High-performance natural silk fiber and preparation method thereof

A natural silk and high-performance technology, applied in fiber processing, animal fiber, textiles and papermaking, etc., can solve the problems of limited performance improvement, poor mechanical properties, and inability to achieve the effect of improving fracture strength and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Prepare natural silk swelling solution: dilute 98wt% formic acid to 80% with water, then add lithium bromide to make 80% formic acid solution containing 2% lithium bromide, which is silk swelling solution;

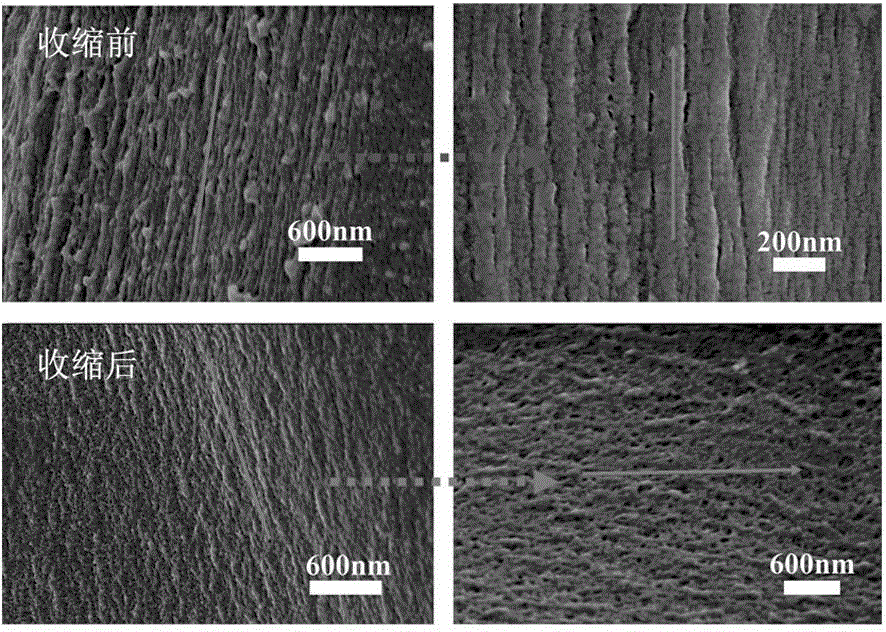

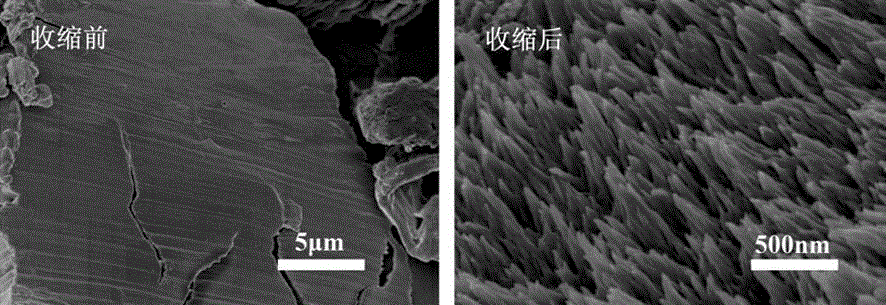

[0030] (2) Submerge the silkworm cocoons in the swelling solution of step (1) for 30 seconds, and at the same time control the shrinkage of the cocoons to 60% of the original length to obtain the shrunk cocoons;

[0031] (3) The shrinkage cocoons obtained in step (2) are washed with deionized water, then neutralized with excess acid in 1wt% sodium hydroxide aqueous solution, washed again, and dried in an oven at 60°C to obtain high-performance natural silk fibers .

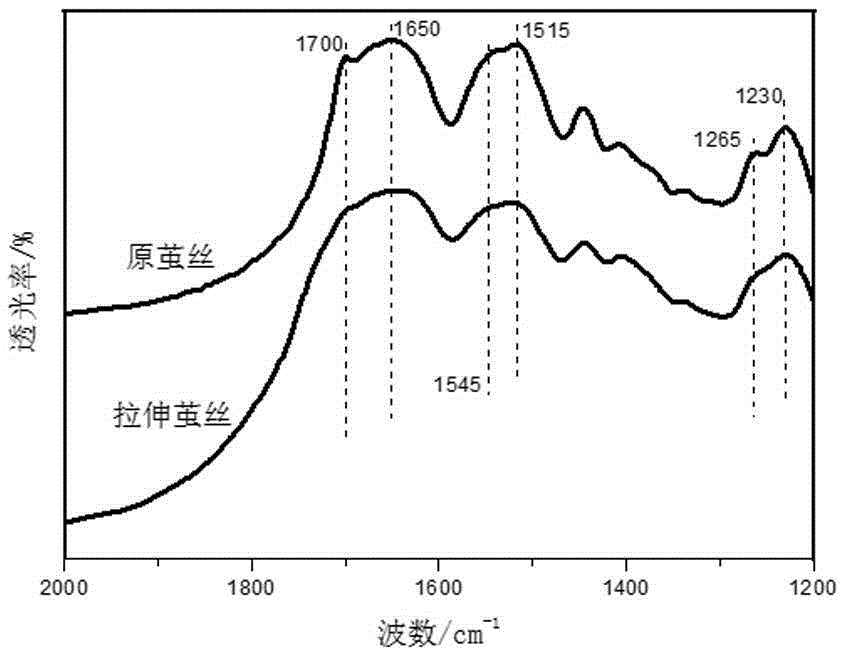

[0032] Table 1 shows the mechanical tensile data of silkworm cocoon silk before and after treatment. The cocoon silk treated according to the technical scheme provided by the present invention has excellent ductility, and the elongation at break reaches more than 50%.

[0033] Table 1 Mechanical te...

Embodiment 2

[0037] (1) Prepare silk swelling solution: dilute 98% formic acid to 80% with water, then add calcium chloride to make 80% formic acid solution containing 2% calcium chloride, which is silk swelling solution;

[0038] (2) Submerge the silkworm cocoons in the swelling solution of step (1) for 30 seconds, then stretch the cocoons to twice their original length to obtain stretched cocoons;

[0039](3) The stretched cocoons obtained in step (2) are washed with deionized water, then neutralized with excess acid in 1wt% sodium hydroxide aqueous solution, washed again, and dried in an oven at 60°C to obtain high-performance natural silk fibers .

[0040] Table 2 shows the mechanical tensile data of cocoon silk before and after treatment. The cocoon silk treated according to the technical solution provided by the present invention has excellent strength, and the breaking strength reaches above 900 MPa.

[0041] Table 2 Mechanical tensile data of cocoon silk before and after treatment...

Embodiment 3

[0045] (1) Preparation of silk swelling solution: add lithium thiocyanate to 98% formic acid to make a formic acid solution containing 1% lithium thiocyanate, which is silk swelling solution;

[0046] (2) Submerge 20-22D raw silk in the swelling solution of step (1) for 50s, and then control the cocoon silk to shrink to 30% of the original length to obtain shrunk raw silk;

[0047] (3) The shrunken raw silk obtained in step (2) is washed with deionized water, then neutralized with excess acid in 1 wt% sodium hydroxide aqueous solution, washed with water again, and dried in an oven at 70°C to obtain high-performance natural silk fibers.

[0048] Table 3 shows the mechanical tensile data of the raw silk before and after treatment. The raw silk treated according to the technical scheme provided by the present invention has excellent ductility, the elongation at break reaches more than 50%, and the work of break increases by about 20%.

[0049] Table 3 Mechanical tensile data of r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com