Full water-soluble nitro compound fertilizer and preparation method thereof

A nitro compound fertilizer, water-soluble technology, applied in the direction of fertilization device, fertilizer mixture, application, etc., to prevent the particles from sticking to the block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

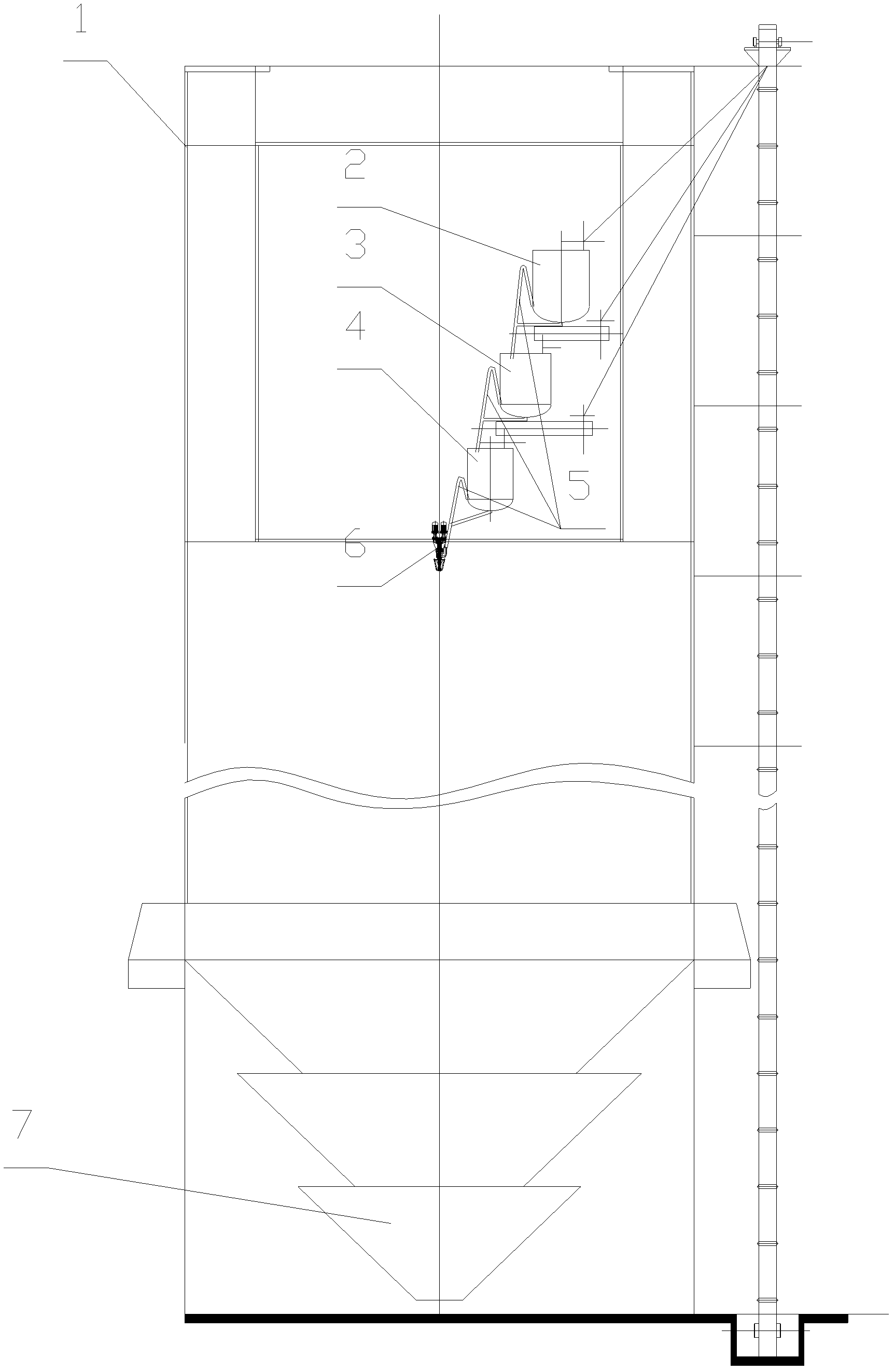

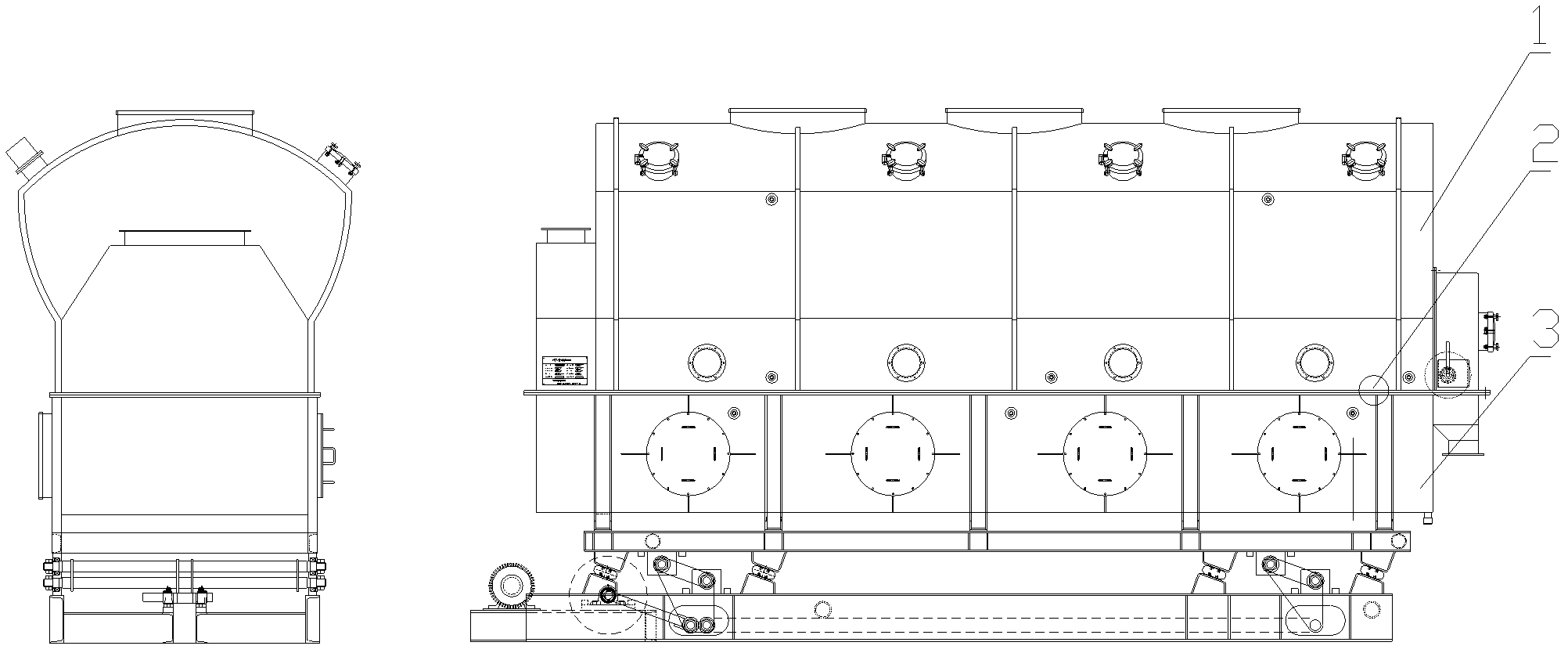

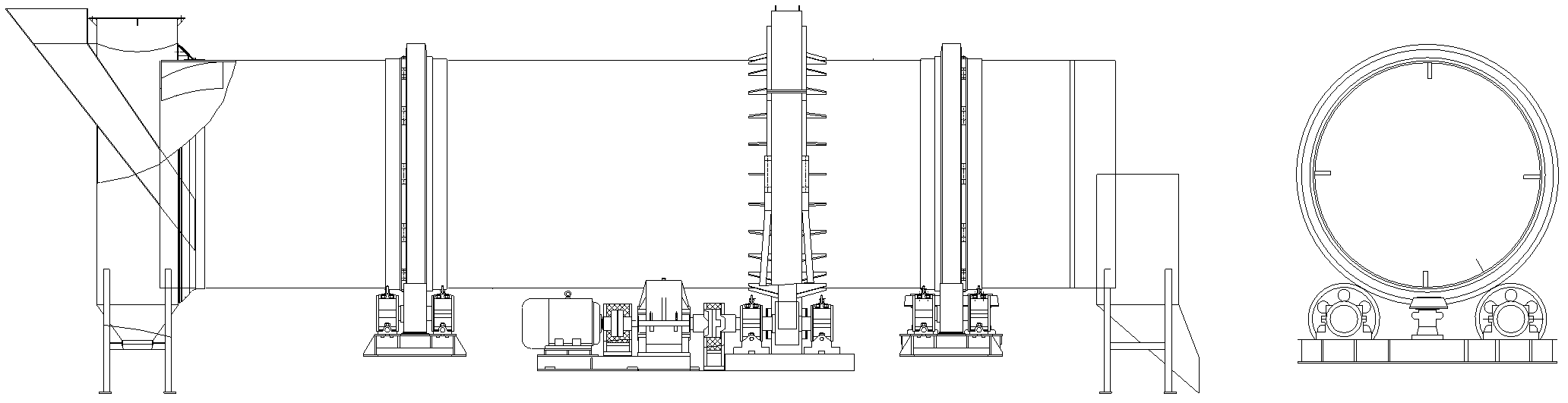

Method used

Image

Examples

Embodiment 1

[0034] The fully water-soluble nitro compound fertilizer of the present embodiment mainly comprises following parts by weight material: modified ammonium nitrate: industrial monoammonium phosphate: potassium chloride: borax=1: 0.8: 0.5: 0.2, wherein said modified ammonium nitrate is Contains P 2 o 5 6 wt% modified ammonium nitrate.

[0035] (1) In the melting pot, add P 2 o 5 1 part of 6wt% modified ammonium nitrate and 0.128 part of industrial monoammonium phosphate (mixture P 2 o 5 content of 12wt%), the temperature is controlled at 165°C, under constant stirring, it is indirectly heated and melted with steam, and when the pot is full, it overflows into the primary mixing pot through the feed pipe;

[0036] (2) In the primary mixing pot, add 0.672 parts of industrial monoammonium phosphate to the melted material, keep stirring and heating, control the temperature at 150°C, and the mixed melt will naturally overflow to the secondary mixing pot ;

[0037] (3) Add 0.5 pa...

Embodiment 2

[0042] The fully water-soluble nitro compound fertilizer of the present embodiment mainly comprises following parts by weight material: modified ammonium nitrate: industrial monoammonium phosphate: potassium sulfate: EDTA complex or boron fertilizer=1: 0.3: 0.9: 0, wherein said Modified ammonium nitrate containing P 2 o 5 10 wt% modified ammonium nitrate.

[0043] (1) In the melting pot, add P 2 o 5 1 part of 10wt% modified ammonium nitrate, control the temperature at 172°C, heat and melt indirectly with steam under constant stirring, and overflow into the first-stage mixing pot through the material pipe after the pot is full;

[0044] (2) In the primary mixing pot, add 0.3 parts of industrial monoammonium phosphate to the molten modified ammonium nitrate, keep stirring and heating, control the temperature at 160°C, and the mixed melt will naturally overflow to the secondary mixing pot;

[0045] (3) Add 0.9 parts of potassium sulfate in the secondary mixing pot, heat and ...

Embodiment 3

[0050] The fully water-soluble nitro compound fertilizer of the present embodiment mainly includes the following materials in parts by weight: modified ammonium nitrate: industrial monoammonium phosphate: potassium sulfate: EDTA-Cu=1: 0.55: 0.7: 0.055, wherein the modified ammonium nitrate for containing P 2 o 5 10 wt% modified ammonium nitrate.

[0051] (1) In the melting pot, add P 2 o 5 1 part of 10wt% modified ammonium nitrate, control the temperature at 168°C, heat and melt indirectly with steam under constant stirring, and overflow into the first-stage mixing pot through the material pipe after the pot is full;

[0052] (2) In the primary mixing pot, add 0.55 parts of industrial monoammonium phosphate to the molten modified ammonium nitrate, keep stirring and heating, control the temperature at 155°C, and the mixed melt will naturally overflow to the secondary mixing pot;

[0053] (3) Add 0.7 parts of potassium sulfate and 0.055 parts of EDTA-Cu into the secondary m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com