High-entropy alloy particle-reinforced aluminum-based composite material and preparation method thereof

A particle-reinforced aluminum and high-entropy alloy technology, which is applied in the field of composite material preparation, can solve problems such as its own brittleness and sintering temperature limitation, affecting material densification, and difficulty in realizing the strength and plasticity of composite materials, achieving low energy consumption and cost, Easy to achieve, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

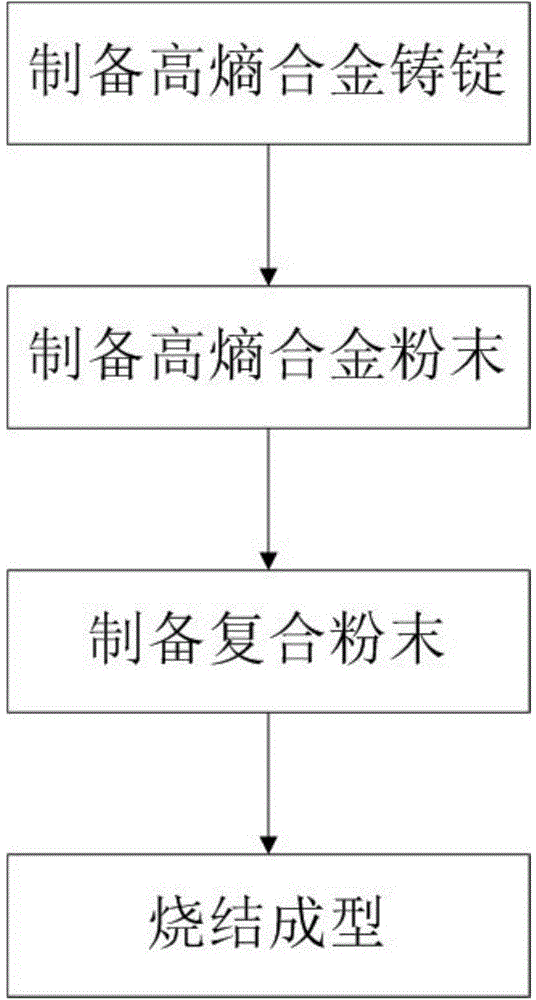

[0034] Embodiment 1: including the step of preparing high-entropy alloy ingot, the step of preparing high-entropy alloy powder, the step of preparing composite powder and the step of sintering molding:

[0035] (1) Steps for preparing high-entropy alloy ingots:

[0036] Weigh aluminum, cobalt, chromium, iron, nickel, and titanium sponge according to the atomic ratio Al: Co: Cr: Fe: Ni: Ti = 1: 1: 1: 1: 1: 0.5, and place them in a vacuum In the water-cooled copper crucible in the consumable electrode electric arc furnace, the melting is carried out in a vacuum environment, and the protection of Ar gas is introduced, and the melting is repeated 3 times to prevent composition segregation, and a high-entropy alloy ingot with uniform composition is obtained;

[0037] The purity of each raw material is not less than 99.5wt.%. When placed in a water-cooled copper crucible, each raw material is placed from bottom to top according to its melting point from low to high;

[0038] (2) St...

Embodiment 2

[0050] The difference with Example 1 is: repeated smelting 5 times in the step (1); ball milling process parameters in the step (2): the ball-to-material ratio is 15: 1, the rotating speed is adjusted to 200r / min, and the ball milling time is adjusted to 1h; the step ( 3) The volume ratio of high-entropy alloy powder particles and aluminum powder is 1:4, and the ball milling process parameters are as follows: the mass ratio of ball to material is 10:1, the speed is adjusted to 100r / min, and the ball milling time is adjusted to 3h; in step (4), discharge The plasma process parameters are adjusted as follows: sintering temperature is 550°C, holding time is 6min, pressure is 50MPa during sintering, heating rate is 100°C / min, vacuum degree -3 pa.

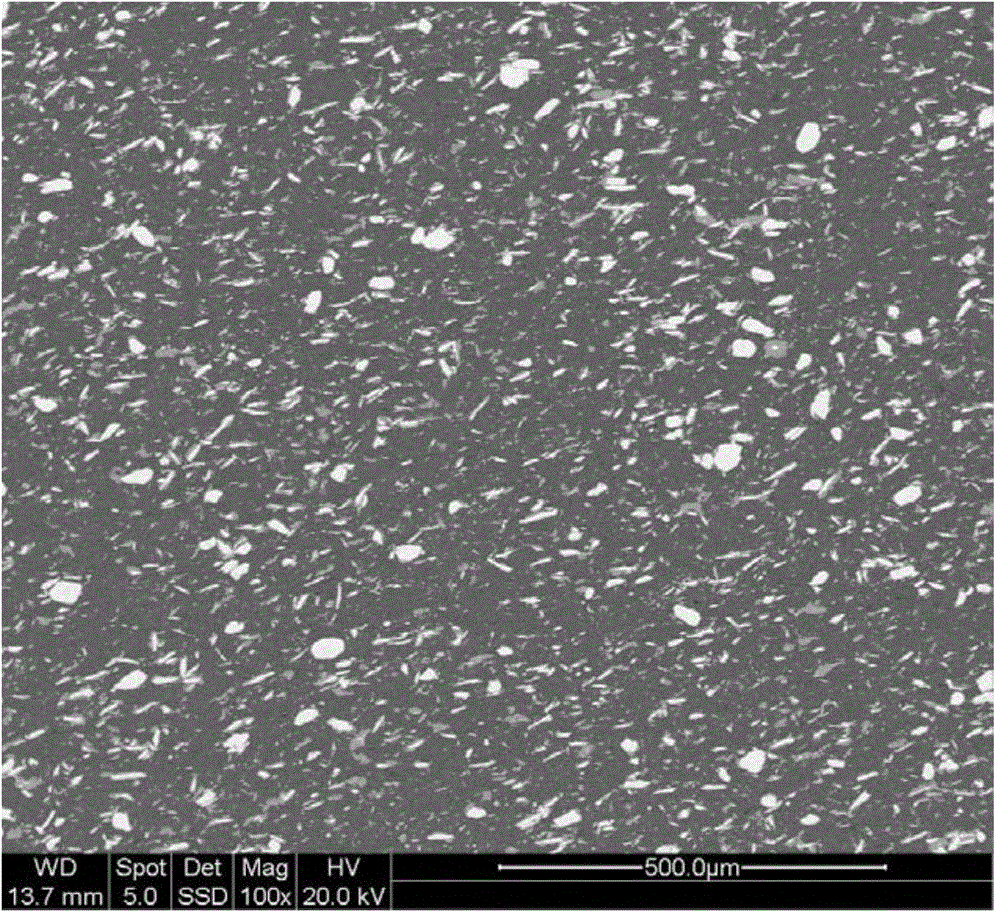

[0051] The AlCoCrFeNiTi that embodiment 2 makes 0.5 The backscattering (SSD) spectrum of high-entropy alloy reinforced aluminum matrix composites is as follows: image 3 shown. The bright area in the figure is the high-entropy alloy r...

Embodiment 3

[0053] The difference with Example 1 is that: step (4) adopts hot pressing sintering process to carry out sintering, the sintering temperature is 550 DEG C, the holding time is 1h, the pressure 400MPa is applied during sintering, and the vacuum degree-3 Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com