Preparation method of silicone rubber surface hydrophilic coating

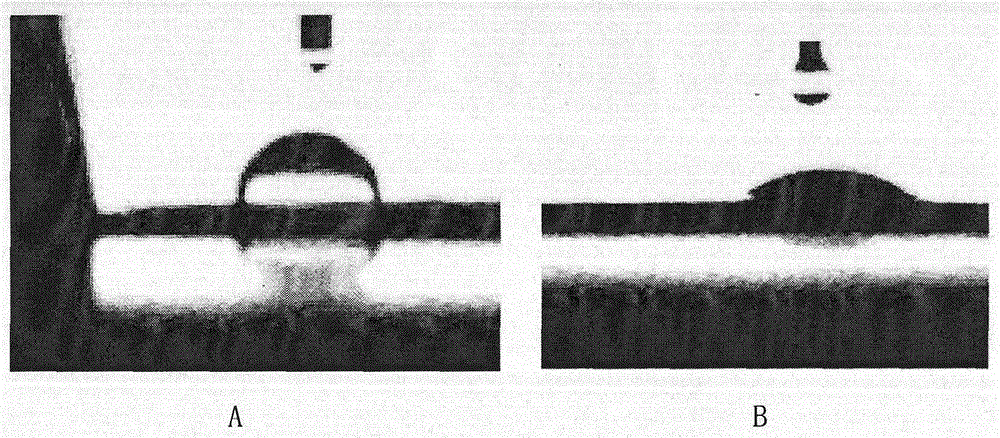

A hydrophilic coating and silicone rubber technology, applied in the field of biomedical materials, can solve the problems of expensive oxygen plasma equipment and harsh operating conditions, and achieve the effects of simple process and equipment, easy promotion, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step (1): 3-aminopropyltriethoxysilane (APTS) solution with a concentration of 1.5wt% is configured in an ethanol / water mixed solvent; the silicone rubber material is immersed in the above-mentioned APTS solution, stirred, and reacted for 1.5 hours, Take it out, rinse it with ethanol, and dry it to obtain a surface-aminated silicone rubber;

[0031] Step (2): polyethyleneimine and NaOH with a molecular weight of 1500 g / mol are dissolved in deionized water to obtain a solution, the concentration of polyethyleneimine in the solution is 30wt%, the concentration of NaOH is 1wt% of water, and the temperature of the solution is constant At 50°C; add epichlorohydrin to the above solution, so that the molar ratio of polyethyleneimine to epichlorohydrin is 5:1, stir immediately to make the solution evenly mixed; quickly mix the aminated silicone rubber obtained in step (1) Immerse in the above polyethyleneimine aqueous solution, react at 50°C for 4.5 hours, take it out, dry it n...

Embodiment 2

[0036] Step (1): Prepare a 2.5wt% 3-aminopropyltriethoxysilane (APTS) solution in an ethanol / water mixed solvent; immerse the silicone rubber material in the APTS solution, stir, and react for 1.5 hours. Take it out, rinse it with ethanol, and dry it to obtain a surface-aminated silicone rubber;

[0037] Step (2): polyethyleneimine and NaOH with a molecular weight of 3500 g / mol are dissolved in deionized water to obtain a solution, the concentration of polyethyleneimine in the solution is 17wt%, the concentration of NaOH is 1wt% of water, and the temperature of the solution is constant At 50°C; add epichlorohydrin to the above solution, so that the molar ratio of polyethyleneimine to epichlorohydrin is 9:1, stir immediately to make the solution evenly mixed; quickly mix the aminated silicone rubber obtained in step (1) Immerse in the above polyethyleneimine aqueous solution, react at 50°C for 4.5 hours, take it out, dry it naturally for 10 minutes, soak it with 2wt% sulfuric a...

Embodiment 3

[0040] Step (1): Prepare a 2wt% 3-aminopropyltriethoxysilane (APTS) solution in an ethanol / water mixed solvent; immerse the silicone rubber material in the APTS solution, stir, react for 1.5 hours, and take out , rinsed with ethanol, dried to obtain surface aminated silicone rubber;

[0041] Step (2): polyethyleneimine and NaOH with a molecular weight of 5200 g / mol are dissolved in deionized water to obtain a solution, the concentration of polyethyleneimine in the solution is 5wt%, the NaOH addition is 1wt% of water, and the solution temperature Constant at 50°C; add epichlorohydrin to the above solution, so that the molar ratio of polyethyleneimine to epichlorohydrin is 4.5:1, stir immediately to make the solution evenly mixed; quickly mix the silicon amide obtained in step (1) Immerse the rubber in the above polyethyleneimine aqueous solution, react at 50°C for 4.5 hours, take it out, dry it naturally for 10 minutes, soak it with 2wt% sulfuric acid aqueous solution at room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com