Drilling tool

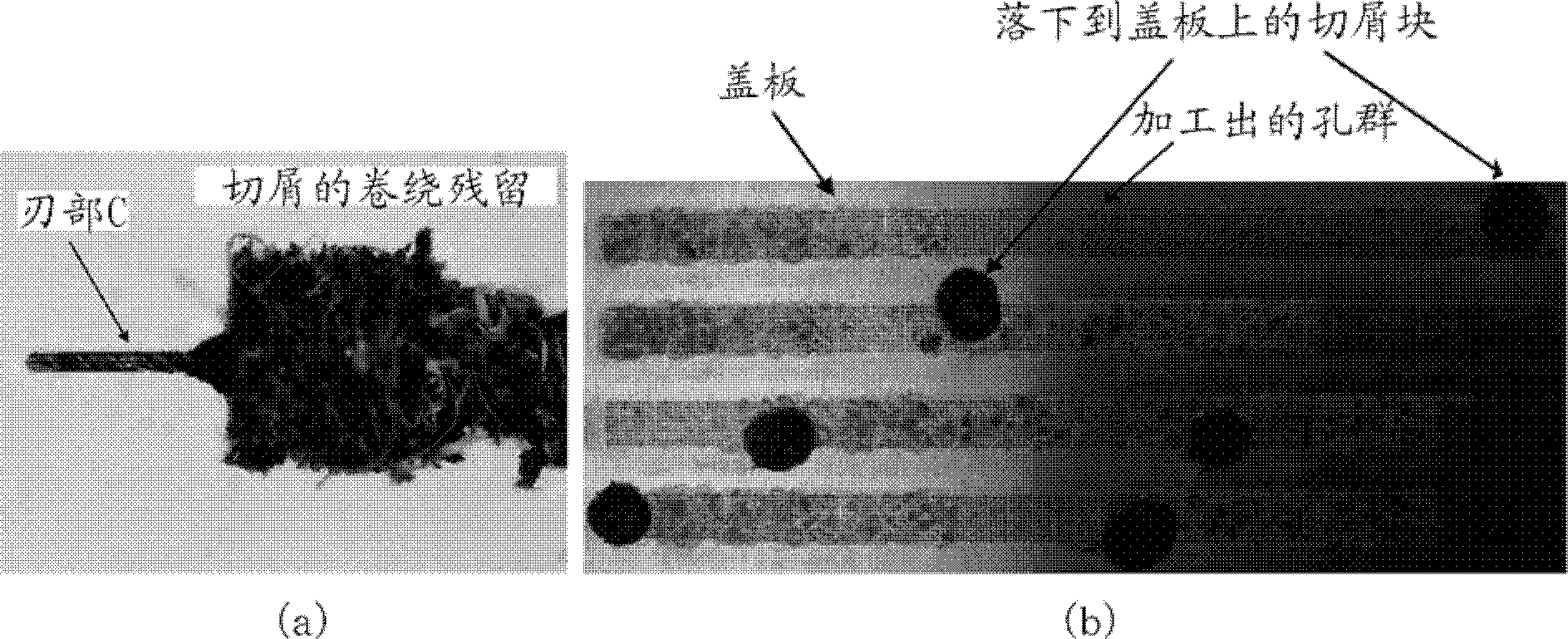

A technology for drilling tools and tools, applied in drilling accessories, manufacturing tools, drilling/drilling equipment, etc., can solve the problems of chip winding without mentioning, and achieve excellent practicability, stable drilling processing, and prevent The effect of winding of chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] based on Figure 4 ~ Figure 10 Specific examples of the present invention will be described.

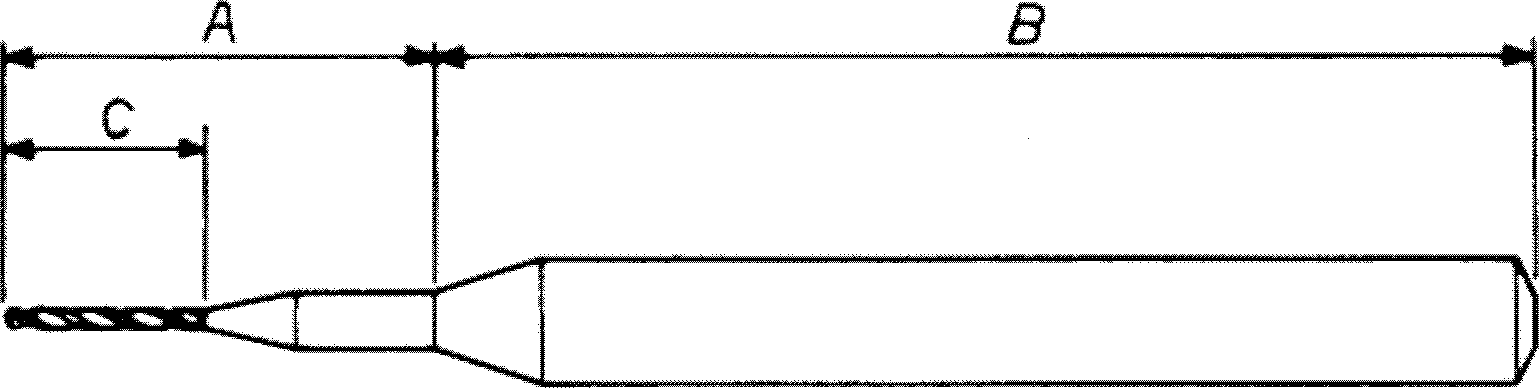

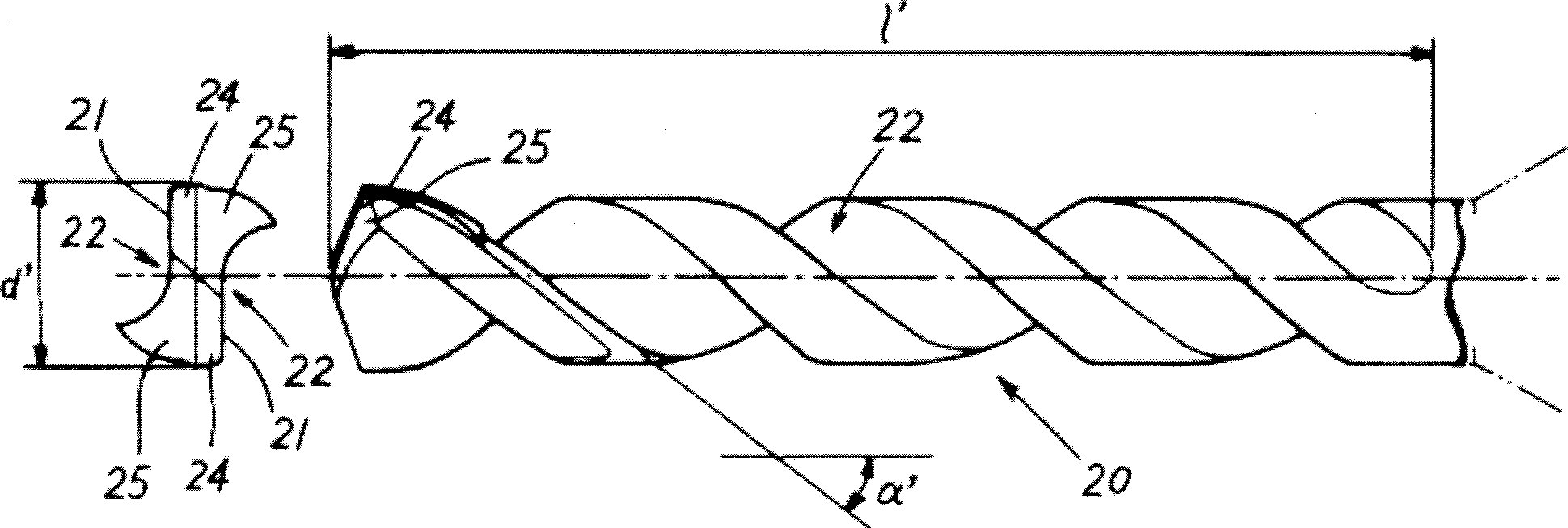

[0054] This embodiment is a drilling tool as follows: one or more cutting edges are provided at the end of the tool main body 1, and a plurality of helical cutting edges are provided on the outer periphery of the tool main body 1 from the end of the tool toward the base end side. Chip removal flutes, the plurality of chip removal flutes at least include one main flute 2a and one auxiliary flute 2b, and one or more auxiliary flutes 2b are arranged in the middle of the main flute 2a and the main flute 2a In addition, the drilling tool is provided with a step difference 7 at the confluence part 6 where the main groove 2a and the secondary groove 2b meet.

[0055] Specifically, the present embodiment is a drill bit as follows: the tool diameter is 0.075mm, and one main groove 2a and one auxiliary groove 2b are respectively provided, and the groove length l of the main groove 2a i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com