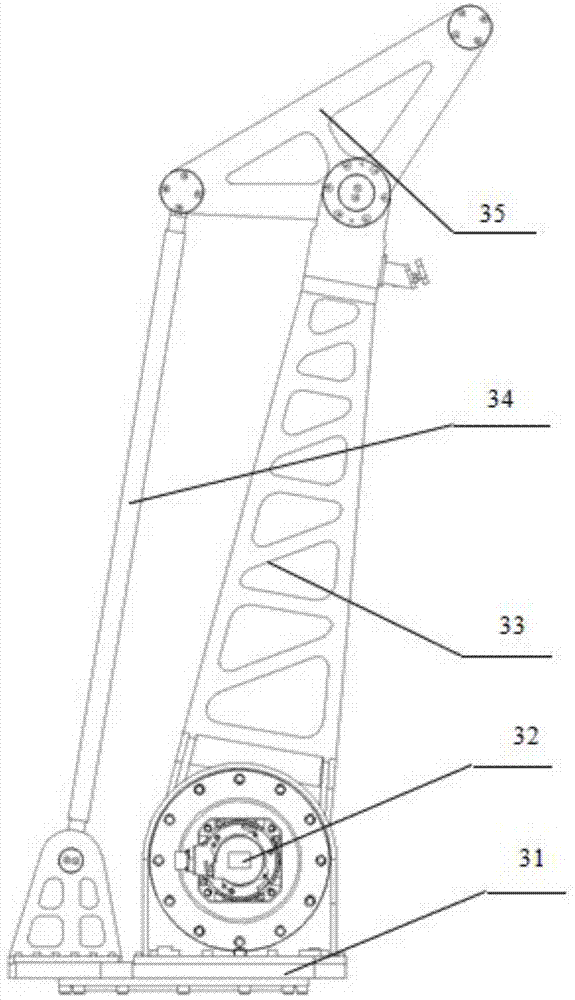

[0015] The high-altitude curtain wall installation robot of the present invention (abbreviation robot, see Figure 1-6 ) includes a base 1, a rotating frame 2, a large arm parallelogram mechanism 3, an end posture adjustment device 4, an end effector 5 and a small arm parallelogram mechanism 6; the base 1, the rotating frame 2, and the large arm parallelogram mechanism 3. The forearm parallelogram mechanism 6, the terminal attitude adjustment device 4 and the end effector 5 are connected in sequence;

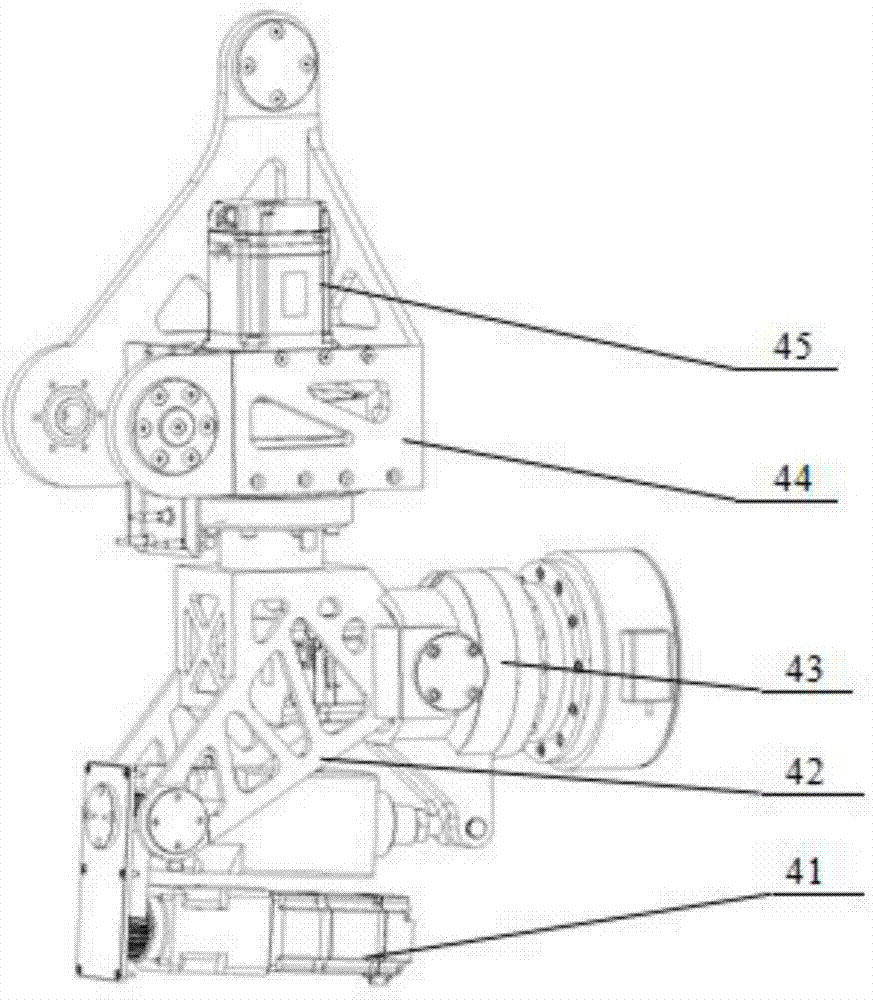

[0016] The terminal attitude adjustment device 4 includes an electric push rod assembly 41, a fixed bracket 42 for pitching, a six-axis motor-RV reducer assembly 43, a four-axis motor-RV reducer assembly 45, and a fixed bracket 44 for swing; The middle part of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com