Vibration stress relief formation method and device under elastic deformation condition

A vibration aging and elastic deformation technology is applied in the field of vibration aging forming methods and devices, which can solve the problems of difficult springback and high mold manufacturing cost, and achieve the effects of reducing production costs, good surface quality and less equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment is a method of vibration aging forming under elastic deformation conditions, and the specific steps are:

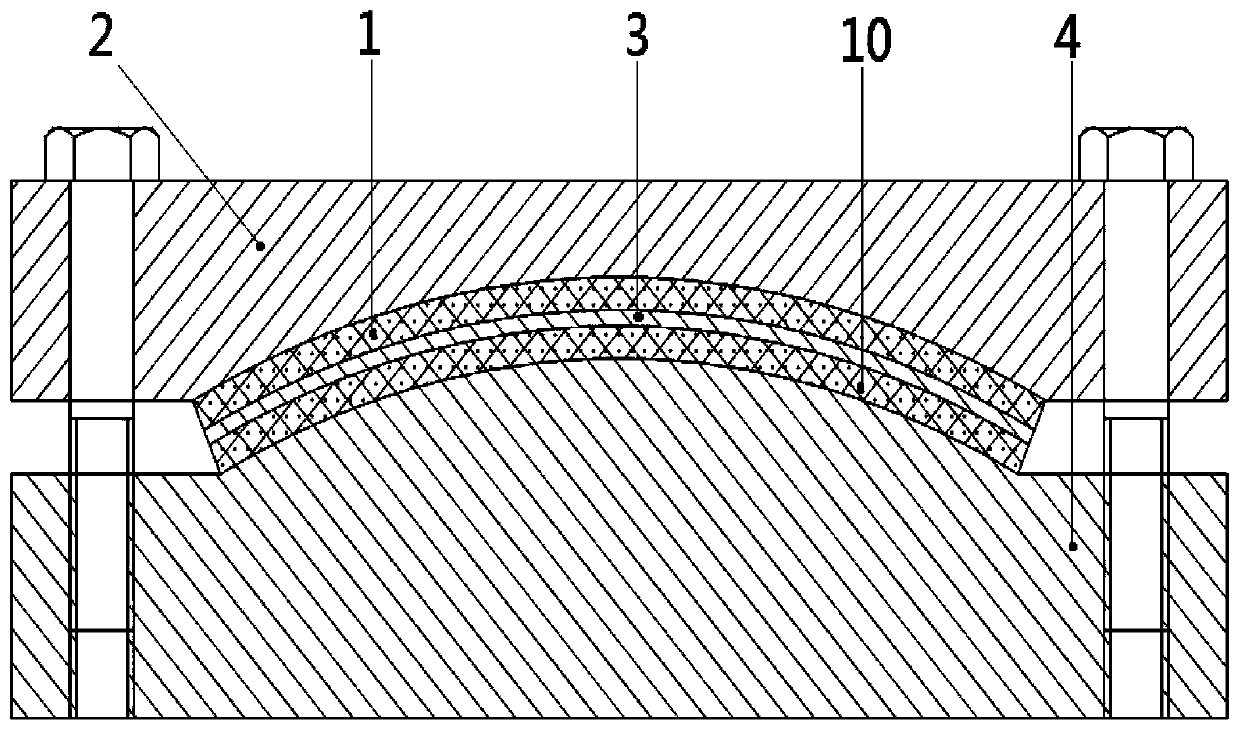

[0029] In the first step, the sheet metal of the workpiece to be formed is installed. Install the sheet material and the rubber pad of the workpiece to be formed between the upper mold and the lower mold, and make the upper surface of the first rubber pad fit the lower surface of the upper mold, and the lower surface of the second rubber pad and the lower mold. The upper surface is attached, and at the same time, the upper surface of the sheet material of the workpiece to be formed is attached to the lower surface of the first rubber pad, and the lower surface of the sheet material of the workpiece to be formed is attached to the upper surface of the second rubber pad. Secure the exciter to the sheet with conventional "C" clips. Connect the exciter and sensor and the power supply through the cable and power cord. Among them, the exciter chooses ZS...

Embodiment 2

[0034] This embodiment is a single-curvature workpiece forming device used to implement the vibration aging forming method under elastic deformation conditions described in Embodiment 1. The length of the formed workpiece is 1000mm, the width is 400mm, and the bending radius is 1500mm. The formed workpiece is an aluminum alloy plate.

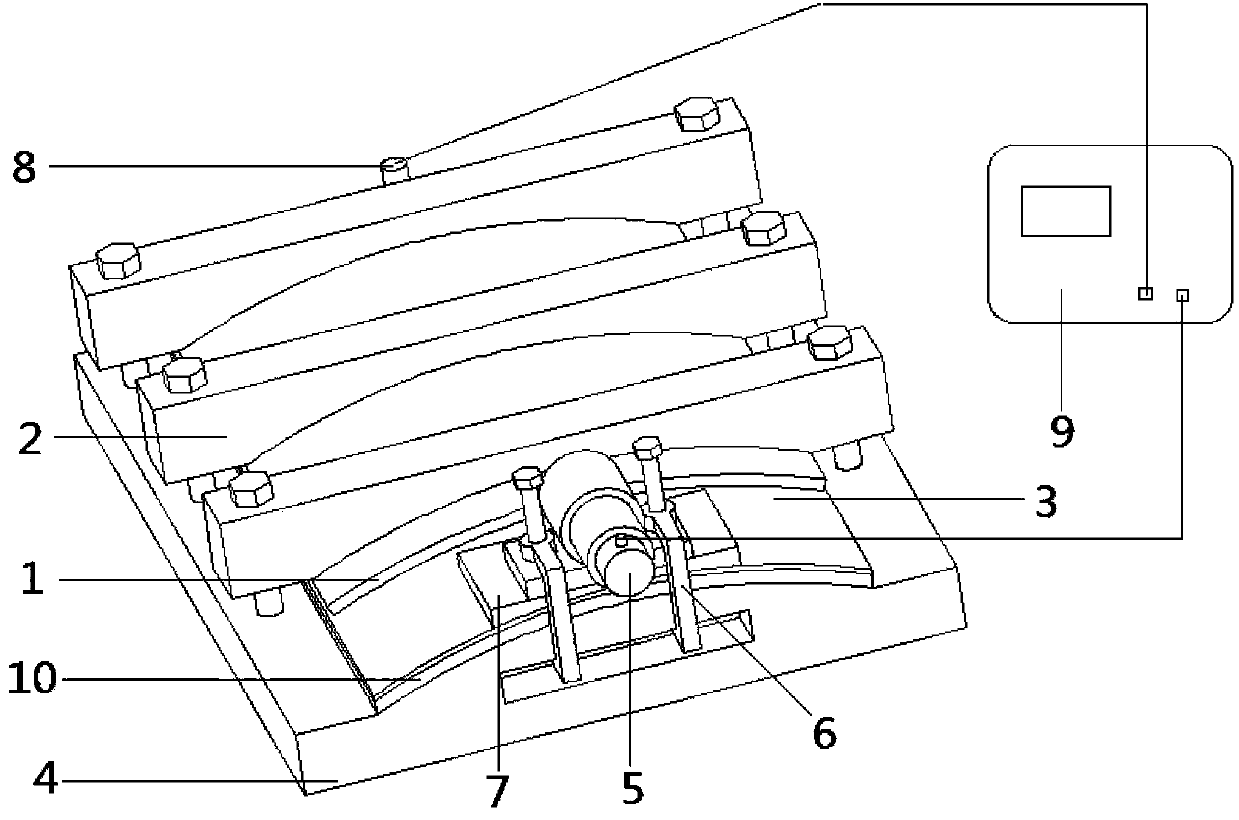

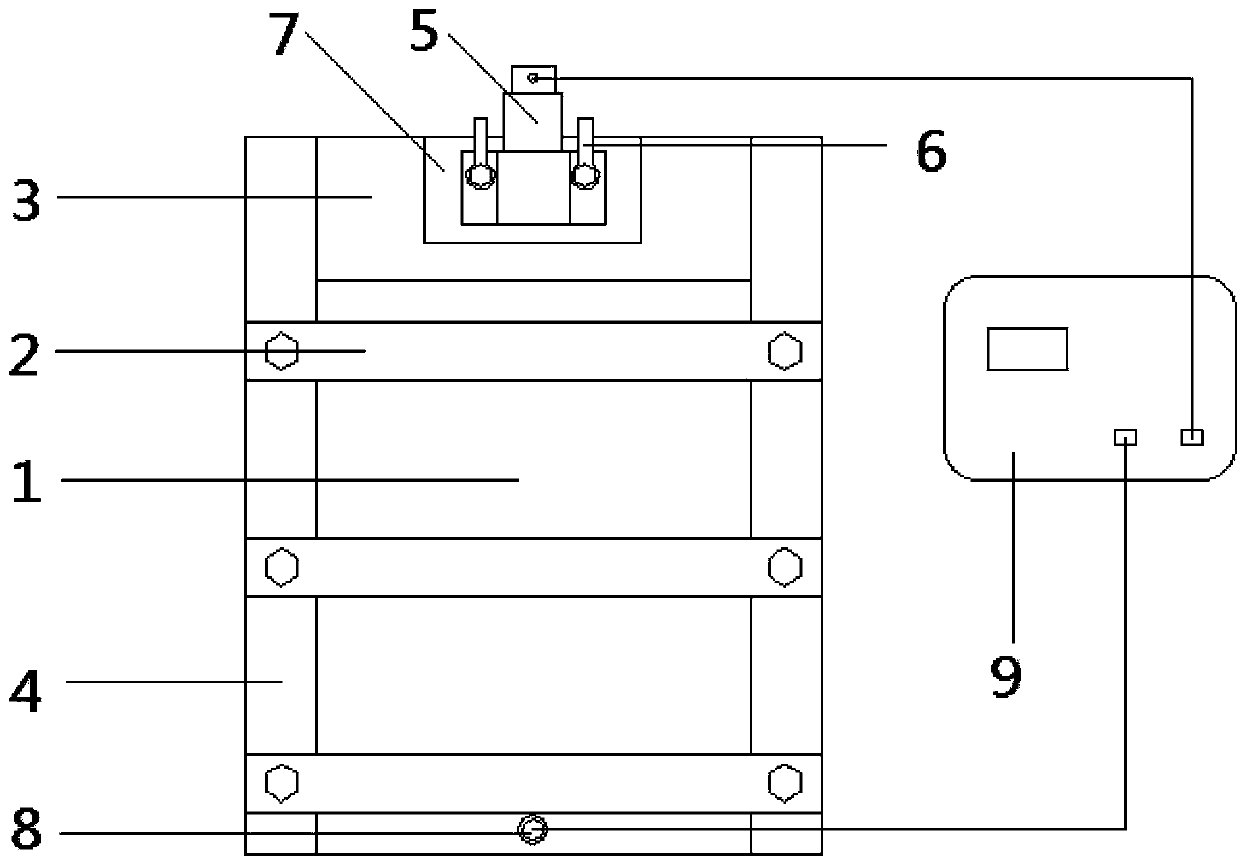

[0035] The forming device of the single-curvature aluminum alloy workpiece comprises the first rubber pad 1 of the forming device, an upper mold 2, a lower mold 4, an exciter 5, a clamp 6, an exciter base 7, a sensor 8, a controller 9 and The second rubber pad 10.

[0036] The vibrator 5 is located at one end of the workpiece, and is installed on the upper surface of the workpiece 3 through the vibrator base 7 . The upper surface of the exciter base 7 cooperates with the bottom plate of the exciter, and the vibrator 5, the exciter base 7 and the lower mold 4 are fastened by the clamp 6. The lower surface of the vibrator base 7 is an arc surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Bending radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com