Method for preparing silica aerogel material

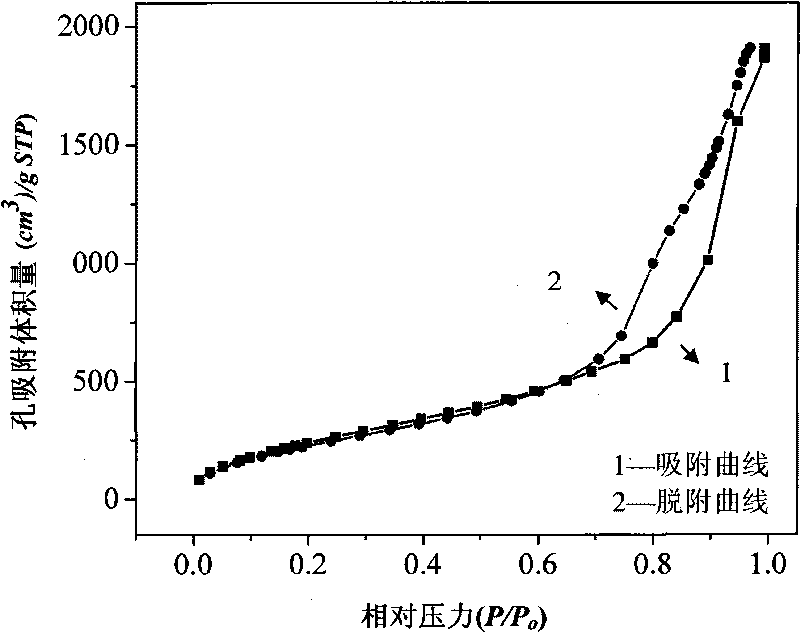

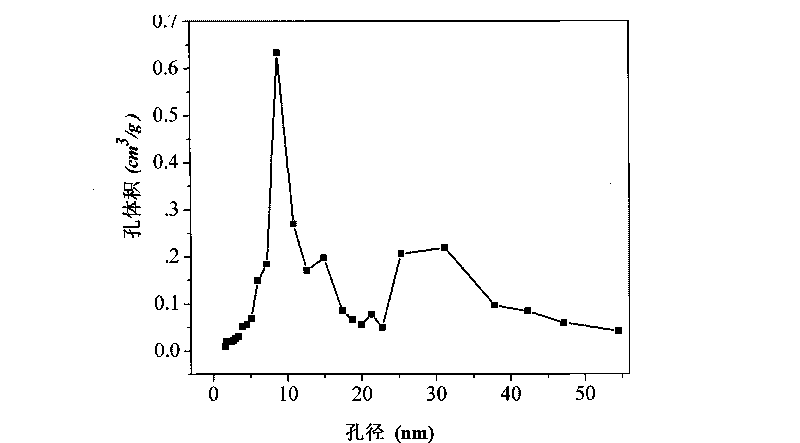

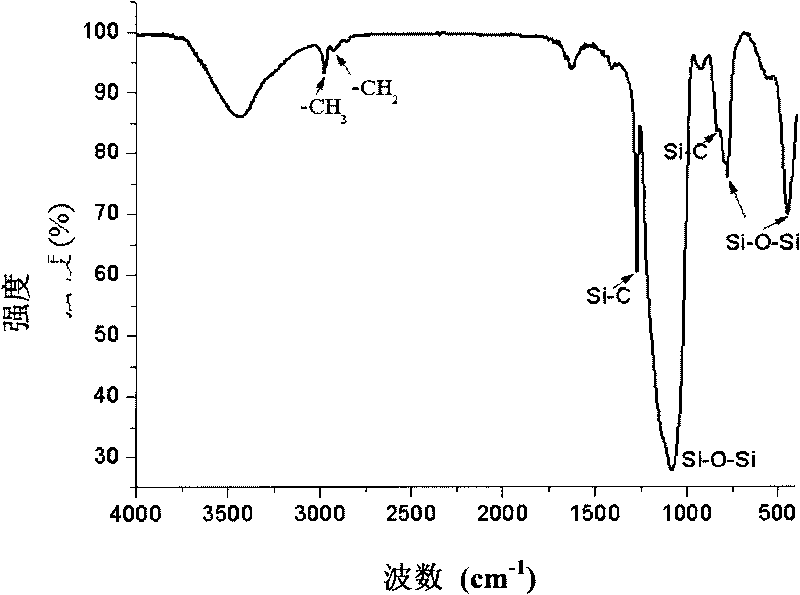

A silicon dioxide and aerogel technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of long preparation cycle and the preparation process route needs to be optimized, and achieve low density, good hydrophobicity, and concentrated pore size distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The molar ratio of raw materials is TEOS:EtOH:MTMS:H 2 O=1:10:0.3:8, mix 5.5ml of TEOS and 14.4ml of absolute ethanol into the container and start stirring, then add 1.4ml of MTMS modifier, continue stirring, and slowly add 4.5ml of Distilled water, after another 10 minutes of stirring, add hydrochloric acid alcohol solution dropwise, adjust the pH value, so that the pH value of the solution is between 1.5 and 2.0; after stirring continuously for 8 hours, slowly add a certain amount of ammonia water and alcohol solution, so that the final pH value of the system is between 7.5 and 2.0 8.0. Stop stirring after 10min, put SiO 2 The sol was poured into the mold and left to stand for about 1 hour until the sample gelled. After the gel is formed, soak the wet gel in an ethanol solution and let it stand for aging. The aging temperature is 55°C and the aging time is 5h; The ratio by volume is: TMCS:EtOH:n-hexane=1:1:8; modified under sealed conditions for 1-2 days. After mod...

Embodiment 2

[0051] The molar ratio of raw materials is TEOS:EtOH:MTES:H 2 O=1:10:0.4:6, mix 5.5ml of TEOS and 14.4ml of absolute ethanol into the container and start stirring, then add 2ml of MTES modifier, continue stirring, and slowly add 2.7ml of distilled water after 15min After stirring evenly, add hydrochloric acid alcohol solution dropwise, and adjust the pH value at about 2.0; after continuous stirring for 8-10 hours, slowly add a certain amount of ammonia water alcohol solution, so that the final pH value of the system is about 8.0. After a few minutes, the stirring was stopped, and the SiO 2 The sol was poured into the mold and left to stand for about 1 hour until the sample gelled. The wet gel was soaked in ethanol solution for aging, the aging temperature was 50°C, and the aging time was 6h; after aging, the gel was soaked in the secondary mixed modification solution, and the composition of the secondary modification solution was: TMCS: Absolute ethanol: n-hexane = 2:3:15; m...

Embodiment 3

[0054] The molar ratio of raw materials is TEOS:EtOH:MTMS:H 2 O=1:10:0.3:10, mix 5.5ml of TEOS and 14.4ml of absolute ethanol into the container and start stirring, then add 1.1ml of MTMS modifier, continue stirring, and slowly add 3.6ml of Distilled water, after another 15 minutes, evenly add dilute alcohol solution of hydrochloric acid, adjust the pH value of the solution at 1.5-2.0; The final pH value of the system is 7.5-8.0. Stop stirring after 10 minutes, and SiO 2 The sol was poured into the mold and left to stand for about 1 hour until the sample gelled. After the gel is formed, add a small amount of ethanol to the mold to age the gel soaked in ethanol, and age at 60°C for about 6 hours; then use the prepared secondary modification solution for sealing modification, and the ratio of the modification solution is as follows The volume ratio is TMCS: absolute ethanol: n-hexane = 1:1:8; after about 2 days of modification, the sample is taken out and washed with n-hexane,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com