Clamp for holding vessels

A clamp and container technology, applied in the field of clamps for holding containers, can solve the problems of unsatisfactory, difficult cleaning and disinfection of the cavity, complicated structure of the grabbing arm, etc., and achieve the effect of achieving shape stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

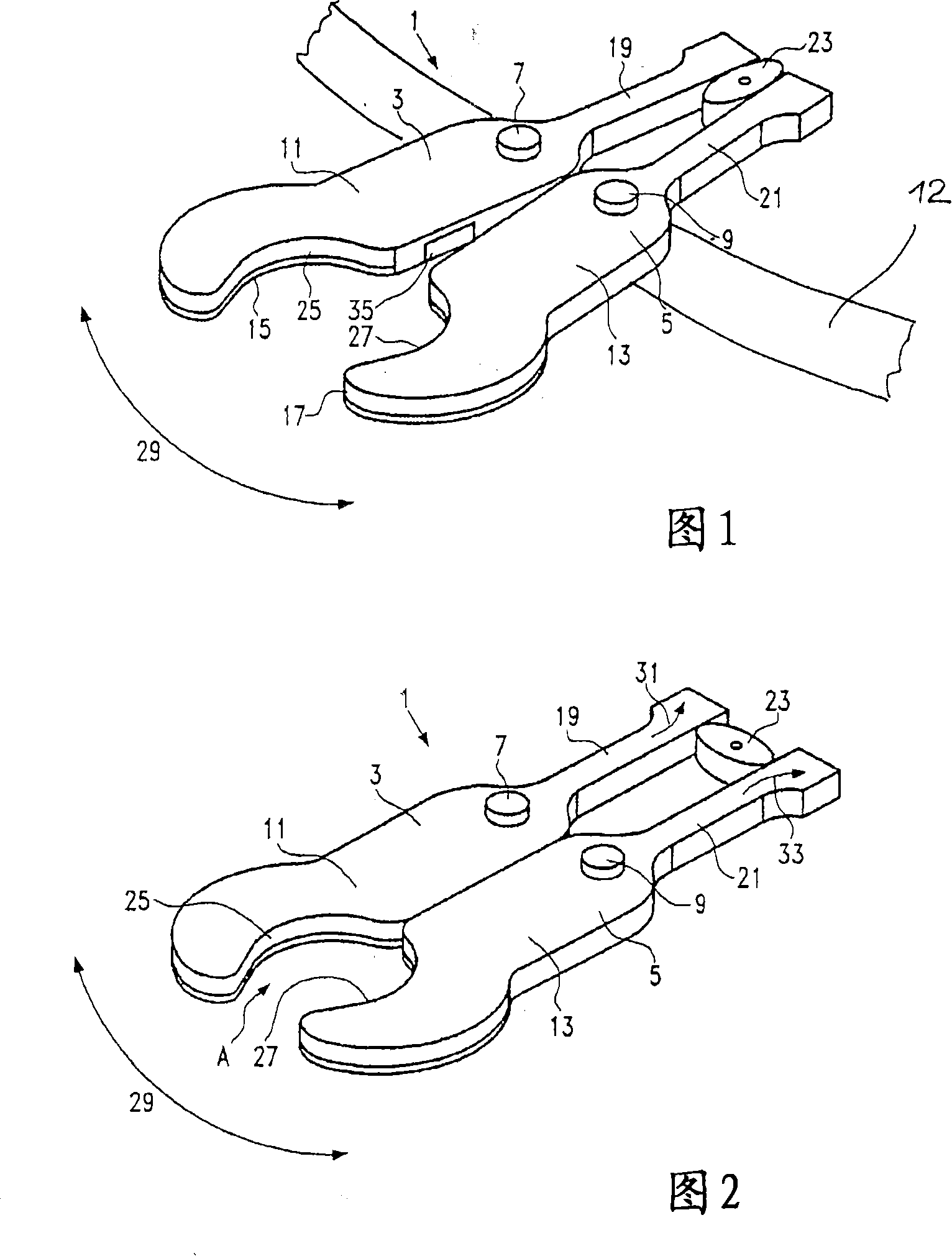

[0021] A gripper 1 for gripping containers, in particular bottles, is shown in FIGS. 1 and 2 . The gripper 1 is generally used for conveying and sorting containers in conveying stars, which are used, for example, at the outlet of bottle handling machines such as filling or inspection machines.

[0022] FIG. 1 shows a transfer star 12 on which the gripper 1 is rotatably fastened by means of pins 7 , 9 . The teleportation star is preferably made of stainless steel, but other materials are also conceivable. The fixation of the clamp 1 is obviously not limited to transporting stars. Of course, fastening to chain links, belts and other conveying devices is also possible.

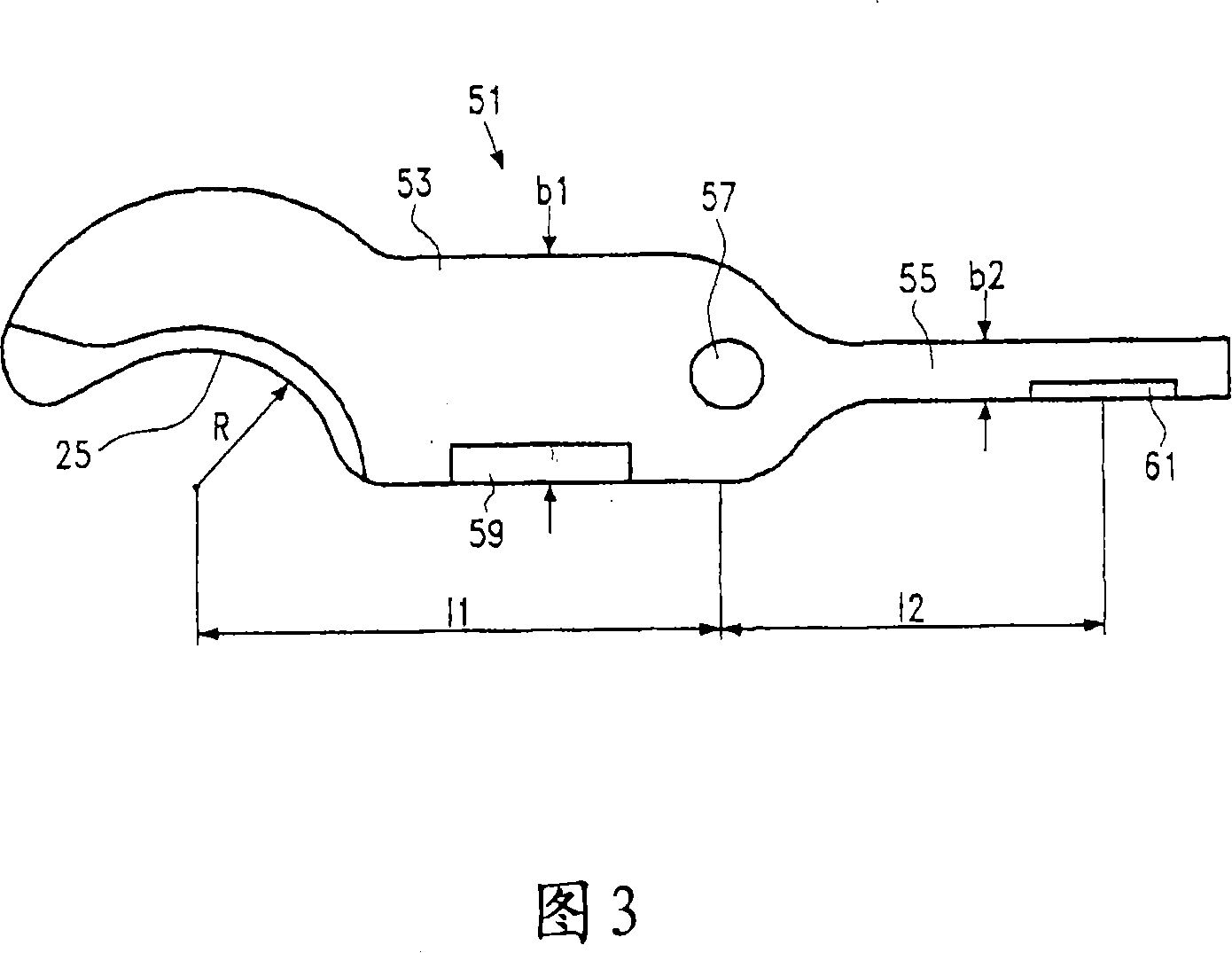

[0023] In the first embodiment the gripper 1 comprises two mirror-symmetrical gripper arms 3 and 5 . The gripper arms 3 and 5 are mounted rotatably on a pin 7 and 9, respectively. Each one-piece clamping arm 3 , 5 has a gripper arm 11 or 13 , the ends of which are each curved in order to be able to enclose th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com