Safety detection method of underwater stage light inner plate

A technology for safety testing and stage lights, applied in the direction of mechanical solid deformation measurement, etc., can solve the problems of difficult removal of the board, damage to the sealing of the light body, and difficult testing, and achieve the effect of easy execution and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

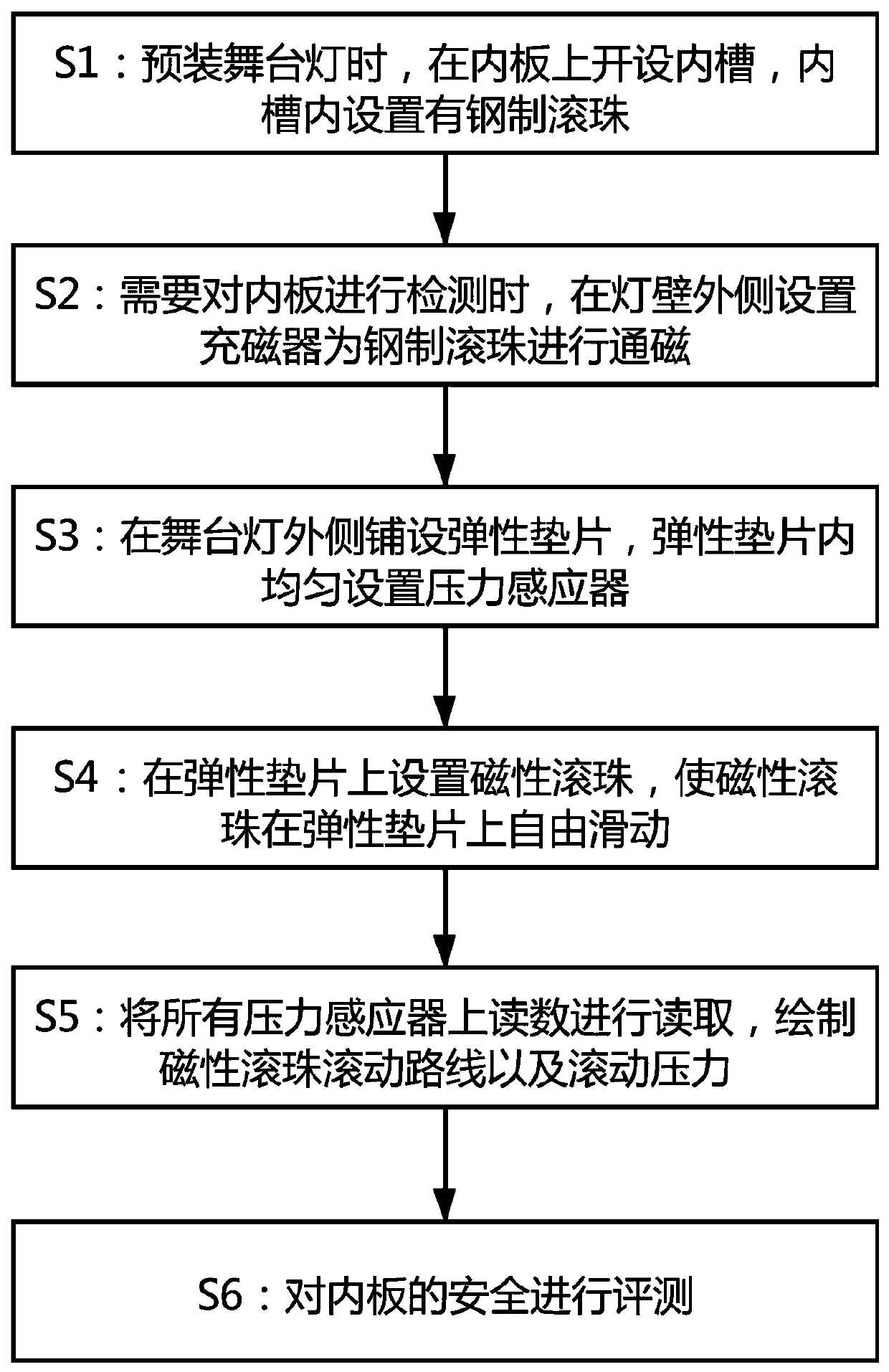

[0033] Such as figure 1 As shown, it is only one of the embodiments of the present invention. The present invention provides a safety detection method for the inner panel of the underwater stage lamp. The method includes the following steps:

[0034] S1: When the stage light is pre-installed, an inner groove is set on the inner plate, and steel balls are arranged in the inner groove;

[0035] When the manufacturer installs the multi-layer structure of the stage light, an inner groove is set on the inner plate, and a steel ball is set in the inner groove. After leaving the factory, any inspection of the inner plate does not need to disassemble and open the internal structure of the lamp body, ensuring The tightness of the stage light body.

[0036] Of course, at least one inner groove is opened on the inner plate, and the extension track of the inner groove is recorded. It is best to set inner grooves at the edge of the inner plate and at the axis, and then record the distrib...

Embodiment 2

[0055] still as figure 1 As shown, it is still one of the embodiments of the present invention. In order to make the safety detection method of the underwater stage lamp inner panel of the present invention more convenient to control and have higher detection accuracy, the present invention also has the following designs :

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com