Method for preparing Al-base composite material

An aluminum-based composite material and aluminum-based alloy technology, which is applied in the field of metal-based composite material preparation, can solve problems such as affecting the performance of composite materials, and achieve the effects of reducing porosity, improving mechanical properties, and improving wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

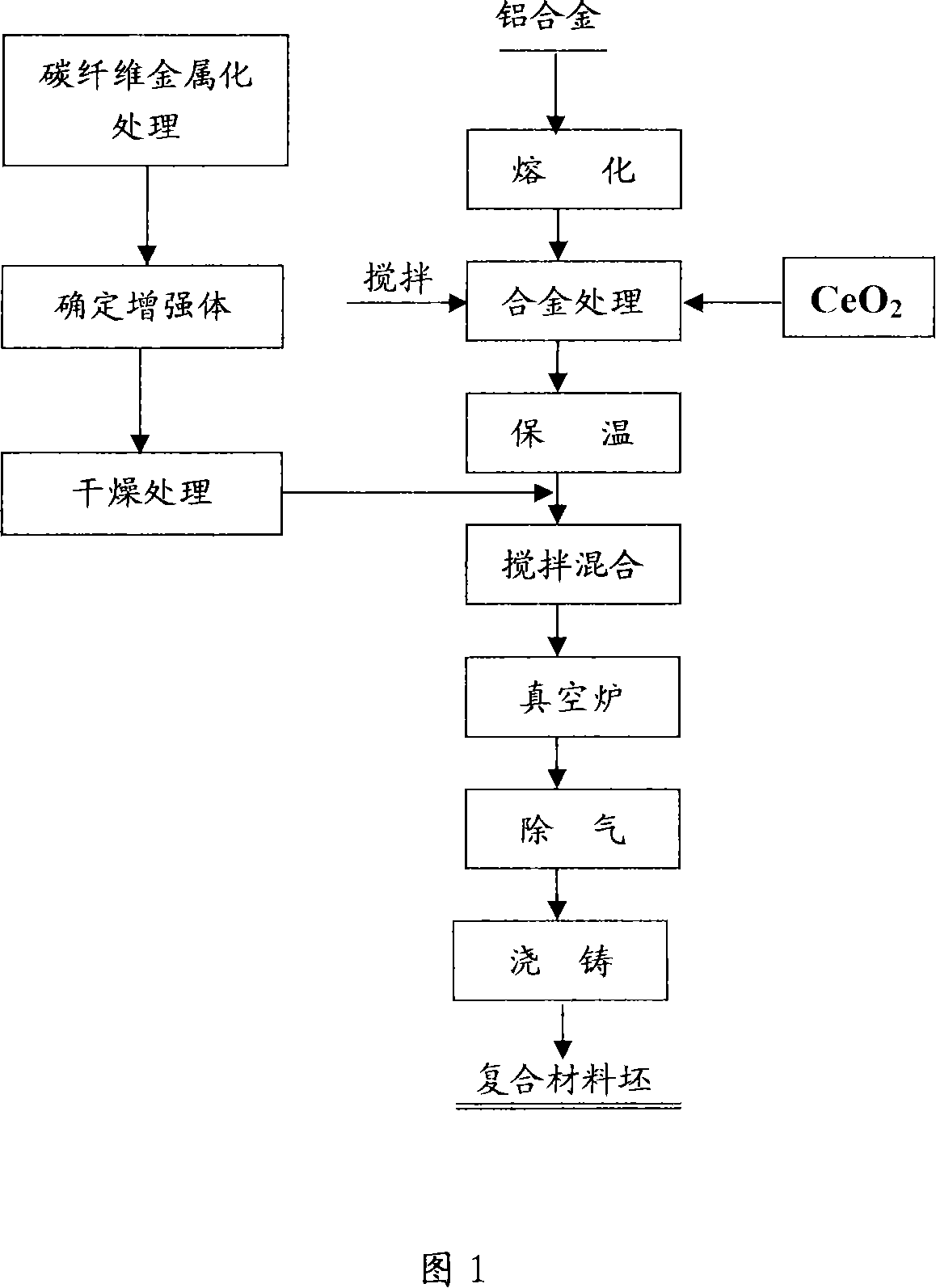

Image

Examples

Embodiment Construction

[0031] 1. Example of composite material preparation process

[0032] 1-1 example:

[0033] Select 800g of aluminum alloy as the base, and add 0.15wt% analytically pure CeO at 750°C after the aluminum alloy is completely melted 2 powder while stirring with a mechanical stirring paddle to make analytically pure CeO2 Evenly dispersed in aluminum alloy. Then take carbon fibers with 3% of the total amount of the matrix alloy, electroless nickel-plate the surface for 15 minutes, and make short carbon fibers, the length of which is 2 mm, and add them to the alloy melt treated with the matrix alloy and stir at a stirring temperature of 720 ° C. 5min, the stirring speed is 900r / min, and then the composite material melt is sent into the vacuum furnace for vacuum degassing treatment. The vacuum furnace temperature is 720°C, the vacuum degree is 0.01MPa, and the vacuum degassing time is 1.5min, namely Short carbon fiber reinforced aluminum alloy composites are available.

[0034] 1-2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com