Preparation method of grapheme or doped graphene or graphene complex

A graphene and composite technology, applied in the field of carbon material preparation, can solve the problems of difficulty in preparing graphene products in large quantities, small, generally only tens to hundreds of nanometers, limited specific surface area, etc., to achieve the effect of convenient batch preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a method for preparing graphene, doped graphene or graphene composite, which uses lamellar natural compounds to prepare graphene, doped graphene or graphene by vapor phase chemical deposition method or liquid phase impregnation method. Graphene composite. The lamellar natural compound is one or a mixture of kaolin, montmorillonite, vermiculite, mica, brucite and pseudo-boehmite.

[0021] In the preparation method of graphene, doped graphene or graphene composite of the present invention, the reaction temperature of the vapor phase chemical deposition method is 300°C to 1000°C, preferably 600°C to 900°C; The deposition method uses one or more mixtures of nitrogen, argon and helium as the carrier gas; uses methane, ethane, ethylene, acetylene, propane, propylene, butane, liquefied petroleum gas and carbon monoxide One or more mixtures are used as carbon source gas, such as preferably methane or ethylene; one or more mixtures of ammonia (NH3), dibor...

Embodiment 1

[0051] Weigh 20g of vermiculite and put it into a vertical fluidized bed reactor with a diameter of 50mm. The reactor is operated under normal pressure conditions, and the temperature is raised to 900°C under 0.2L / min argon flow, and then 0.6L / min Methane flow reacted for 20 minutes, and the intermediate product was taken out after cooling to room temperature. At 60-90°C, first pickle the intermediate product with hydrochloric acid solution (50% volume concentrated hydrochloric acid+50% volume deionized water); then use hydrofluoric acid solution (50% volume hydrofluoric acid+50% volume deionized water) to pickle the intermediate product to remove the vermiculite; finally wash it to neutral with deionized water and dry it at 80° C. for 12 hours to obtain 0.5 g of the final product.

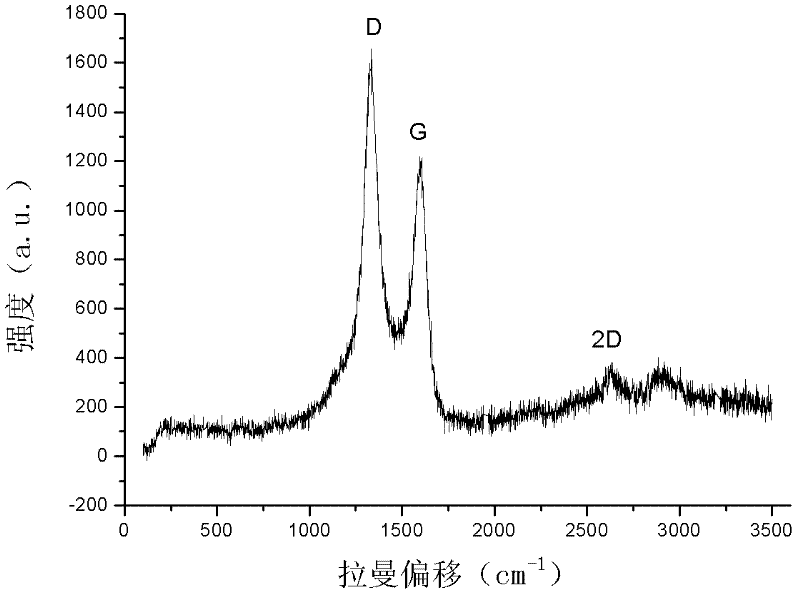

[0052] Thermogravimetric analysis (TGA-2050, air flow 20ml / min, heating rate 10 ℃ / min) shows that carbon component content 97% (mass percentage composition) in the product, Raman spectrum (see fi...

Embodiment 2

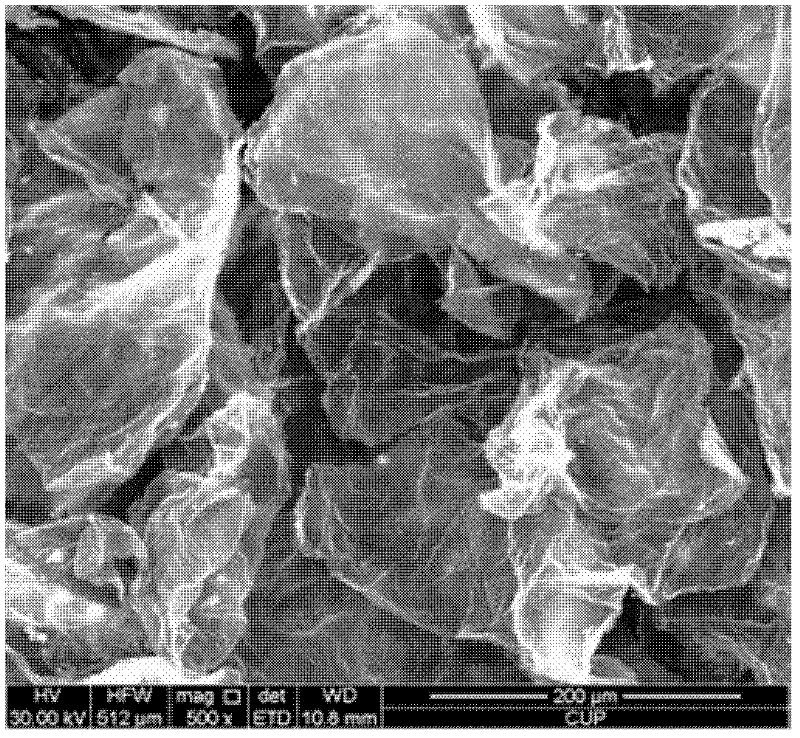

[0054] Using ethylene as the carbon source gas and vermiculite as the template, it can be prepared as image 3 The graphene product shown has flakes up to a few hundred microns in size.

[0055] The preparation process is as follows: Weigh 30g of vermiculite and put it into a vertical fluidized bed reactor with a diameter of 50mm. 0.6L / min ethylene was reacted for 30 minutes, and the intermediate product was taken out after cooling to room temperature. The vermiculite was removed by hydrochloric acid pickling and hydrofluoric acid pickling (the specific method of pickling was the same as in Example 1).

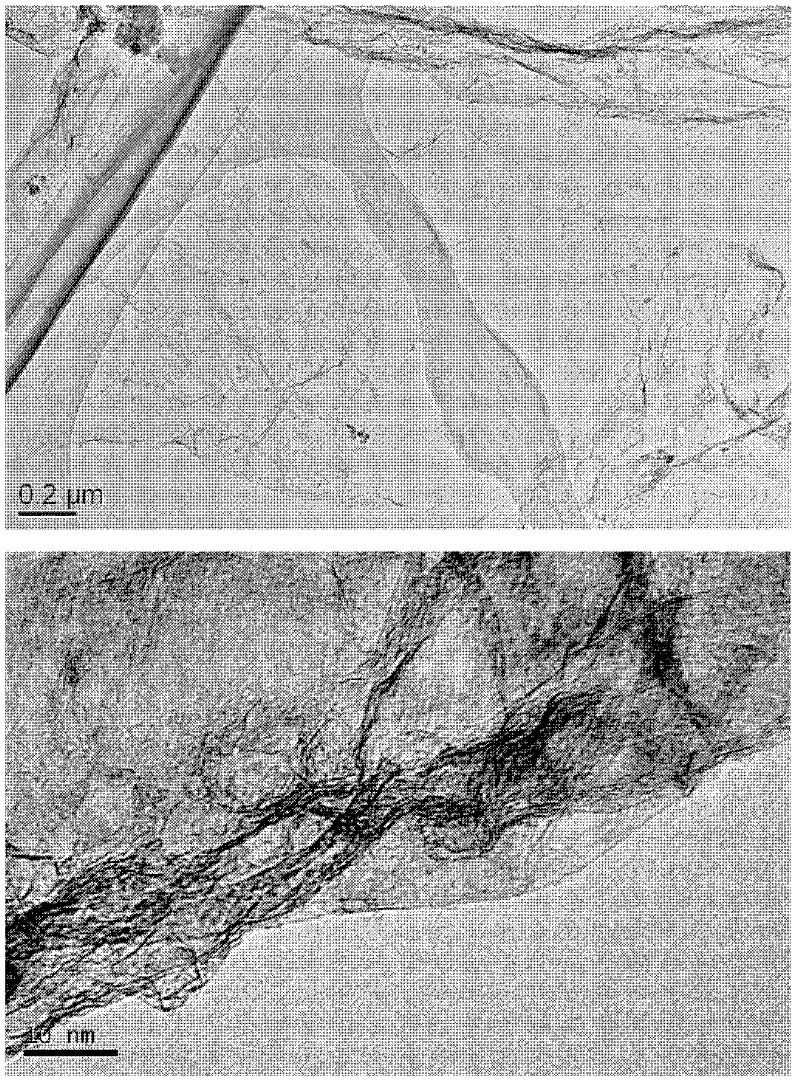

[0056] Thermogravimetric analysis (TGA-2050, air flow 20ml / min, heating rate 10°C / min) shows that the carbon component content is 95% in the product, and the Raman spectrum shows that the sample has the G peak, D peak and 2D peak. Confirm through the observation of transmission electron microscope (JEM2100, JEOL), the graphene product that obtains has the graphite layer str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com