Speed changing tool and speed changing control method thereof

A technology of a speed change tool and a control unit, which is applied in the field of speed change control of this type of speed change tool, can solve the problems such as the inability to truly realize the industrialized implementation of automatic shifting and the complex mechanical structure of the gear transmission mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

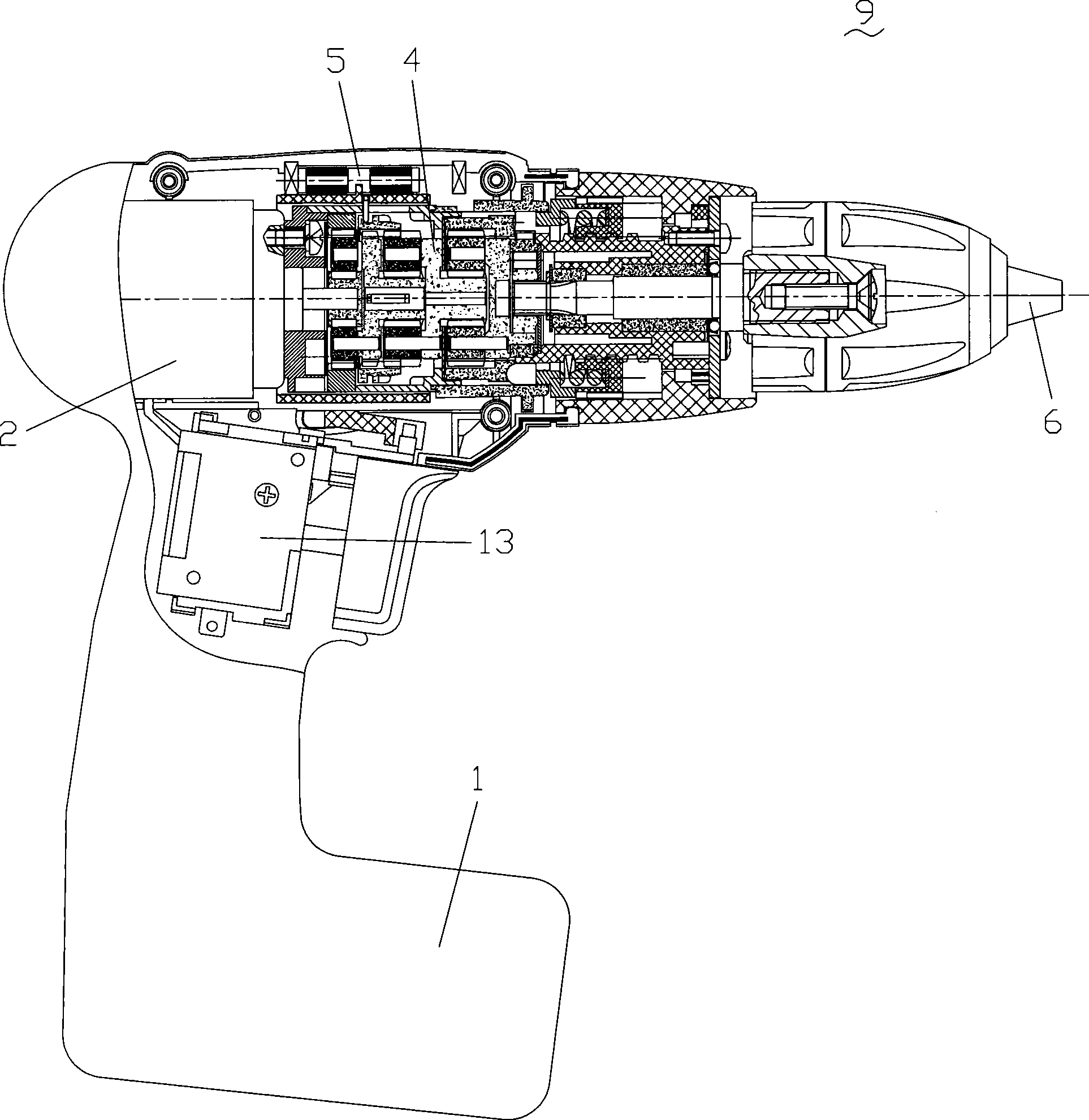

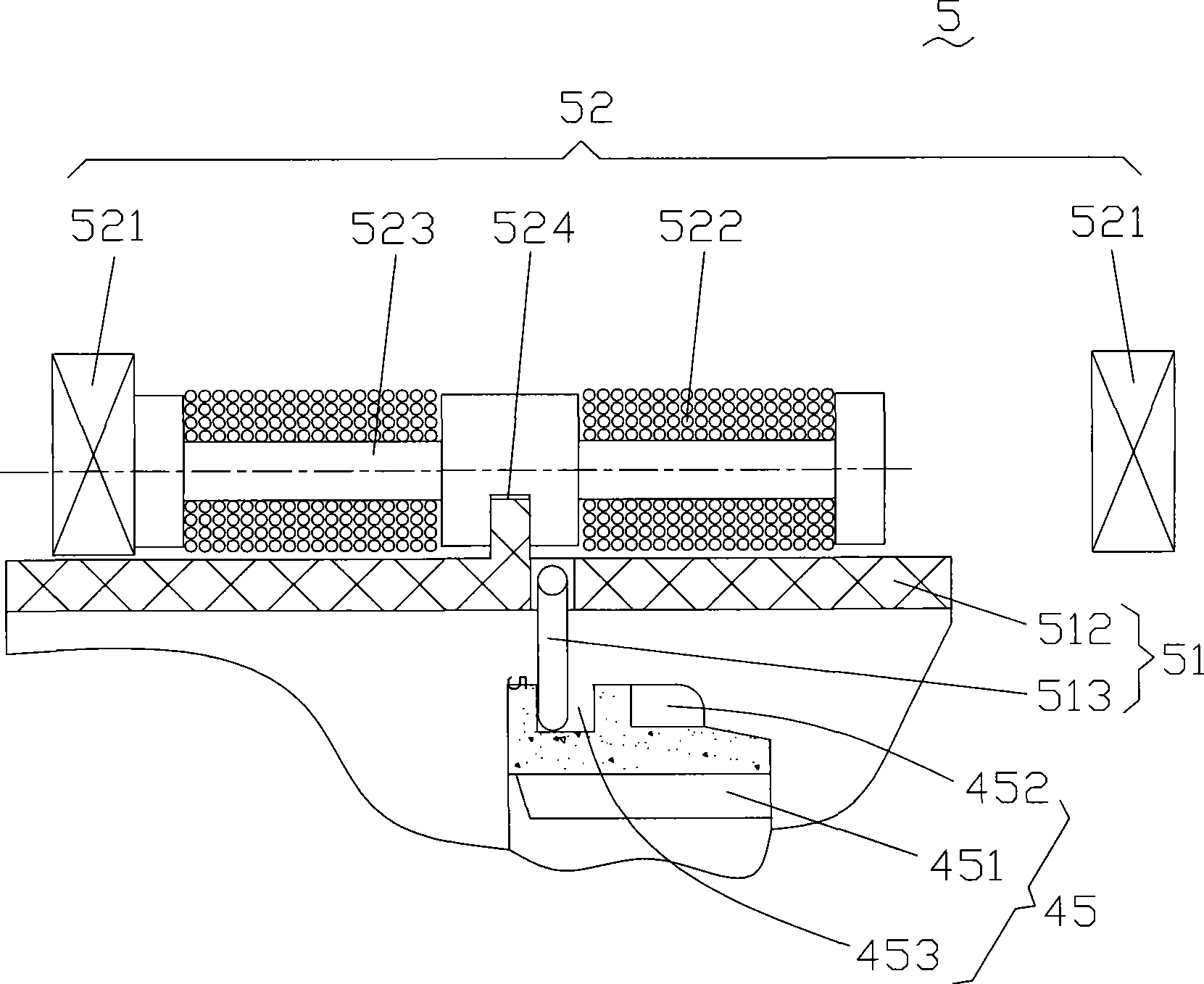

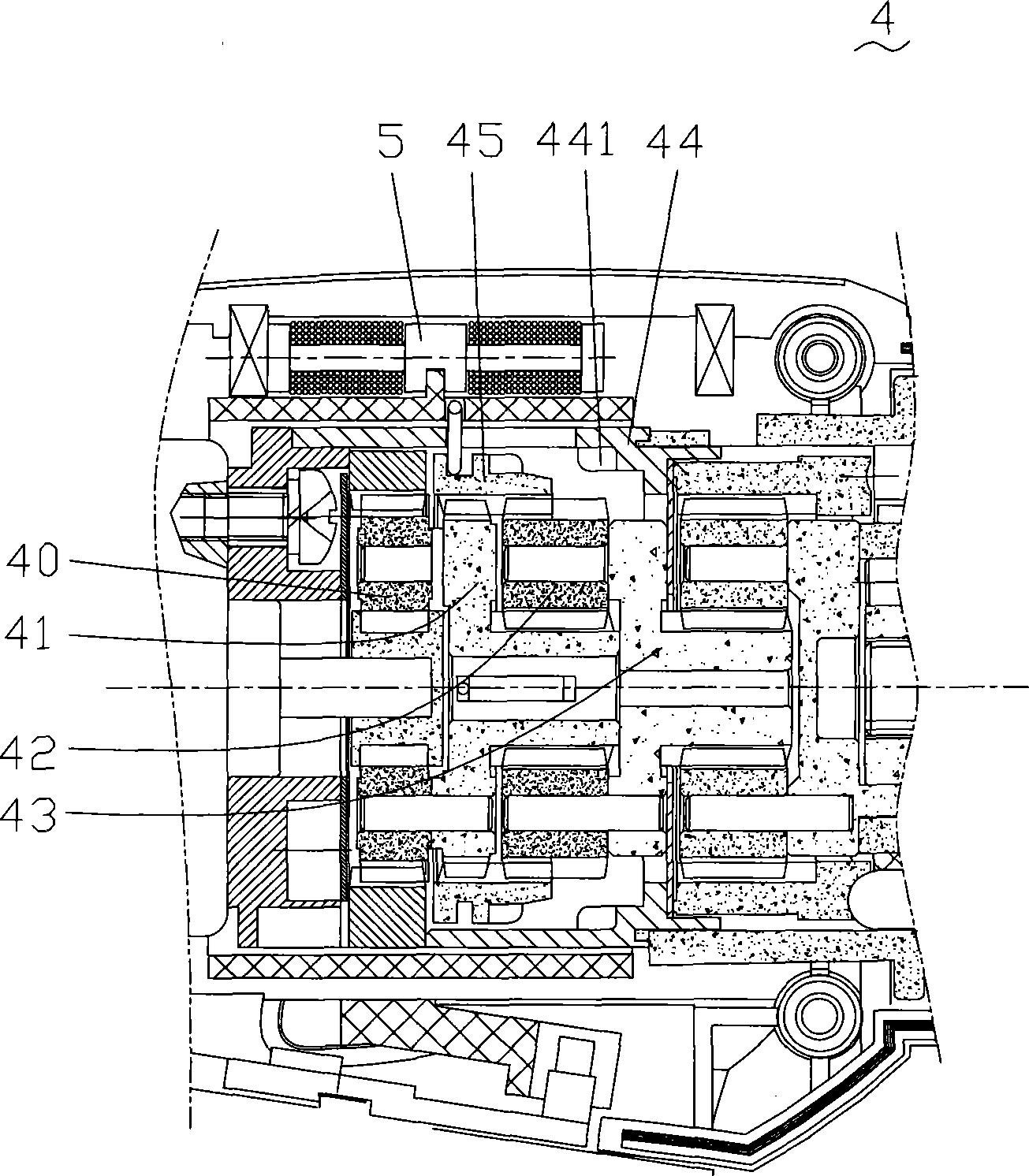

[0038] Reference Figure 1 to Figure 3b Shown is a schematic structural diagram of the first embodiment of the driving device of the variable speed tool control system of the present invention. A variable speed tool 9 includes a motor 2, a motor power supply 1, a main switch 13 for starting / stopping the motor, an output shaft 6, and a gear transmission mechanism 4. The gear transmission mechanism 4 includes a first planetary gear set consisting of a first planetary gear 40 and a first planet carrier, and a second planetary gear set consisting of a second planetary gear 42 and a second planet carrier 43, which are fixedly arranged in the tool housing The upper rotation stop device 44 and the movable member 45 that can move axially. The driving device 5 is arranged on the gear transmission mechanism 4, and includes a driving part 52 and a transmission part 51. The driving part of this embodiment adopts an electromagnet device, which includes two permanent magnets 521 spaced apart at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com