Electrified thermal stretching testing device and stretching testing method

A test device and tensile test technology are applied in the direction of applying stable tension/pressure to test the strength of materials, etc., which can solve the problems of uneven heating of the tensile test piece, so as to avoid coating aging and peeling off, long service life, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

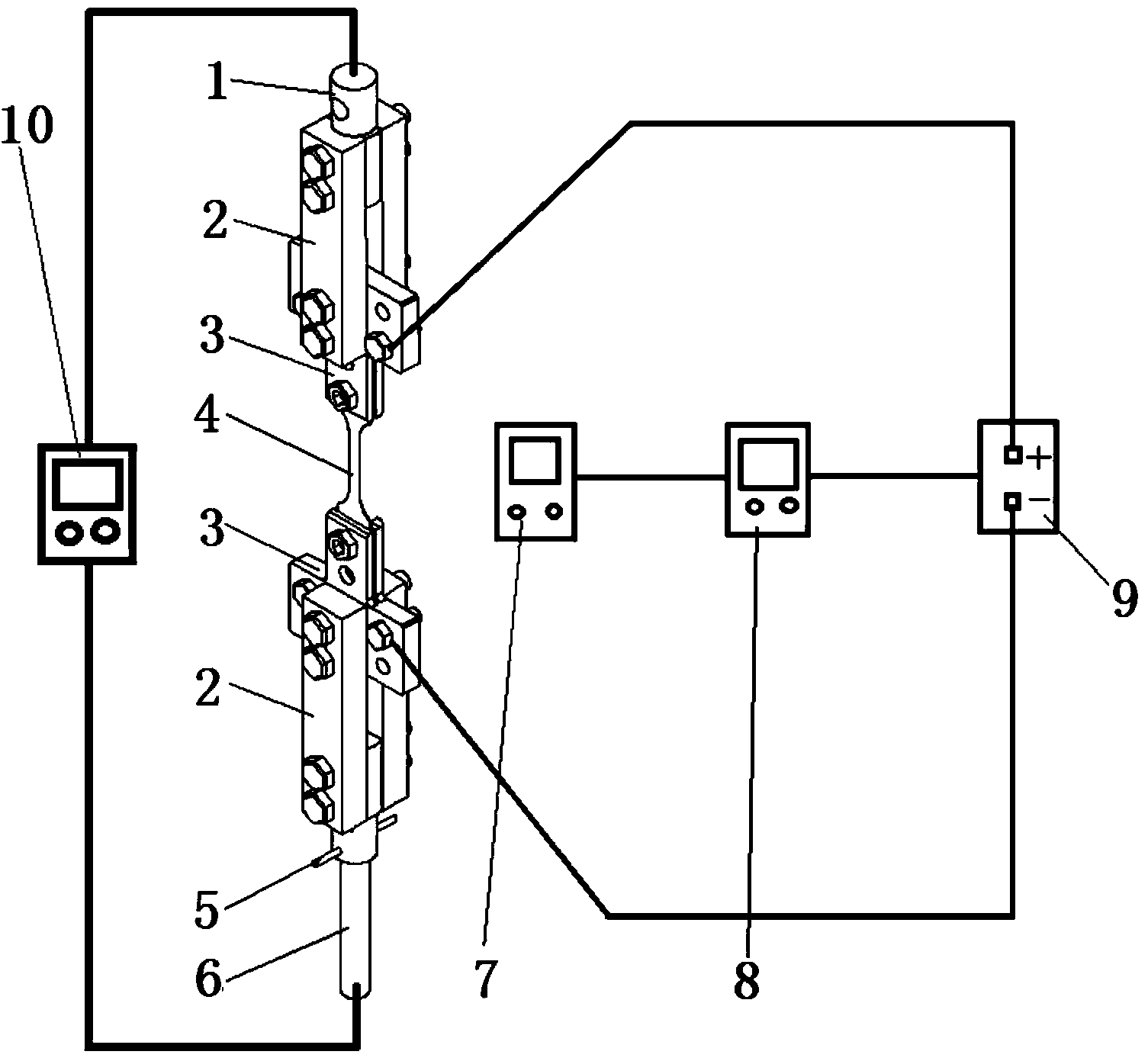

[0038] In this embodiment, an electrified thermal tensile test device includes a uniaxial tensile test device and a temperature control device. The uniaxial tensile test device includes an electronic universal testing machine 10 and a set of fixtures insulated from the machine tool bed; the temperature control device includes a temperature measurement unit 7, a power regulator 8 and a power supply device 9. The temperature measurement unit 7 includes an infrared temperature sensor, a temperature comparator, a temperature threshold setting panel and a temperature display.

[0039] The electronic universal testing machine 10 is in the prior art.

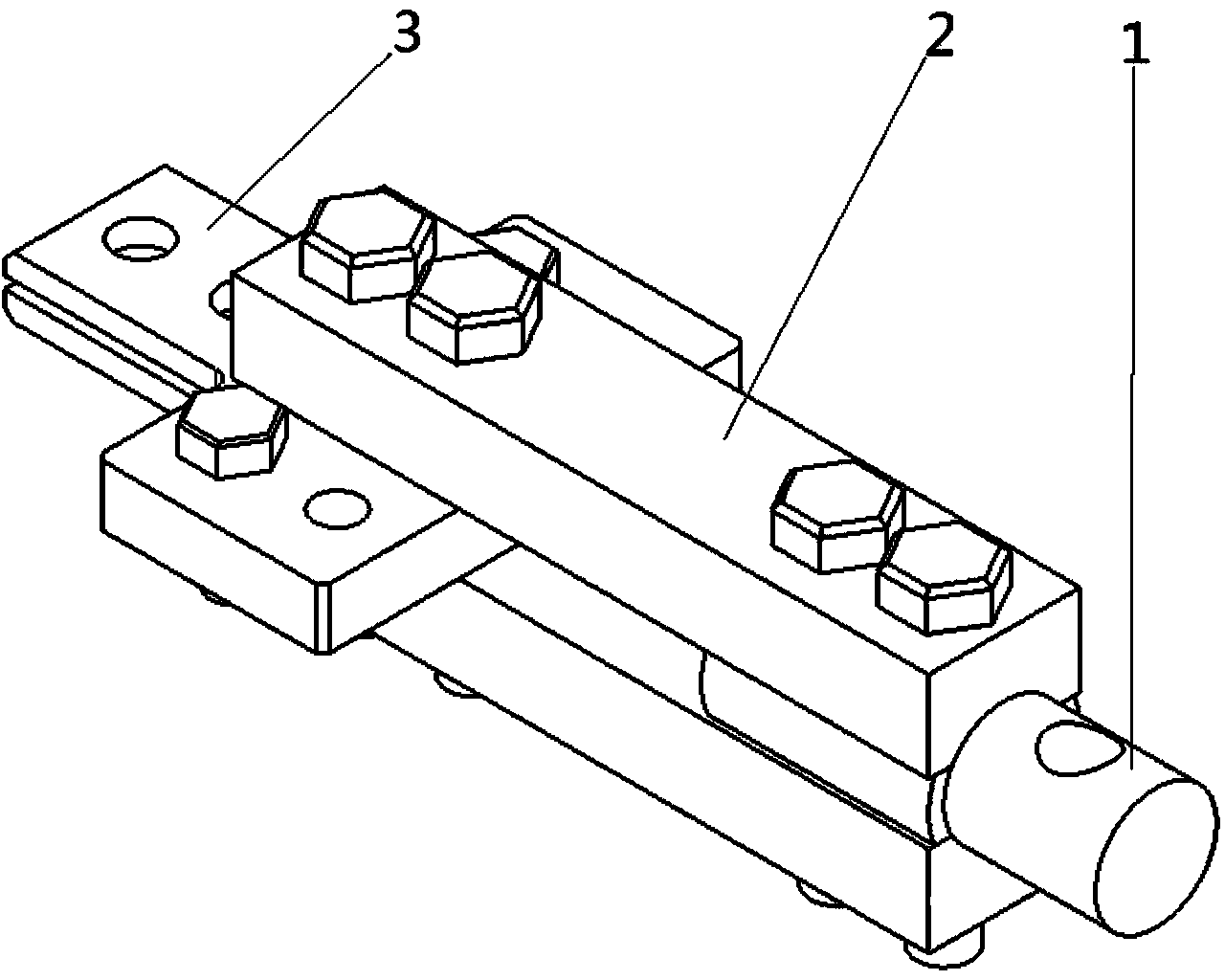

[0040] The jig includes an upper jig and a lower jig, and the upper jig and the lower jig are used in a set. The upper jig and the lower jig have the same structural features and are designed based on the CSS-44100 electronic universal testing machine. In this embodiment, the upper jig is described as an example.

[0041] The upper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com