Aviation hole-forming robot end effector capable of adjusting attitude

An end-effector, attitude technology, applied in the direction of manufacturing tools, boring/drilling, drilling/drilling equipment, etc., can solve problems such as staying, and achieve the effect of improving greening, ensuring quality and accuracy, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings.

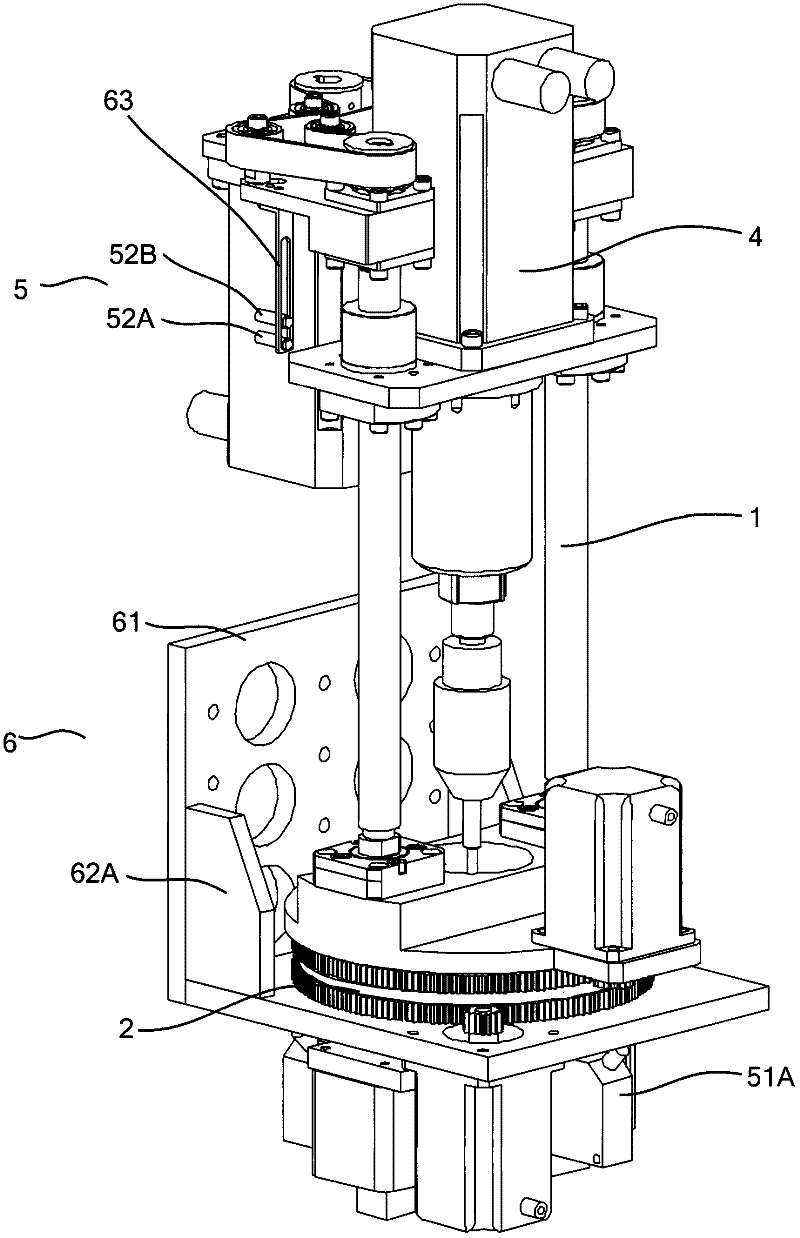

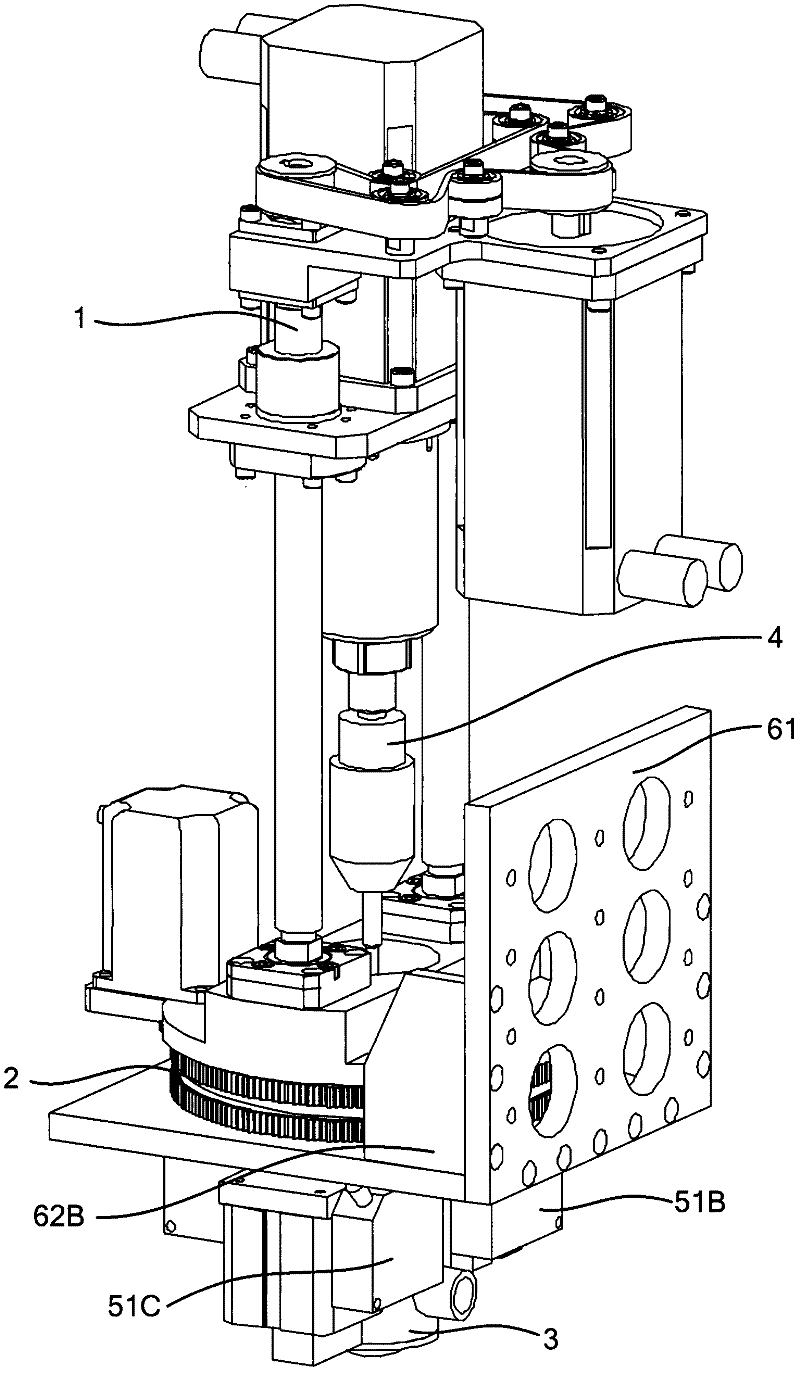

[0052] See Figure 1A , Figure 1B The invention consists of five modules: a screw feed module 1, a binary angle adjustment mechanism 2, a compacting and sucking module 3, a drilling module 4, and a sensor module 5. The system needs to return to zero before drilling; then the laser ranging sensor in the sensor module 5 measures the normal vertical to the hole-making point; the binary angle adjustment mechanism 2 adjusts the posture of the end of the actuator; the chip suction module 3 is compressed The aircraft skin is compressed, and the dust suction device is turned on; the screw feed module 1 drives the drilling module 4 to make holes on the aircraft skin.

[0053] (1) Lead screw feed module

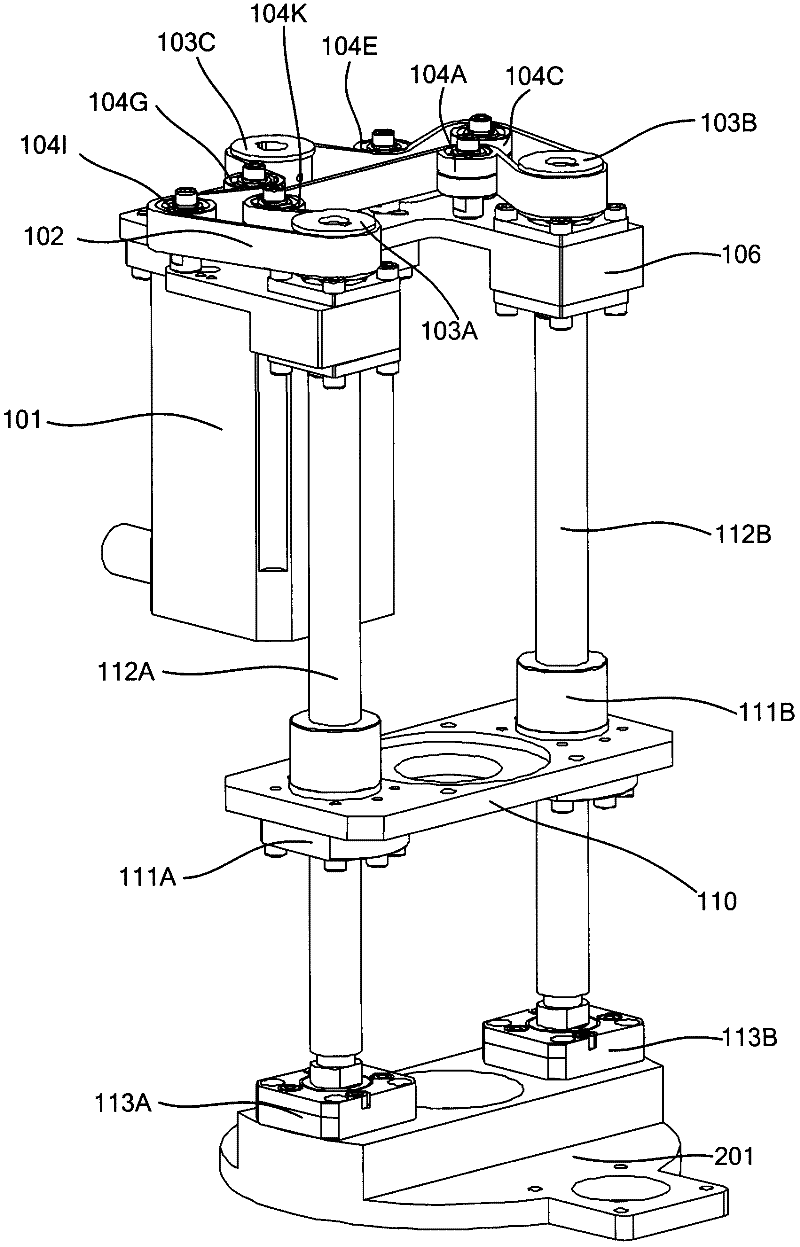

[0054] See Figure 2A with Figure 2B As shown, the screw feed module 1 includes: a screw drive motor 101, a timing belt 102, pulleys 103A to C, rolling bearings 104A to L,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com