Full-hydraulic multifunctional driller for gas extraction, drainage and discharge

A multi-functional, fully hydraulic technology, used in gas discharge, rotary drilling rigs, earth-moving drilling, etc., can solve the problems of many processes, poor guide rail, unreliable clamping, etc., and achieve high guiding accuracy, strong rigidity and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

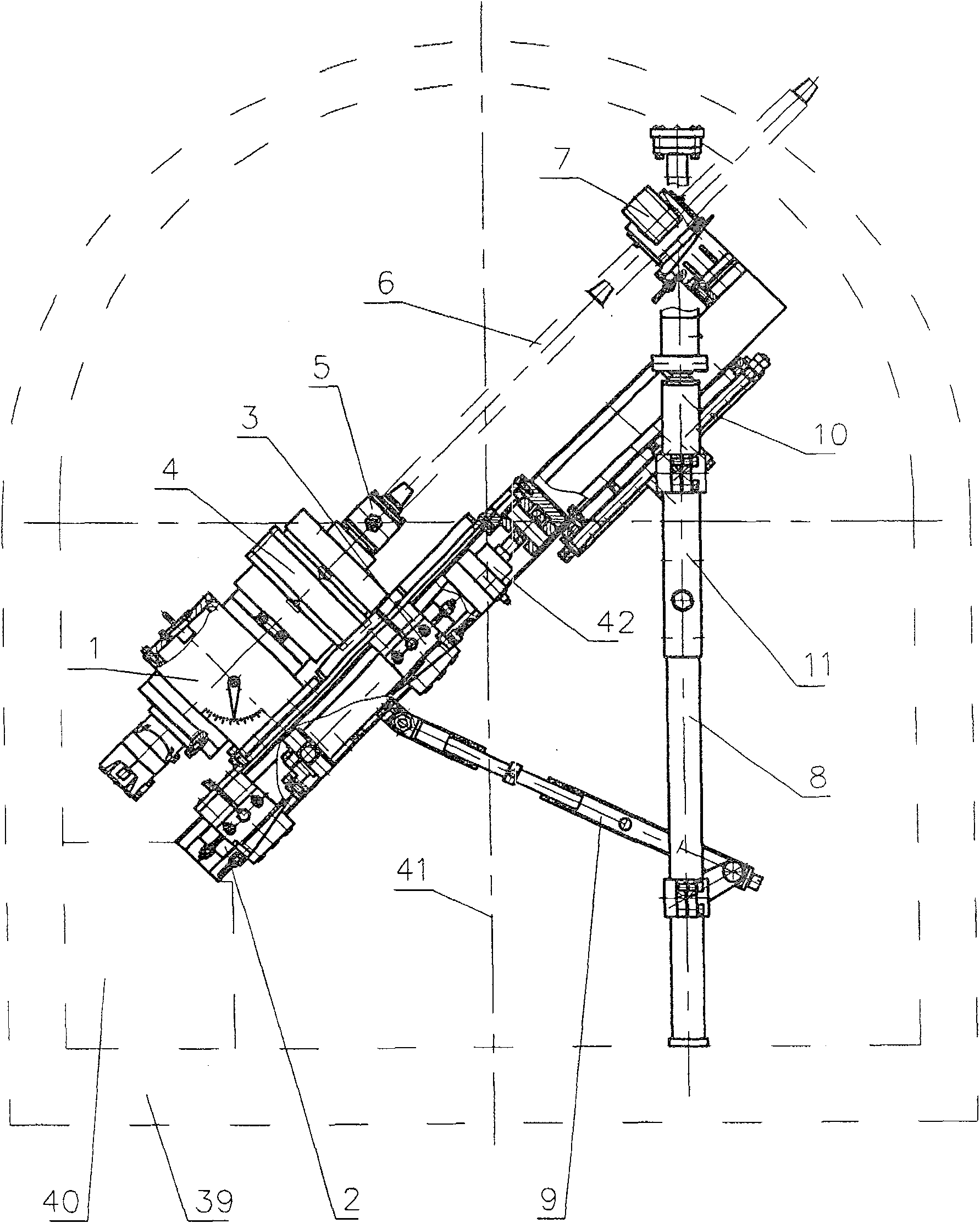

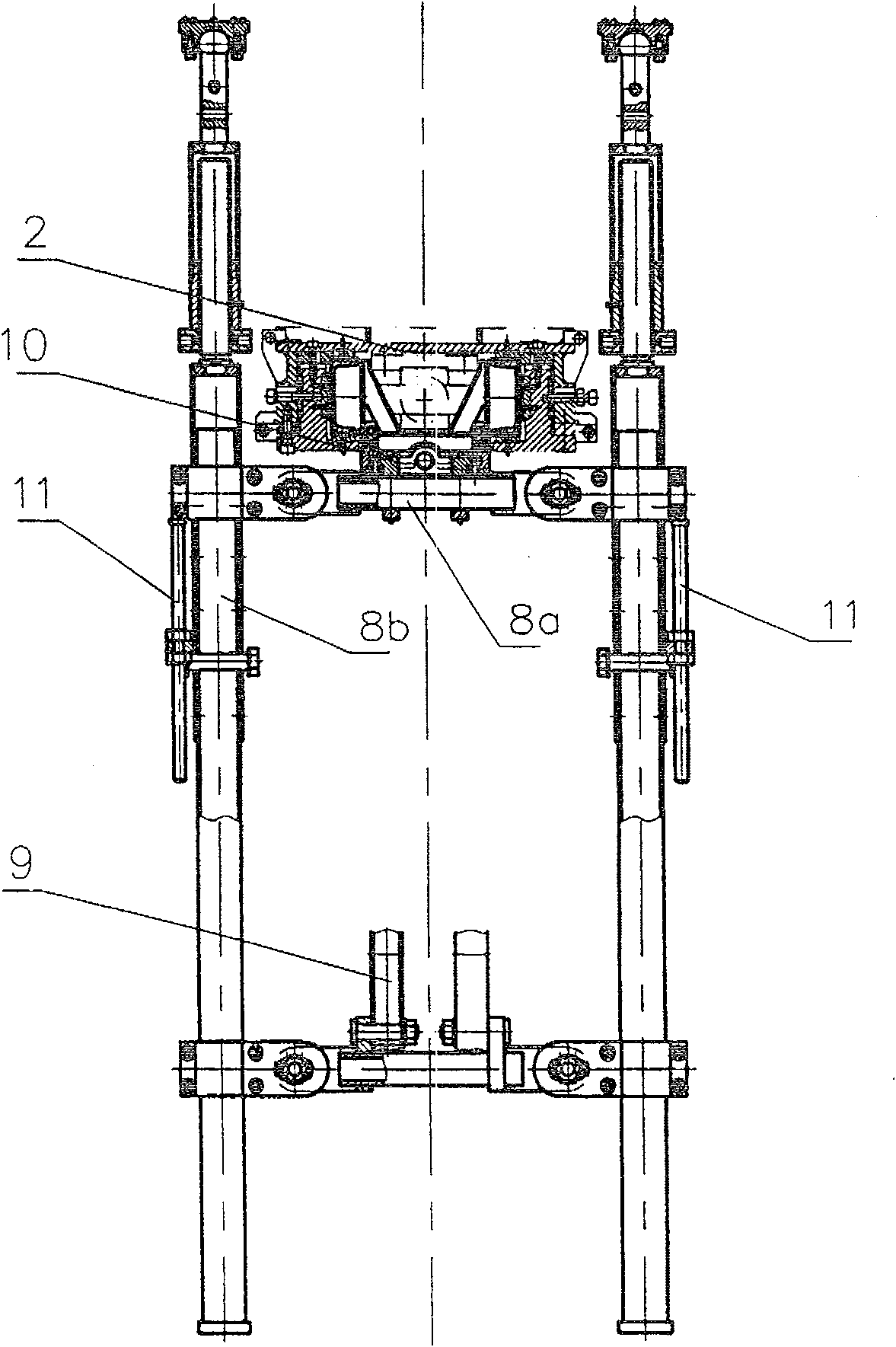

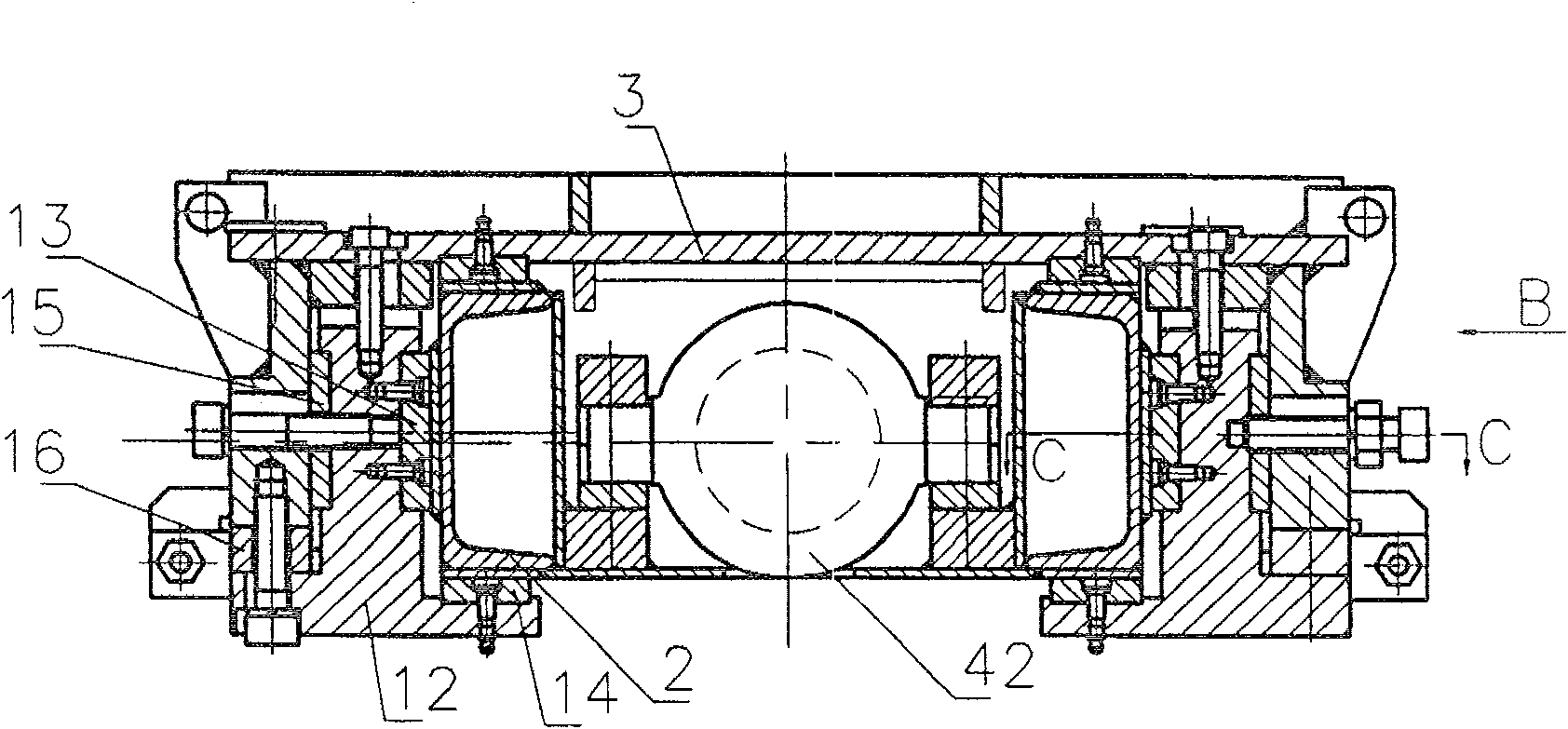

[0020] Such as Figure 1 to Figure 5 As shown, the fully hydraulic gas pumping and discharging multifunctional drilling rig of the present invention has a power head 1, a frame 2, a carriage 3, a chuck 4, a braid 5, a drill pipe 6, a clamper 7, a column frame 8 and a support The rod 9 and the column frame 8 are composed of two left and right columns 8b and a beam 8a. The power head 1 is limited on the guide rail of the frame 2 by the carriage 3. The frame 2 is positioned on the column frame 8 and the support rod 9. The power head 1 The output end is connected with the drill pipe 6 through the chuck 4 and the water braid 5. The frame 2 is connected with the beam 8a of the column frame 8 through the screw nut mechanism 10, and the two ends of the beam 8a of the column frame 8 are connected on the column 8b through the screw nut mechanism 11. The support rod 9 is composed of three sections, and the middle section 9b is Adjust the screw mandrel, and the other two sections 9a, 9c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com