Method of manufacturing flexible stress sensor based on nano conductive material

A stress sensor and nano-conducting technology, applied in the field of biosensors, to achieve the effects of good stretchability, high sensitivity, improved sensitivity and stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

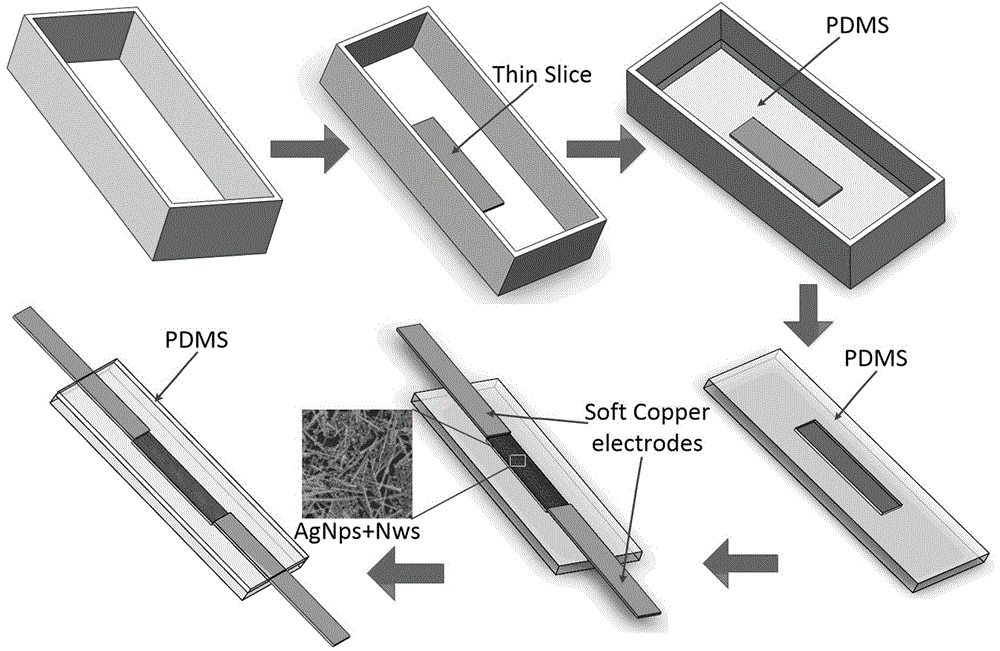

[0018] A method for preparing a flexible stress sensor based on conductive nanomaterials, comprising the steps of:

[0019] 1) Take a flat-bottomed container and place a sheet in the center of the flat-bottomed container;

[0020] 2) Prepare the PDMS solution, take the main agent and the curing agent at a mass ratio of 10:1, put it in a petri dish and mix evenly, and use a vacuum drying oven to evacuate for 10 minutes to break the bubbles in the mixed solution to obtain a PDMS solution without bubbles on the surface;

[0021] 3) Add the PDMS solution prepared in step 2) into the flat-bottomed container prepared in step 1), so that the PDMS solution covers the sheet;

[0022] 4) Put the flat-bottomed container containing PDMS and flakes into 70 o Heating in the drying oven of C for 1.5h, the PDMS solution forms a PDMS film;

[0023] 5) Take out the PDMS film in the flat-bottomed container, remove the sheet, and obtain a PDMS flexible template with grooves;

[0024] 6) After ...

Embodiment 1

[0031] 1) Take a 2*1cm rectangular low-wall flat-bottomed container, and put a 0.8*0.3*0.05cm silicon wafer in the center;

[0032] 2) Prepare the PDMS solution, take the main agent and the curing agent at a mass ratio of 10:1, put it in a petri dish and mix evenly, and use a vacuum drying oven to evacuate for 10 minutes to break the bubbles in the mixed solution to obtain a PDMS solution without bubbles on the surface;

[0033] 3) Take the PDMS solution prepared in step 2) and add it to the container prepared in step 1);

[0034] 4) Put the container with PDMS and silicon wafer into 70 o Heating in a drying oven at C for 1.5h;

[0035] 5) Take out the PDMS film in the container, remove the silicon wafer, and obtain a PDMS flexible template with grooves;

[0036] 6) After drawing out the electrodes with conductive copper tape on the two narrow sides of the groove, fill the groove with silver nanowires, a nano-conductive material;

[0037] 7) After the sol is completely dry,...

Embodiment 2

[0039] A core-shell structure conductive polyaniline / Co 3 o 4 The preparation method of powder, comprises the steps:

[0040] 1) Take a circular container with a short wall and a flat bottom with a diameter of 2 cm, and place a silicon wafer with a diameter of 0.8 cm and a thickness of 0.05 cm in the center;

[0041] 2) Prepare the PDMS solution, take the main agent and the curing agent at a mass ratio of 10:1, put it in a petri dish and mix evenly, and use a vacuum drying oven to evacuate for 10 minutes to break the bubbles in the mixed solution to obtain a PDMS solution without bubbles on the surface;

[0042] 3) Take the PDMS solution prepared in step 2) and add it to the container prepared in step 1);

[0043] 4) Put the container with PDMS and silicon wafer into 70 o Heating in a drying oven at C for 1.5h;

[0044] 5) Take out the PDMS film in the container, remove the silicon wafer, and obtain a PDMS flexible template with grooves;

[0045] 6) After the electrodes are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com