Charging head shell injection molding machine discharge mechanism

A technology of injection molding machine and charging head, applied in the field of blanking mechanism, can solve problems such as low efficiency, complex structure, and difficulty in taking out workpieces, and achieve the effects of simple structure, improved adaptability, and strong locking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

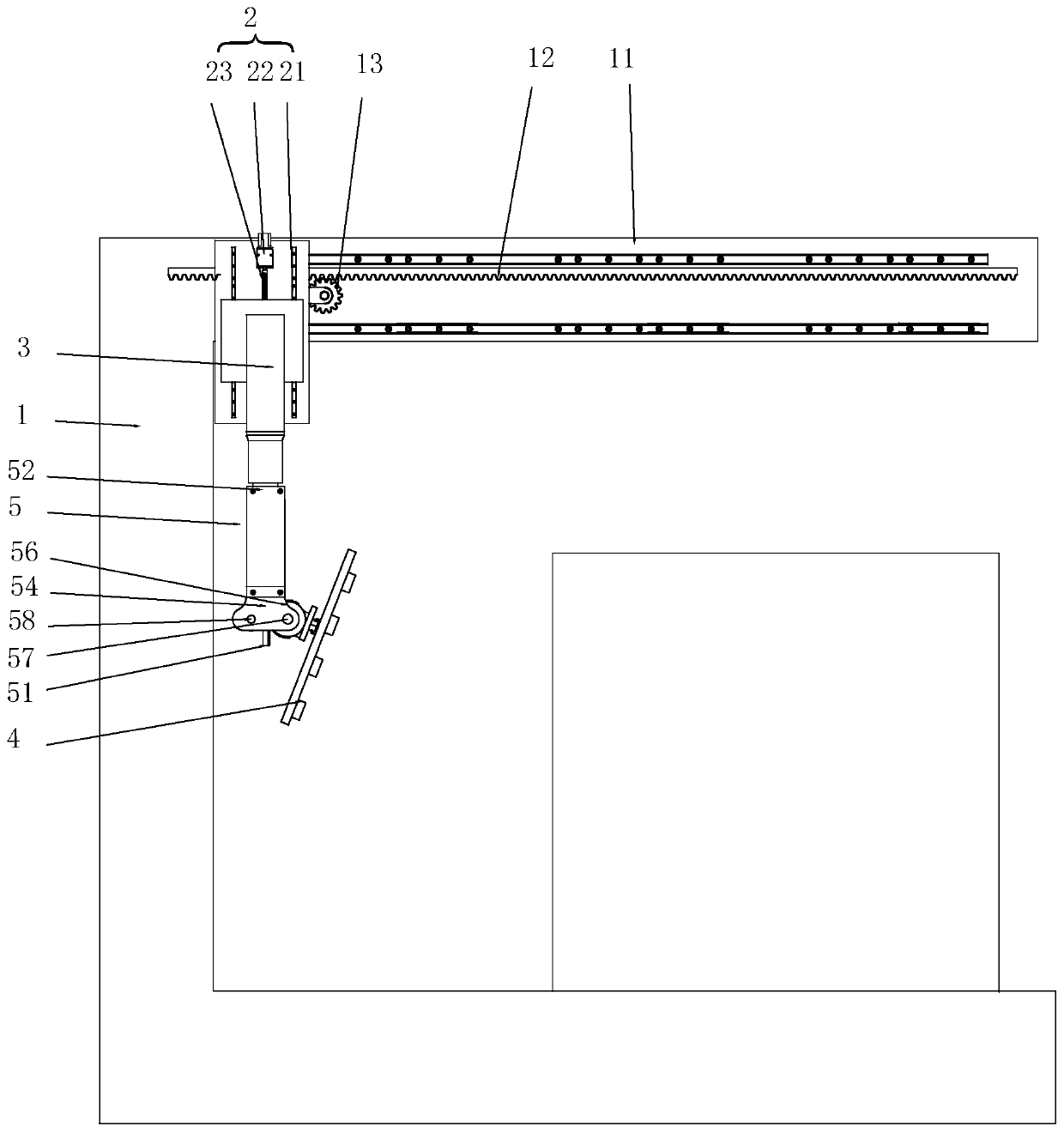

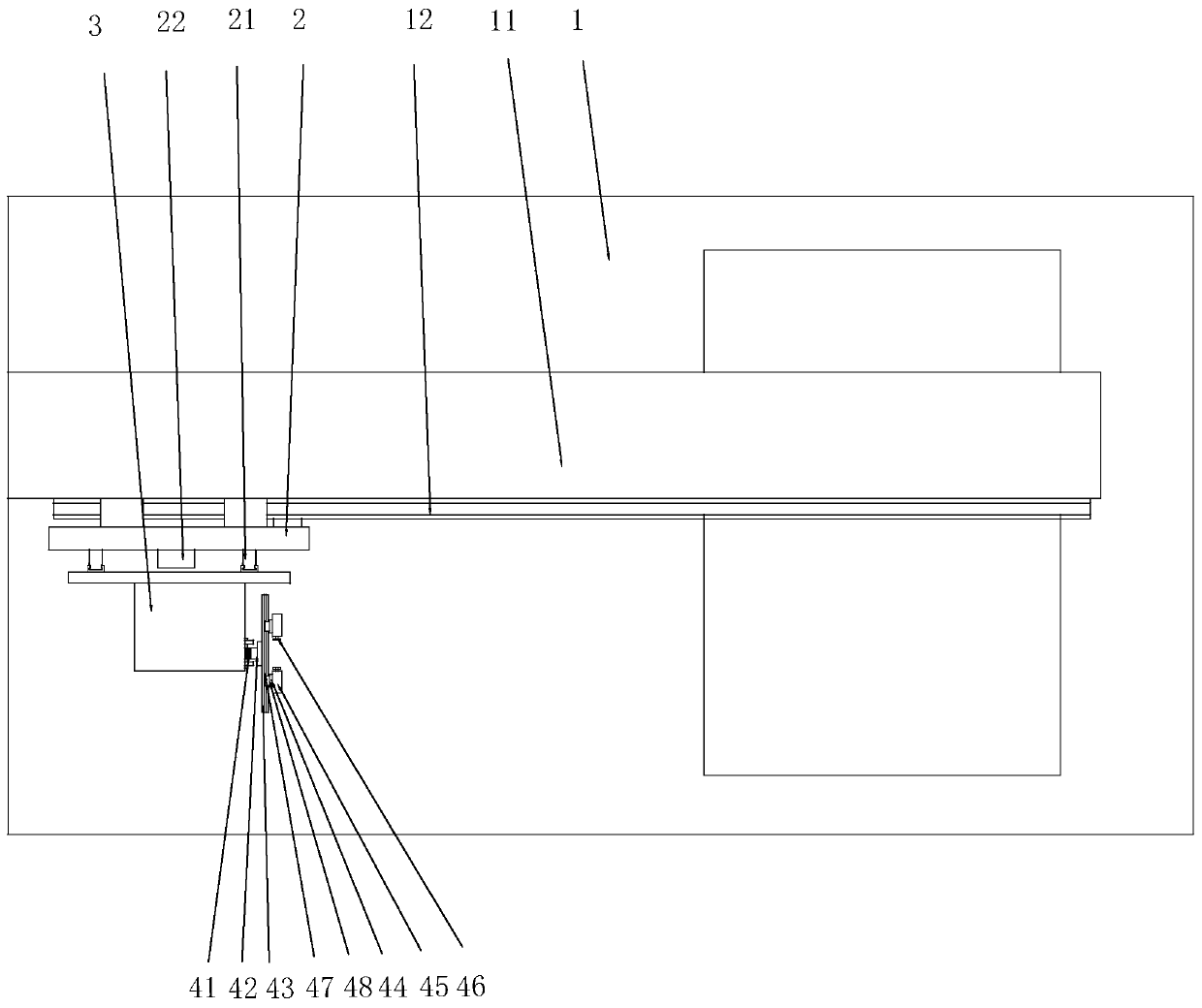

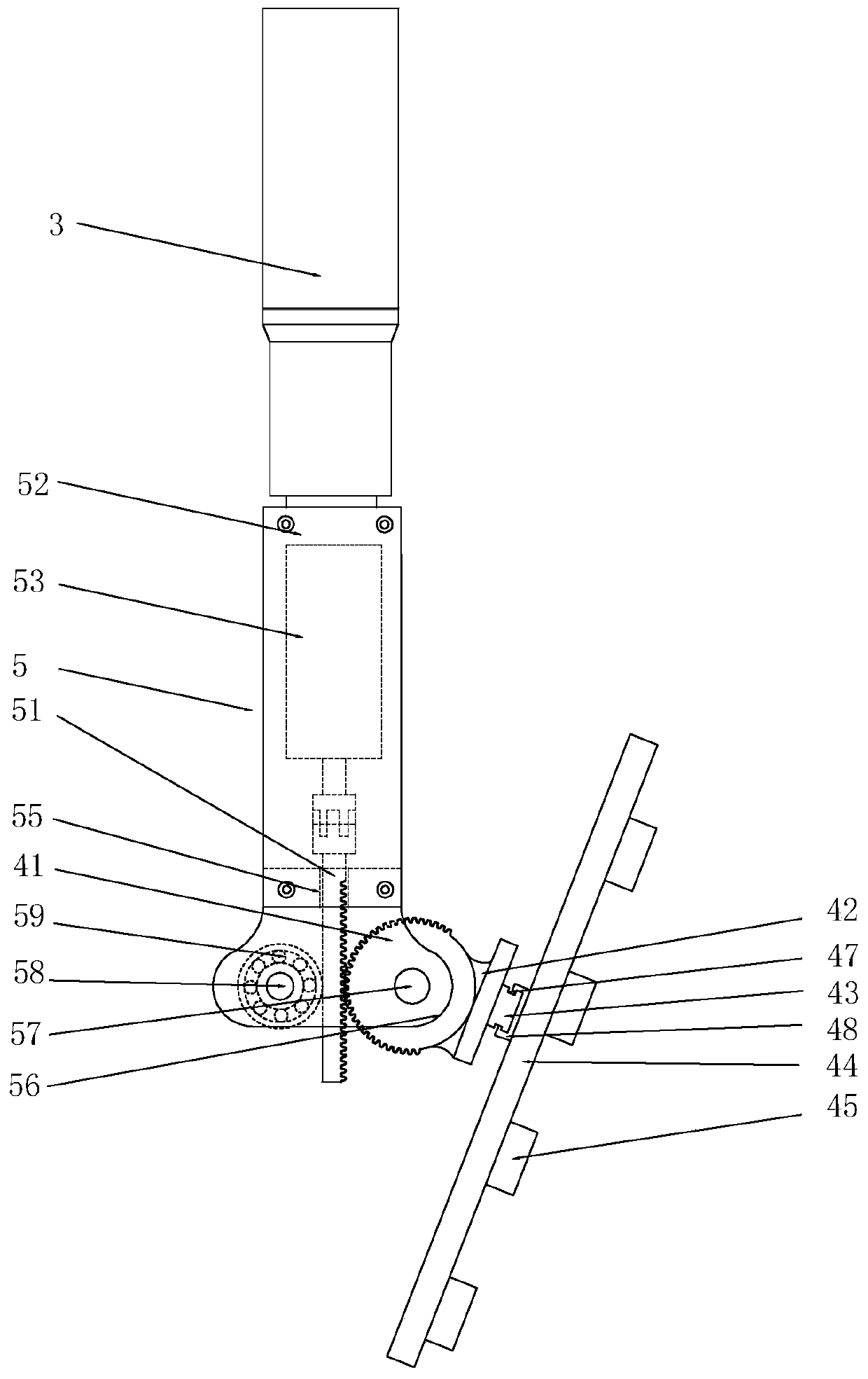

[0026] see Figure 1 to Figure 6 , The invention provides an injection molding machine for a charging head shell, including a charging head shell injection molding machine blanking mechanism. Among them, the charging head casing injection molding machine blanking mechanism includes a frame 1, a sliding seat 2 slidably arranged on the frame 1, a rotating arm 3 that can be lifted and lowered on the sliding seat 2, and a flip clamp 4 for clamping workpieces ; The overturning clamp 4 is rotatably arranged at the end of the rotating arm 3, and the rotating arm 3 is provided with an angle adjustment mechanism 5 for adjusting the turning angle of the overturning clamp 4. It can be seen that the unloading mechanism in this application has at least a four-axis structure, which can meet the problem of multi-angle retrieving.

[0027] In order to realize the above-mentioned actions, a cross rail beam 11 is arranged on the frame 1, and the sliding seat 2 is slidably installed on the cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com