Composite membrane bioreactor for improving particle size distribution of activated sludge and microenvironment

A technology of membrane bioreactor and particle size distribution, which is applied in the direction of aerobic and anaerobic process treatment, can solve the problems of denitrification efficiency to be improved, treatment cost increase, and reduce the service life of membrane components, so as to promote denitrification Effect of denitrification, reduction of backwash frequency, and reduction of treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

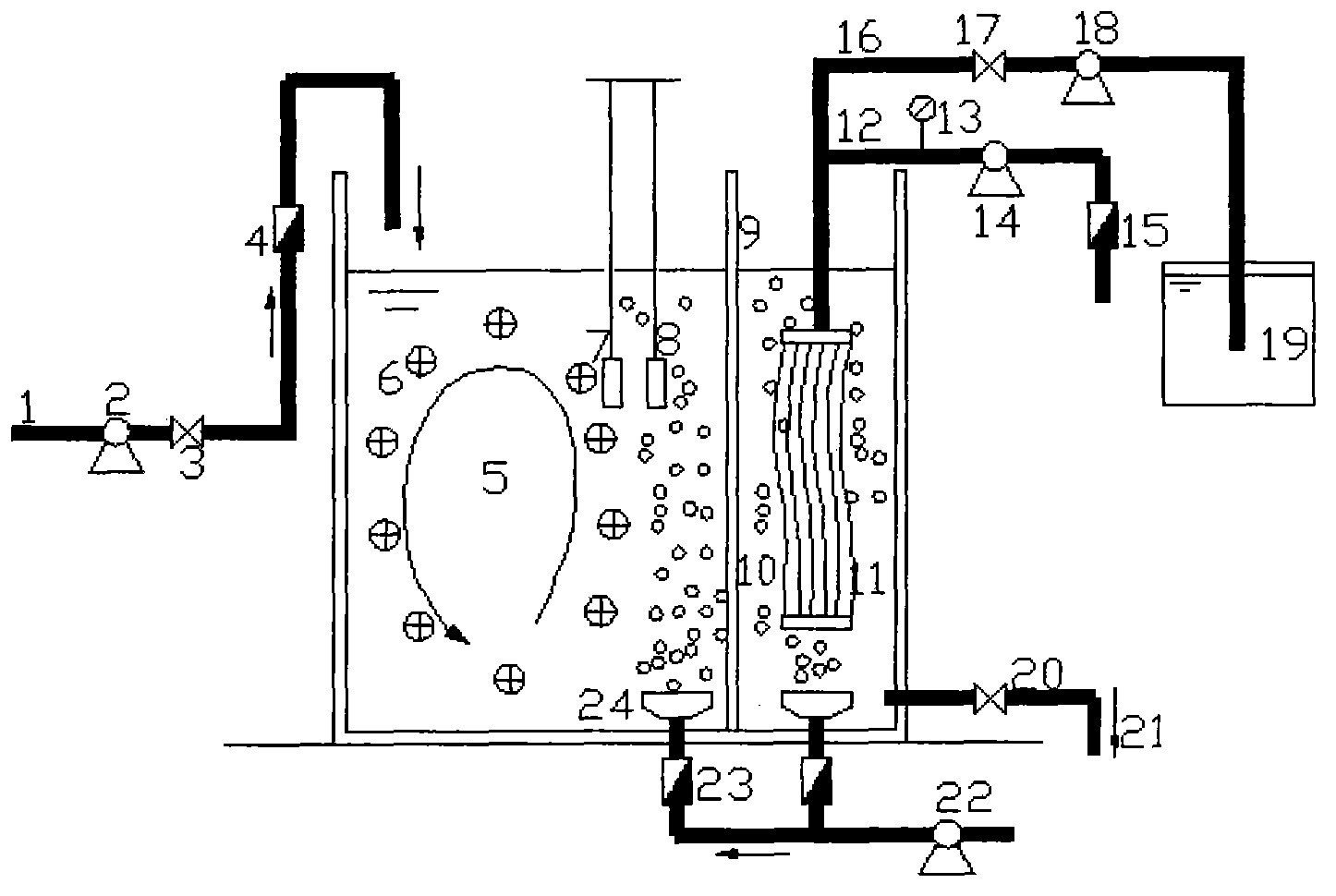

[0029] The technical solution of the present invention will be further described in detail with the accompanying drawings, but the present invention is not limited to these embodiments.

[0030] In the present invention, a perforated partition is arranged in the traditional membrane bioreactor, which is divided into two independent pool bodies of an aeration tank and a membrane tank, and a high-quality suspension carrier is added to the aeration tank.

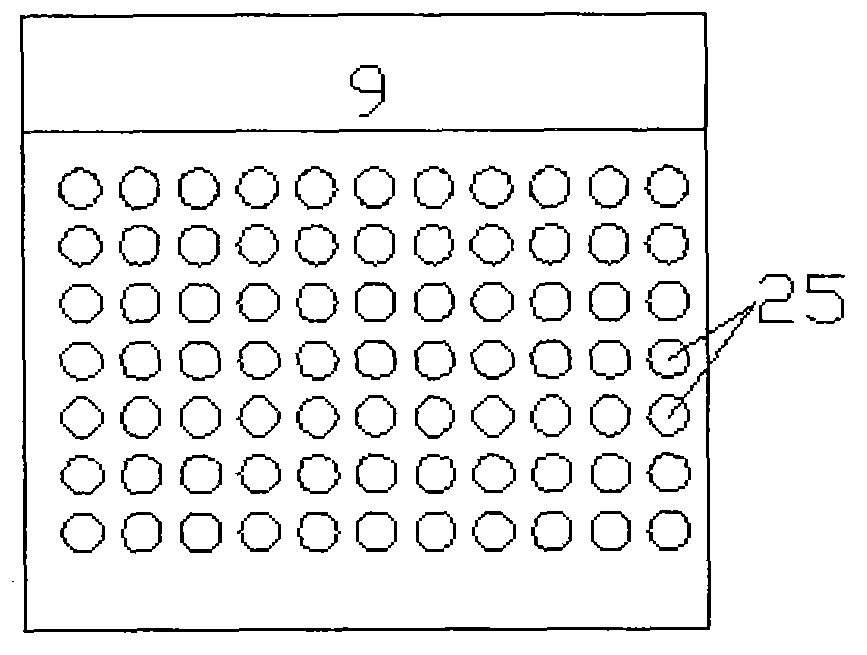

[0031] Such as figure 1 and figure 2 As shown, the traditional membrane bioreactor is to directly place the membrane module in the aeration tank to form an integrated reactor, but the present invention adopts the separator 9 with the water distribution round hole 25 to separate the traditional membrane bioreactor into aeration tanks. Air tank 5 and membrane tank 10, and add high-quality suspended filler 6 in the aeration tank 5, such as Kaldnes K 3 Type biological filler. The aeration tank 5 is provided with a water inlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com