Locking type monkey spanner

A technology of live-end wrench and wrench, which is applied in the direction of wrench, manufacturing tools, wrench, etc., which can solve the problems that the screw mouth cannot be fixed at one time, the equipment assembly is not tight, and the disassembly does not require force, so as to achieve a simple, compact and practical structure. The effect of high reliability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

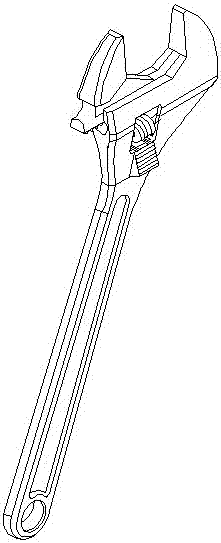

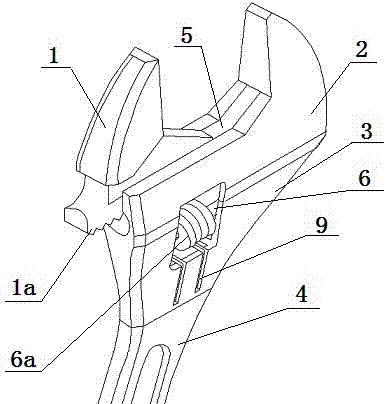

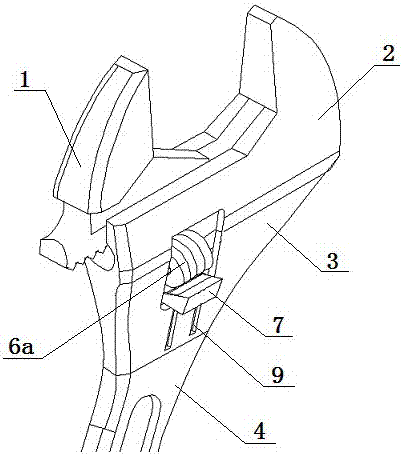

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a locking type adjustable wrench includes a wrench body, a movable wrench 1 and a locking device. The front end of the wrench body is a fixed wrench 2, and the rear end of the wrench body is an operating handle 4. The fixed wrench and the operation The handles are connected via the connecting neck 3, the upper end surface of the connecting neck 2 is provided with a concave chute 5, the side of the connecting neck is provided with an insertion hole 6, and a worm 6a is provided in the insertion hole. The inlet hole extends upwards to the concave chute 5 of the wrench, and the concave chute is equipped with a gap communicating with the insertion hole. The lower end surface of the movable wrench 1 is provided with a slide bar 1a with teeth. The mouth is embedded in the concave chute 5 of the neck th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com