Ceramic/polymer composite with high dielectric constant and preparation method thereof

A high dielectric constant, polymer material technology, applied in the field of composite materials, can solve the problems of unfavorable ceramic powder dispersion, increased dielectric loss of materials, uneven microstructure, etc., to reduce dielectric loss and increase dielectric constant. , the effect of good combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing a high dielectric constant ceramic-polymer composite material, comprising:

[0035] Step 1, dissolving the silane coupling agent in the first solvent to prepare a first solution;

[0036] Step 2, after mixing the ceramic powder with the first solution, preparing a suspension;

[0037] Step 3, dissolving the polymer material in the second solvent to prepare a second solution;

[0038] Step 4. After mixing the suspension with the second solution, a ceramic-polymer composite slurry is prepared;

[0039] Step 5, after preparing the ceramic-polymer composite material slurry into a solid film, modifying the solid film by heat treatment;

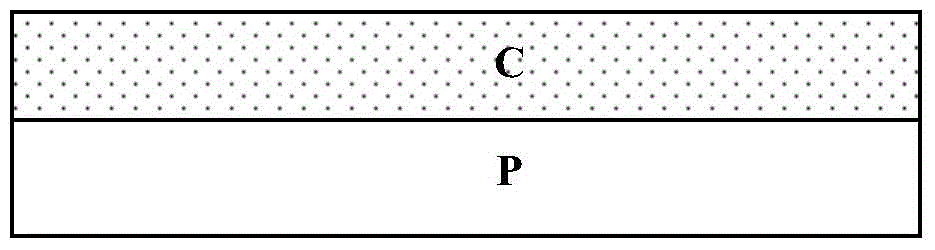

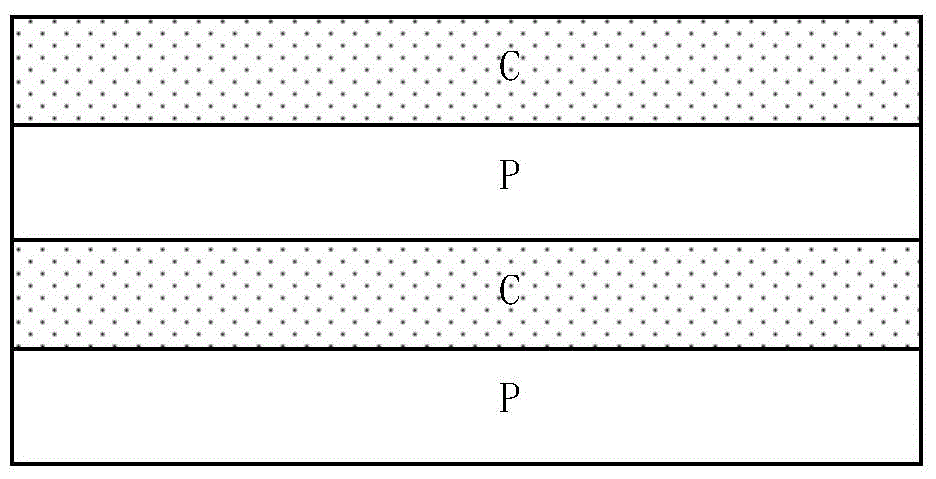

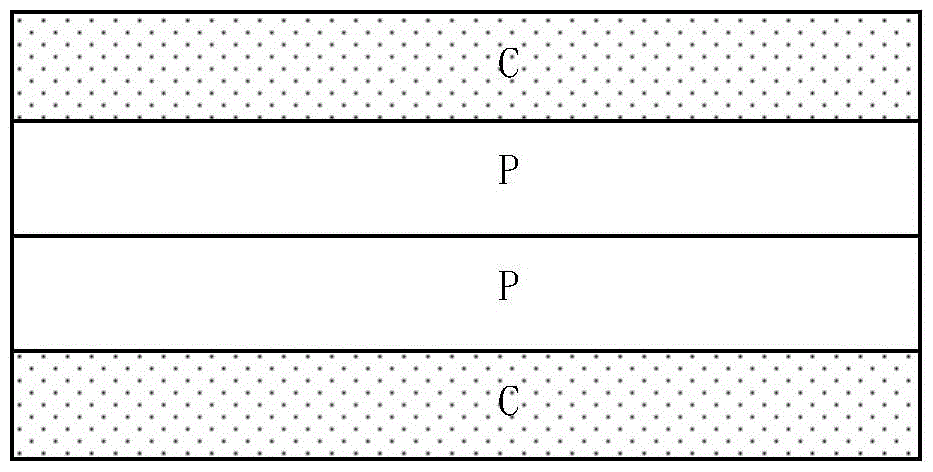

[0040] Step 6: After pressing together the surfaces with higher polymer density in the two solid films, a multi-layer composite material is produced.

[0041] In step 3, after the silane coupling agent is dissolved in the first solvent to prepare the first solution, after mixing with the ceram...

Embodiment 1

[0056] A method for preparing a high dielectric constant ceramic-polymer composite material, comprising:

[0057] Step 1. Dissolving the silane coupling agent in ethanol to prepare the first solution, specifically: adding the silane coupling agent to the first solvent to hydrolyze to obtain a hydrolyzed solution, then fully stirring the hydrolyzed solution to prepare the first solution solution.

[0058] In this embodiment, the first solvent is an ethanol solvent composed of 95% ethanol and 5% water, and the silane coupling agent is added to the ethanol solvent, and wait for 5 minutes to hydrolyze it to form silanol, and then stir for 12 hours. Prepare the first solution.

[0059] Step 2, barium strontium titanate (BaSrTiO 3 , BST) ceramic powder was mixed with the first solution to prepare barium strontium titanate-silane coupling agent suspension.

[0060] Step 3, dissolving the polymer material polyvinylidene fluoride-chlorotrifluoroethylene P (VDF-CTFE) in a second solv...

Embodiment 2

[0067] A method for preparing a high dielectric constant ceramic-polymer composite material, comprising:

[0068] Step 1. Dissolving the silane coupling agent in ethanol to prepare the first solution, specifically: adding the silane coupling agent to the first solvent to hydrolyze to obtain a hydrolyzed solution, then fully stirring the hydrolyzed solution to prepare the first solution solution.

[0069] Step 2, barium strontium titanate (BaSrTiO 3 , BST) ceramic powder was mixed with the first solution to prepare barium strontium titanate-silane coupling agent suspension.

[0070] Step 3, dissolving the polymer material polyvinylidene fluoride-chlorotrifluoroethylene P (VDF-CTFE) in a second solvent to prepare a second solution, wherein the mixing ratio of VDF / CTFE is 88 / 12 mol%;

[0071] The volume ratio of BST to polymer matrix was 40%.

[0072] Step 4. After mixing the barium strontium titanate-silane coupling agent suspension with the second solution, ultrasonically di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com