High-performance rare earth permanent magnet sintered magnet and manufacturing method thereof

A technology of sintered magnets and rare earth permanent magnets, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problems of reduced remanence of magnets, difficult use by customers, and great influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

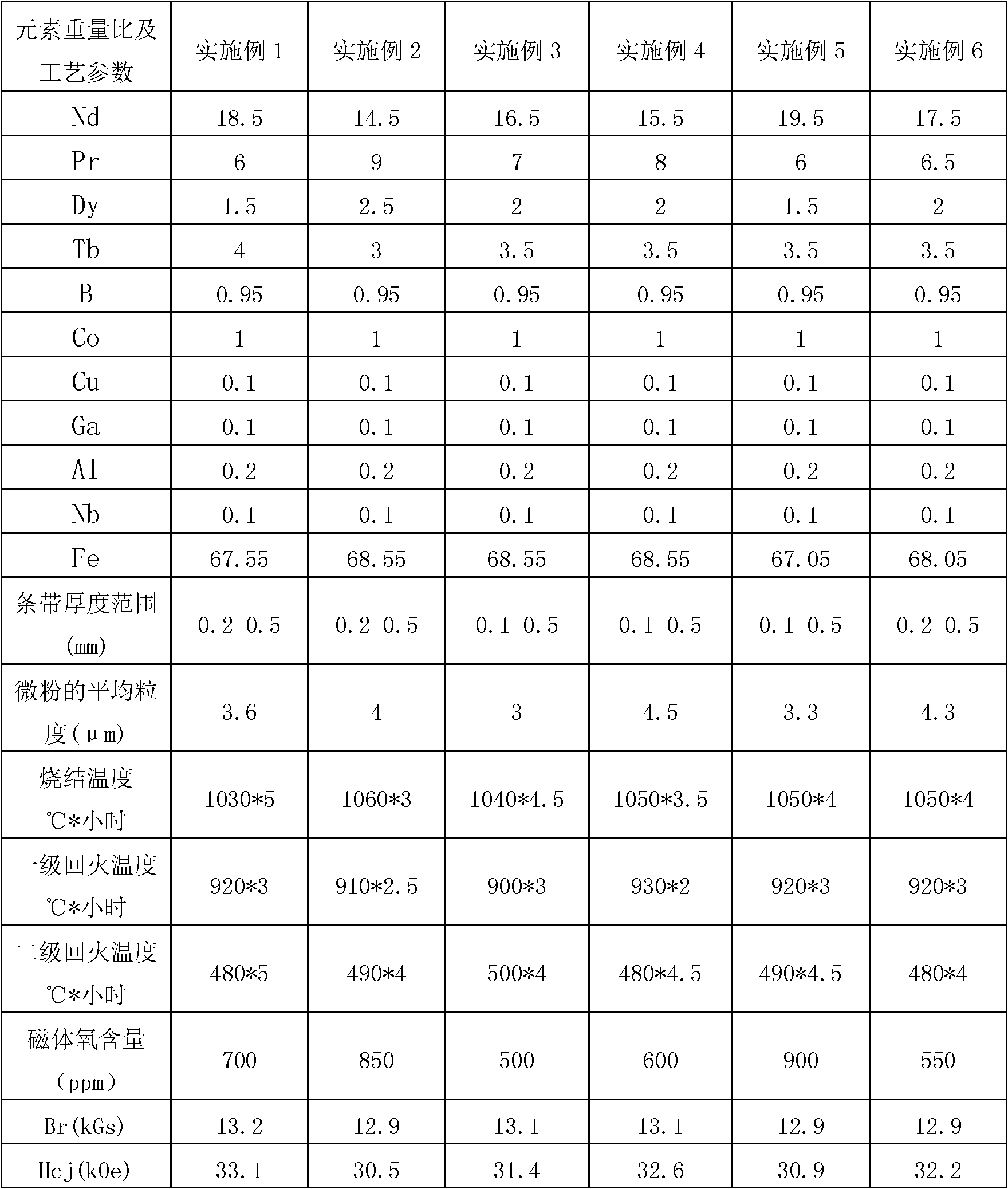

Examples

Embodiment 1

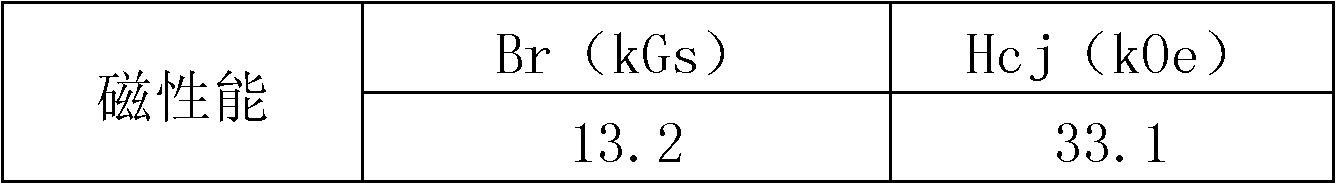

[0021] Table 1 is the composition distribution table of embodiment 1.

[0022] Table 1

[0023] the element

Nd

Pr

Dy

Tb

B

co

Cu

Ga

Al

Nb

Fe

mass percentage

18.5

6

1.5

4

0.95

1.0

0.1

0.1

0.2

0.1

67.55

[0024] Firstly, the ratio of raw materials is carried out according to the composition weight percentage shown in Table 1, and the steel ingot is smelted in a vacuum quick-setting thin slice furnace to produce alloy flakes of 0.2-0.5mm, and the alloy flakes are subjected to hydrogen crushing in a hydrogen crushing furnace, and the hydrogen crushed The powder is ground into a fine powder with an average particle size of 3.6 μm by jet milling. Under the protection of nitrogen, the alloy powder is pressed and formed in an orientation magnetic field. After pressing and formed, it is sintered and aged in a vacuum sintering furnace. The sintering ...

Embodiment 2

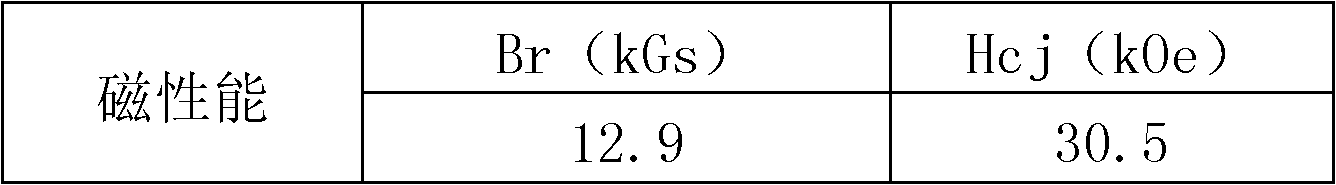

[0029] Table 3 is the composition distribution table of embodiment 2.

[0030] table 3

[0031] the element

Nd

Pr

Dy

Tb

B

co

Cu

Ga

Al

Nb

Fe

mass percentage

14.5

9

2.5

3

0.95

1.0

0.1

0.1

0.2

0.1

68.55

[0032] Firstly, the ratio of raw materials is carried out according to the composition weight percentage shown in Table 3, and the steel ingot is smelted in a vacuum quick-setting flake furnace to produce alloy flakes of 0.2 to 0.5mm. The alloy flakes are hydrogen crushed in a hydrogen crushing furnace, and the hydrogen crushed The powder is ground into a fine powder with an average particle size of 4.0 μm by jet milling. Under the protection of nitrogen, the alloy powder is pressed and formed in an orientation magnetic field. After pressing and formed, it is sintered and aged in a vacuum sintering furnace. The sintering temperature is 1030-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com