Centering device

A technology of centering device and centering block, applied in the direction of spraying device, etc., can solve the problems of affecting product quality, the deviation of the center line of the non-stick pan and the center line of the suction cup, the deviation of the position of the non-stick pan and the theoretical position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

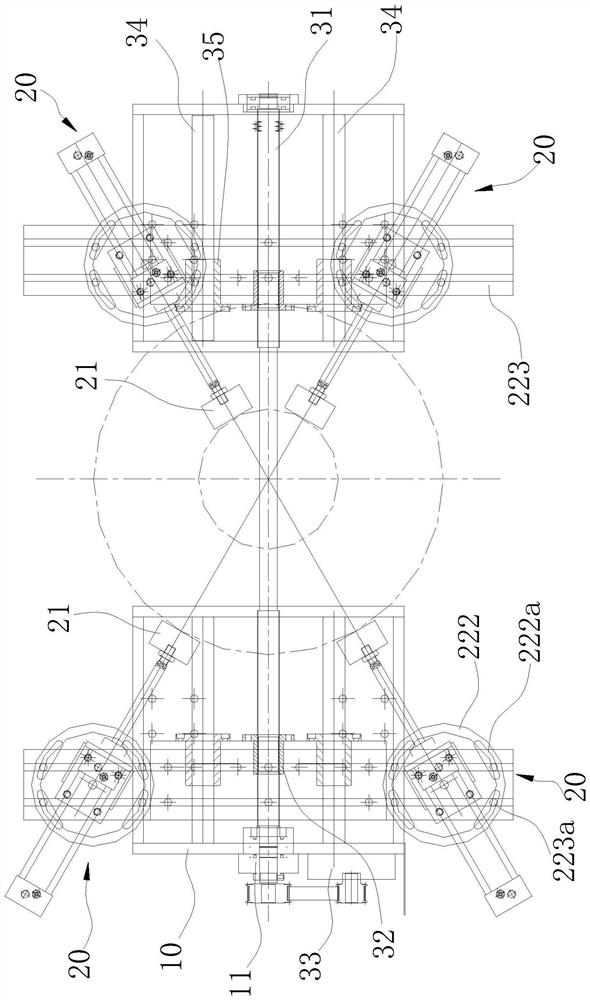

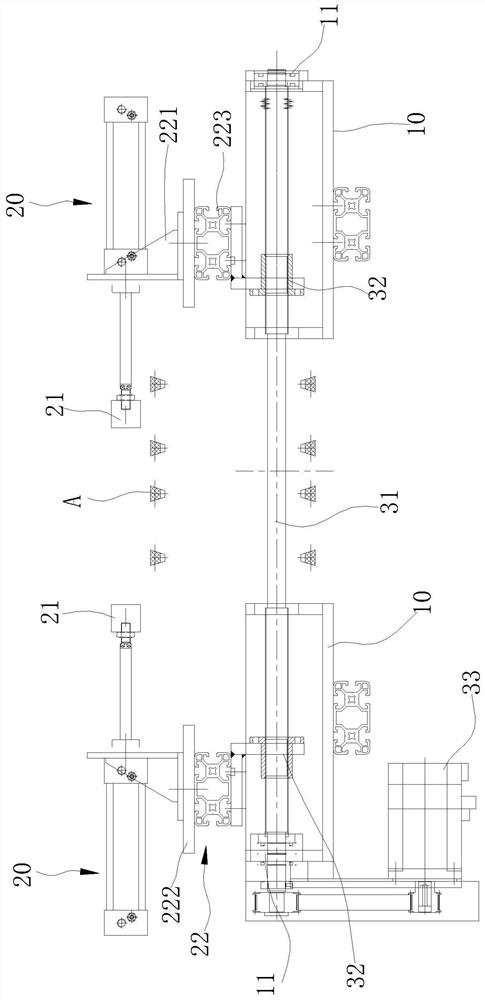

[0009] Such as figure 1 , figure 2 As shown, a centering device, at least three centering blocks 21 are arranged on the frame 10 on both sides of the conveying unit A, the centering blocks 21 are connected with the driving mechanism and move in the same horizontal plane, and multiple centering blocks 21 move When being on the same circle with different radii determined by the center of the circle (the meaning is that the center of the circle is determined, there can be multiple circles with different radii, and the three centering blocks 21 can be on the same circle with different radii when they move. The inner surface of the centering block 21 facing the center of the circle is a plane (each inner surface is tangent to the same circle), and the bottom of the centering block 21 is higher than the conveying unit A. The drive mechanism here can be a linear drive mechanism or a swing drive mechanism or other forms, as long as the drive to the centering block 21 can be realized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com