Indexable drill, cutting insert and drill main body

A technology of indexing inserts and cutting inserts, used in drilling/drilling equipment, repair drills, twist drills, etc., can solve the problems of wear on the torque bearing surface and torque transmission surface, shorten the life of the drill bit, etc., to prevent wear and tear. , The effect of stable drilling and scratch prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

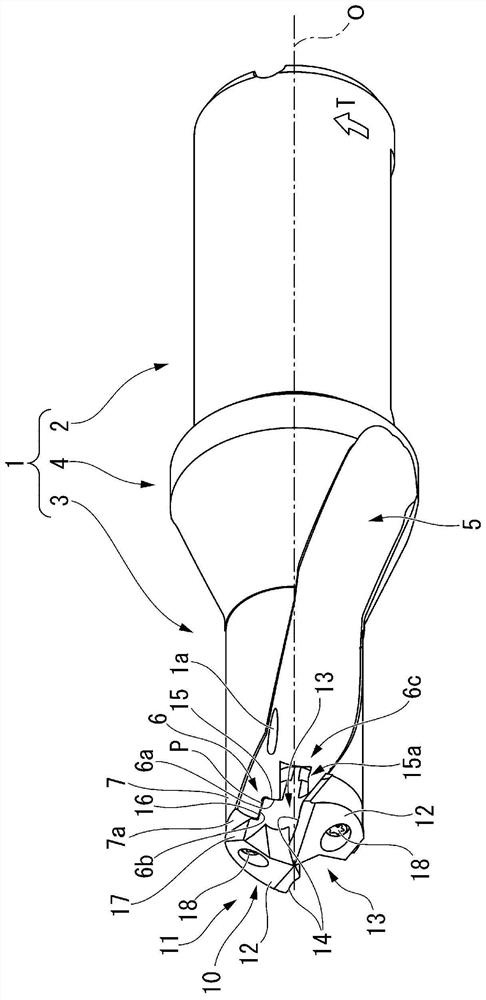

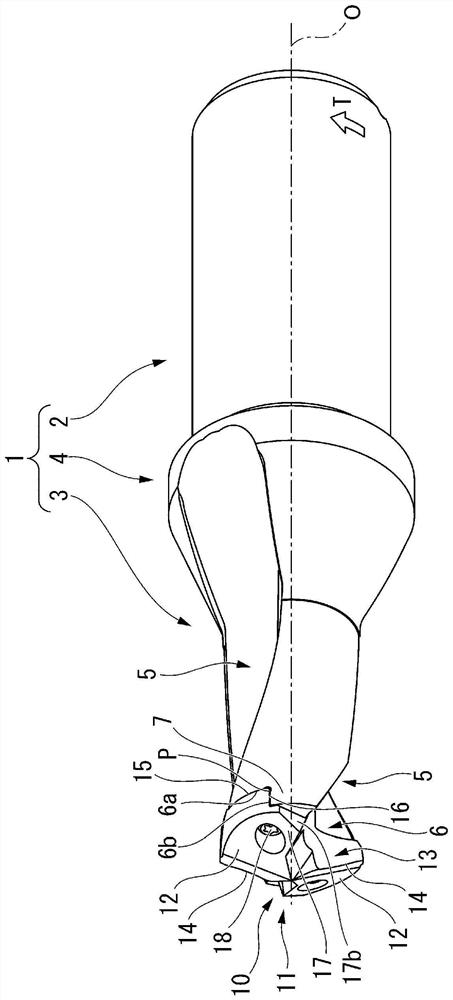

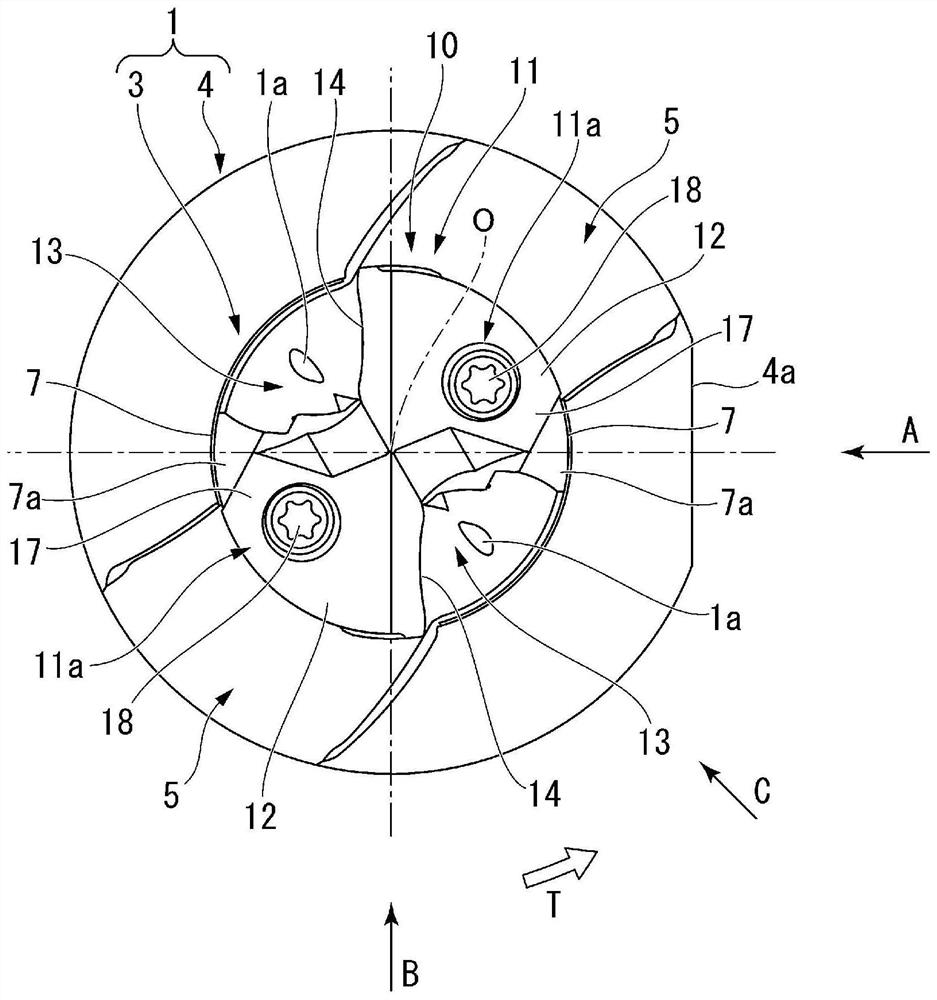

[0056] Figure 1 to Figure 6 The first embodiment of the indexable insert drill in the present invention is shown, Figure 7 An exploded view of the indexable insert drill according to the first embodiment is shown. Figure 8 and Figure 9 A first embodiment showing the drill main body used in the indexable insert drill according to the first embodiment, Figure 10 ~ Figure 14 A first embodiment of a cutting insert detachably attached to the drill body is shown.

[0057] The drill body 1 is formed of a metal material such as steel into a multi-stage cylindrical shape centered on the axis O. As shown in FIG. The rear end of the drill body 1 (in figure 1 , figure 2 , Figure 4 ~ Figure 7 and Figure 9 The middle is the right side part) is the large diameter handle 2, the front end (in figure 1 , figure 2 , Figure 4 ~ Figure 7 and Figure 9 The left part in the middle) is the cutting edge portion 3 of the insert body 11 to which the cutting insert 10 is detachably a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com