Manufacturing method of high-residual magnetism high-coercive force rare earth permanent magnetic material

A high-coercivity, rare-earth permanent magnet technology, used in magnetic materials, magnetic objects, electrical components, etc., can solve the problems that cannot be mass-produced, permanent magnet materials are only suitable for small or thin magnets, etc. The effect of increasing tenacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

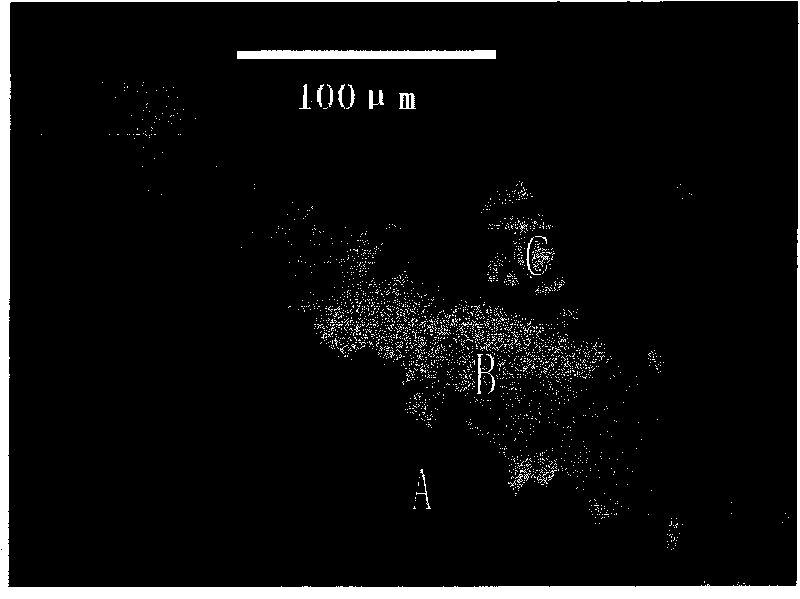

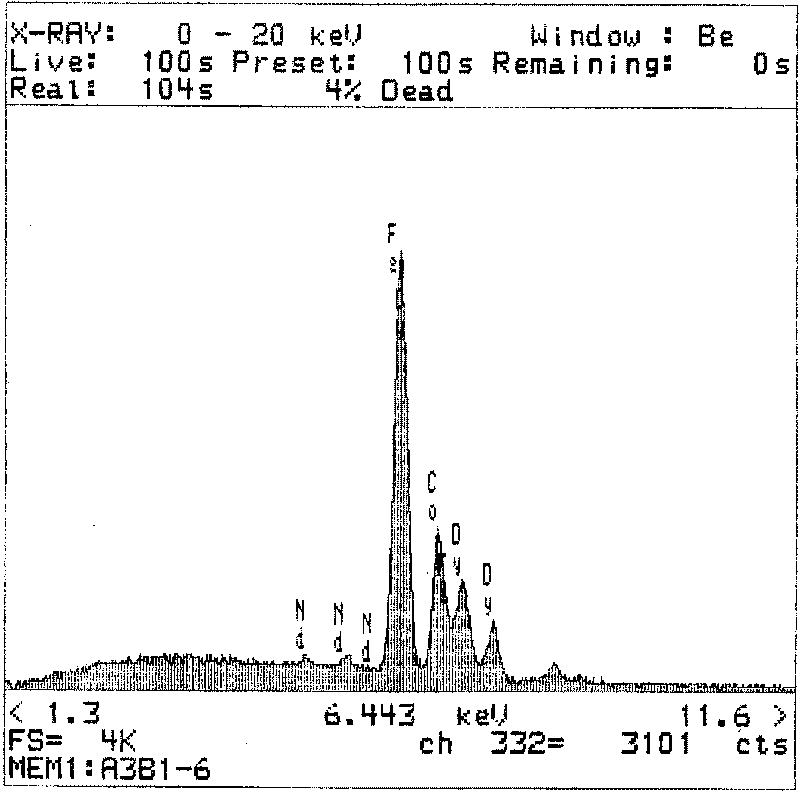

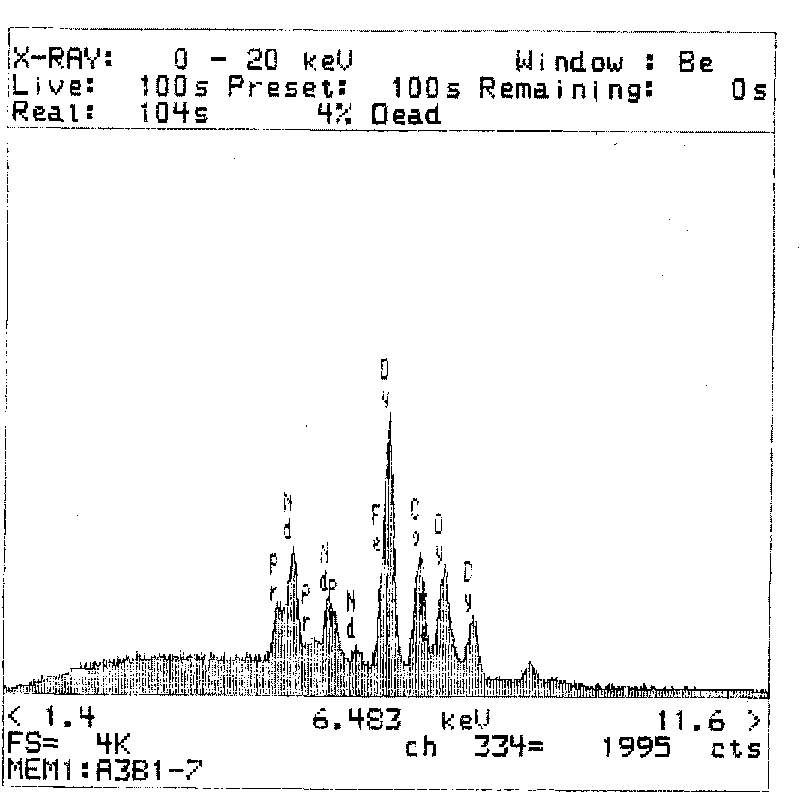

Image

Examples

Embodiment 1

[0024]Embodiment 1, preparation of master alloy: smelting metal or alloy raw materials in vacuum or inert gas atmosphere, preferably in argon atmosphere, the alloy is composed of 22% by weight of neodymium, 2% by weight of dysprosium, 7% by weight of praseodymium, 1% by weight Cobalt by weight, 1% by weight of boron, 0.3% by weight of aluminum, 0.1% by weight of copper and the balance of iron. The molten alloy is poured through the quick-setting thin strip process to obtain flake alloy flakes with a thickness between 0.2 and 0.5 mm;

[0025] Pulverization: The above-mentioned master alloy is crushed to a size of 0.1-10 mm by hydrogen, and then crushed to an average particle size of 5.0 μm on a jet mill using high-pressure nitrogen;

[0026] Molding: the fine powder produced by the above method is molded under a magnetic field, and the strength of the magnetizing magnetic field is 2 Tesla. And the density of the magnet after molding is 4.0~4.3g / cm 3 , and then carry out isost...

Embodiment 2-4

[0041] Embodiment 2-4: First, by the same process as the manufacturing process of Example 1, a plurality of sintered magnets of 10 mm × 10 mm × 10 mm are produced and then the sintered magnets are respectively buried in dysprosium copper (dysprosium 86% by weight, copper 14% by weight), Mixture of terbium copper (terbium 85% by weight, copper 15% by weight), dysprosium nickel (dysprosium 54% by weight, nickel 46% by weight) alloy with 30% by weight of dysprosium oxide, 30% by weight of dysprosium fluoride, 40% by weight of dysprosium oxyfluoride pink. The weight ratio of the alloy powder and the compound powder is 4:1, and the absorption treatment is carried out at 1000° C., and the absorption treatment time is 1 hour. After the absorption treatment, the magnet needs to be subjected to aging treatment, the temperature of the aging treatment is 520° C., and the aging time is 2 hours. Samples were made by conventional techniques.

[0042] After the sample was magnetized by a 6...

Embodiment 5-8

[0046] Embodiment 5-8, at first through the same process as the manufacturing process of embodiment 1, a plurality of sintered magnets of 5 mm × 5 mm × 5 mm are produced and then the sintered magnets are respectively embedded in dysprosium copper (dysprosium 86% by weight, copper 14% by weight) alloy Mixed powder with dysprosium oxide, dysprosium fluoride, dysprosium oxyfluoride and 50% by weight of dysprosium fluoride and 50% by weight of dysprosium oxyfluoride. The weight ratio of the alloy powder and the compound powder is 1:4, and the absorption treatment is carried out at 600° C., and the absorption treatment time is 20 hours. After the absorption treatment, the magnet needs to be subjected to aging treatment, the temperature of the aging treatment is 520° C., and the aging time is 2 hours. Samples were made by conventional techniques.

[0047] After the sample was magnetized by a 6 Tesla magnetic field, the results of comparative measurement of magnetic properties are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com