Nano superhydrophobic coating additive and its preparation method and application

A technology of super-hydrophobic coatings and additives, applied in the direction of anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve problems such as difficult promotion and application, high equipment requirements, and high cost, so as to improve hydrophobic performance, simplify the preparation process, and prepare methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A preparation method for nano superhydrophobic paint additive, comprising the following steps:

[0066] Step 1, 10 mg of nanomaterials and 10 mL of solvent are ultrasonically mixed for 8 minutes to obtain solution A, wherein the concentration of nanomaterials in solution A is 1 mg / mL, the nanomaterials are carbon nanotubes, and the solvent is dimethyl sulfoxide;

[0067] Step 2, add catalyst and low surface energy coupling agent to solution A, obtain solution B, use magnetic stirrer to stir solution B for 80min to stir evenly, obtain product C, wherein, catalyst is acetic acid, low surface energy coupling agent is methyltriethoxysilane, the ratio of the mass fraction of the nanomaterial, the volume fraction of the catalyst, and the volume fraction of the low surface energy coupling agent is 500:0.1:10;

[0068] In step 3, the product C is subjected to solid-liquid separation, and the obtained solid is a nano-superhydrophobic coating additive, and the solid-liquid separa...

Embodiment 2

[0084] A preparation method for nano superhydrophobic paint additive, comprising the following steps:

[0085] Step 1, 100 mg of nanomaterials and 100 mL of solvent are ultrasonically mixed for 10 minutes to obtain solution A, wherein the concentration of nanomaterials in solution A is 1 mg / mL, the nanomaterials are carbon nanotubes, and the solvent is dimethyl sulfoxide;

[0086] Step 2, add catalyst and low surface energy coupling agent to solution A, obtain solution B, use magnetic stirrer to stir solution B for 80min until stirring evenly, obtain product C, wherein, catalyst is hydrochloric acid, low surface energy coupling agent is methyltrichlorosilane, the ratio of the mass fraction of the nanomaterial, the volume fraction of the catalyst, and the volume fraction of the low surface energy coupling agent is 500:0.5:10;

[0087] In step 3, the product C is subjected to solid-liquid separation, and the obtained solid is a nano-superhydrophobic coating additive, and the sol...

Embodiment 3

[0092] A preparation method for nano superhydrophobic paint additive, comprising the following steps:

[0093] Step 1, 10 mg of nanomaterials and 10 mL of solvent are ultrasonically mixed for 8 minutes to obtain solution A, wherein the concentration of nanomaterials in solution A is 1 mg / mL, and the nanomaterials are SiO 2 , the solvent is xylene;

[0094] Step 2, add catalyst and low surface energy coupling agent to solution A, obtain solution B, use magnetic stirrer to stir solution B for 80min until stirring evenly, obtain product C, wherein, catalyst is hydrochloric acid, low surface energy coupling agent It is dodecyltrimethoxysilane, and the ratio of the mass fraction of the nanomaterial, the volume fraction of the catalyst, and the volume fraction of the low surface energy coupling agent is 500:1:10;

[0095] In step 3, the product C is subjected to solid-liquid separation, and the obtained solid is a nano-superhydrophobic coating additive, and the solid-liquid separat...

PUM

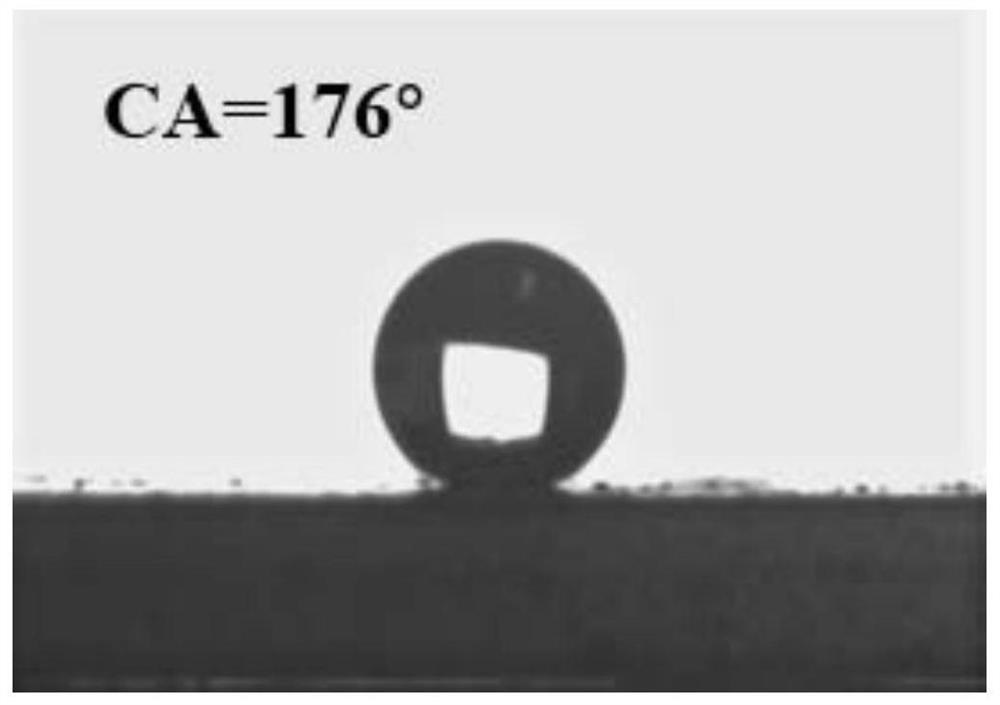

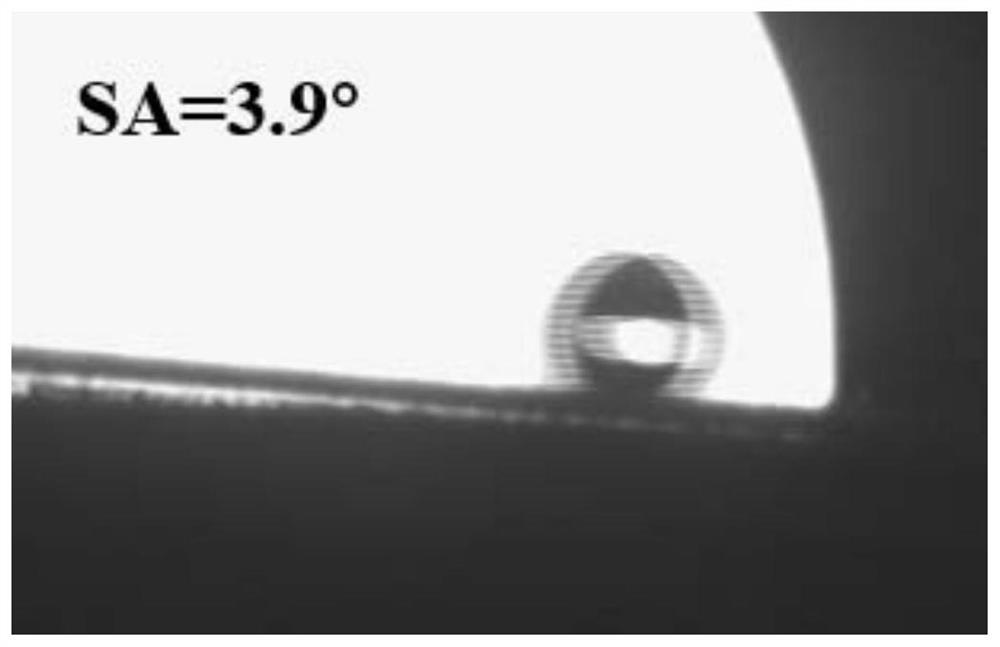

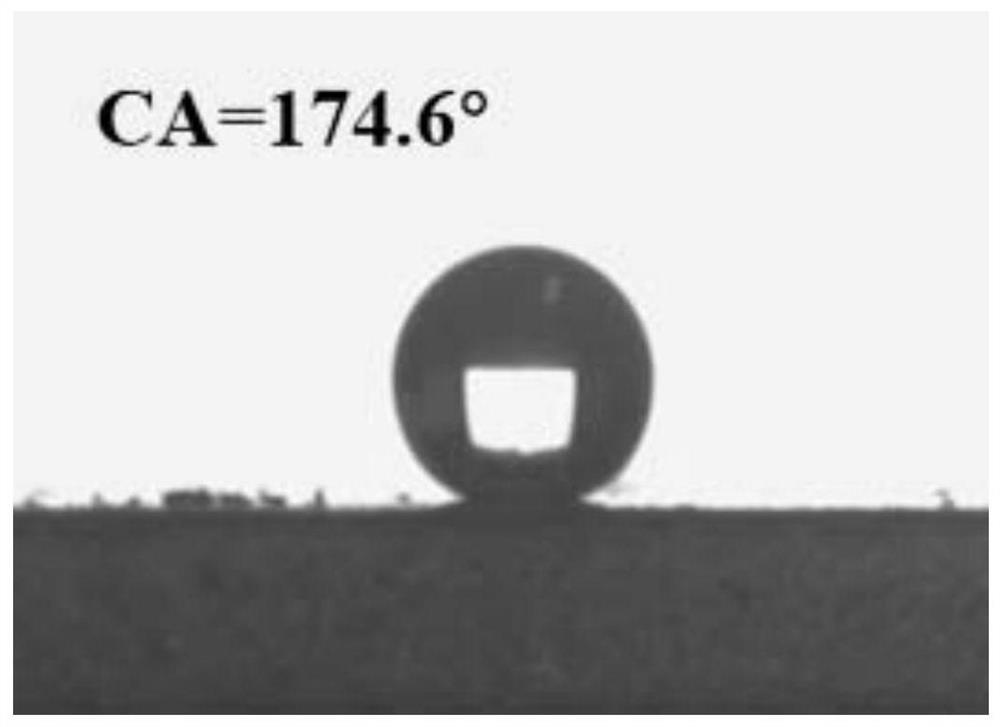

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com